Concrete foundation pit supporting and monitoring construction technique based on axial force servo system

A technology of servo system and foundation pit support, which is applied in foundation structure engineering, foundation structure test, excavation, etc., and can solve problems such as high quality requirements, non-conforming to green construction, and high technical requirements for construction and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

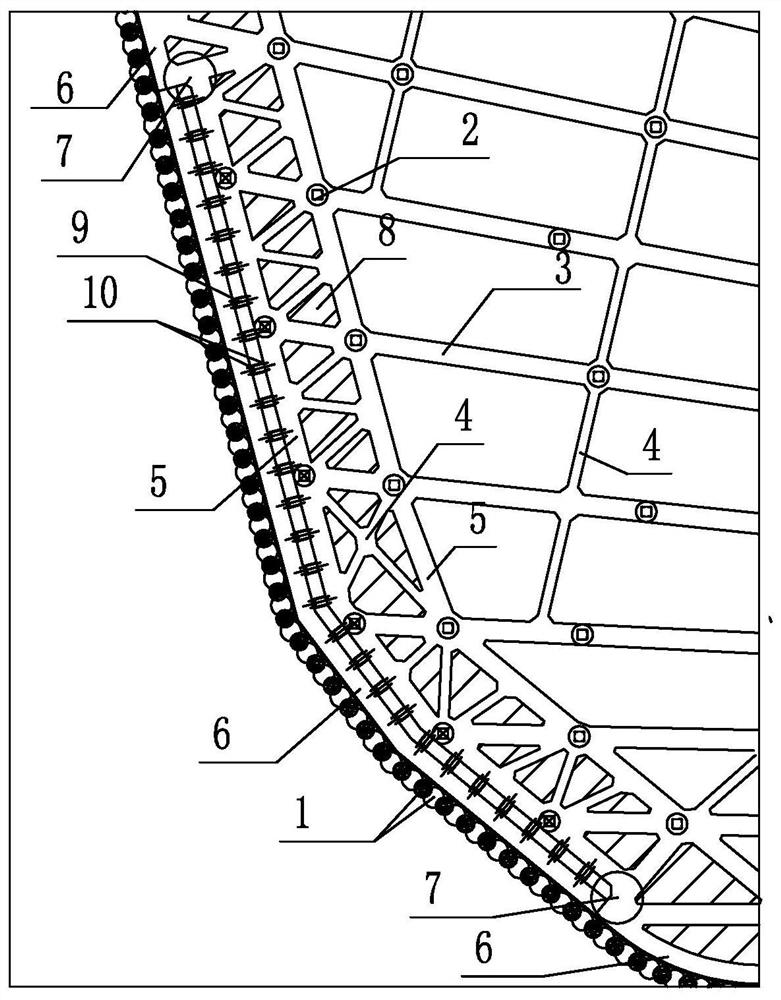

[0067] A concrete foundation pit support and monitoring construction technology based on an axial force servo system, including:

[0068] S1. Construction preparation

[0069] Review and approve the foundation pit support construction plan, calculate the axial force loaded by the axial force servo system of each layer, the structural parameters of the supporting beam, the type of the enclosure structure and the construction parameters, and the design drawings shall be reviewed and confirmed by the drawing review unit;

[0070] S2. Construction of foundation pit enclosure structure

[0071] S21. Underground diaphragm walls and occlusal piles are often used in the construction of foundation pit support and enclosure structures;

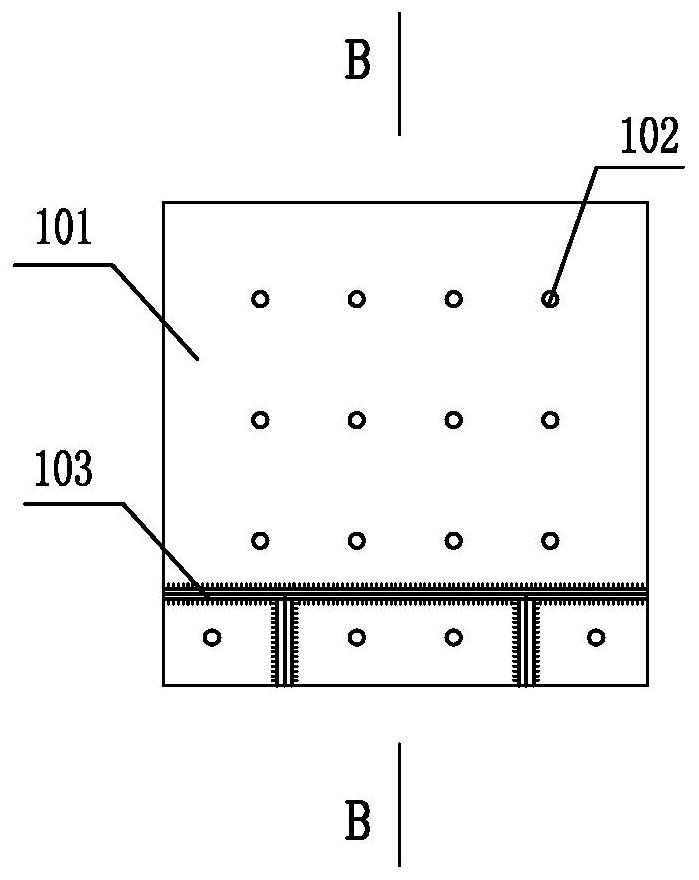

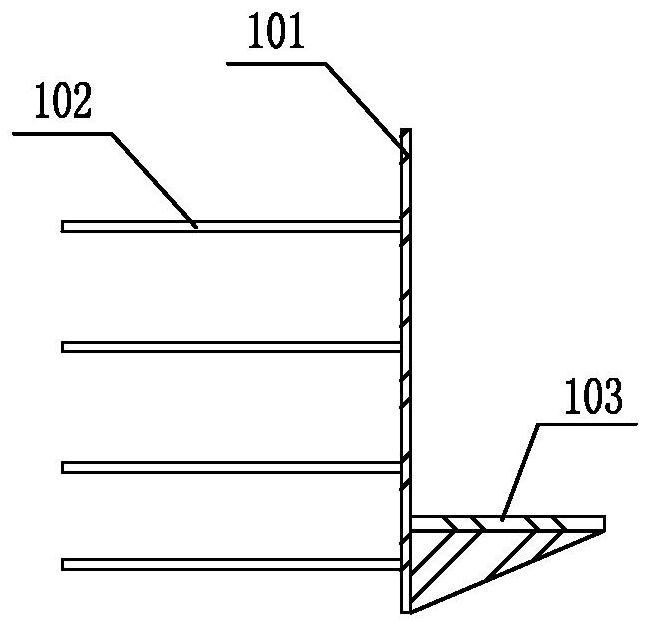

[0072] S22. The load-bearing column of the inner support adopts a steel structure lattice column, and the hole is formed by a rotary excavator. The concrete end bearing pile is used below the foundation, and the steel structure lattice column is anchor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com