A kind of multiphase organic waste comprehensive feed pyrolysis device

An organic waste, feeding device technology, applied in the direction of educts, by-product vaporization, lighting and heating equipment, etc., can solve problems affecting the stability and continuity of back-end processing devices, lack of stable and efficient feeding methods, waste To deal with problems such as increasing difficulty, to achieve the effects of continuous, uniform and stable feeding, compact and reasonable device design, and enhanced air tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, detailed description will be given below with reference to the accompanying drawings and specific embodiments.

[0038] Aiming at the existing problems, the present invention provides a multiphase organic waste comprehensive feeding pyrolysis device, which is ingenious in design, simple in operation and maintenance, can realize uniform feeding of multiphase organic waste in pyrolysis, and effectively improve the thermal solution efficiency.

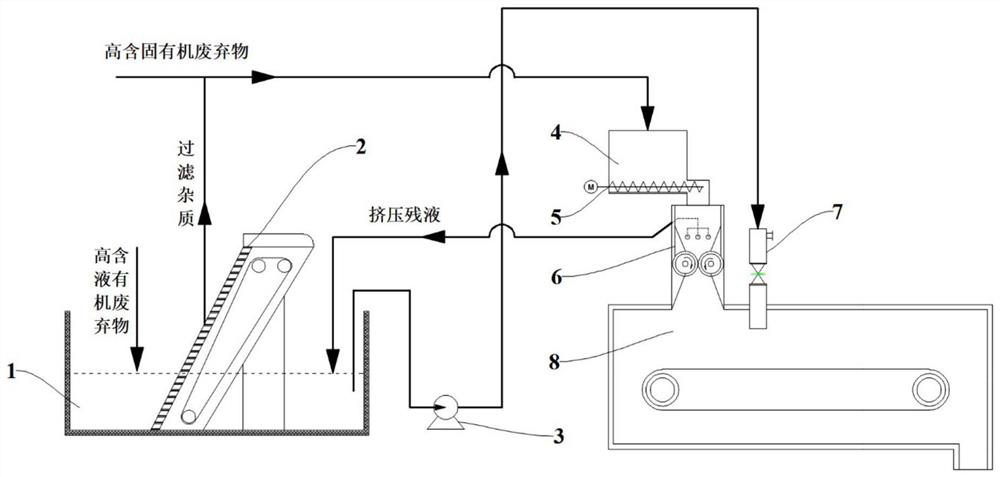

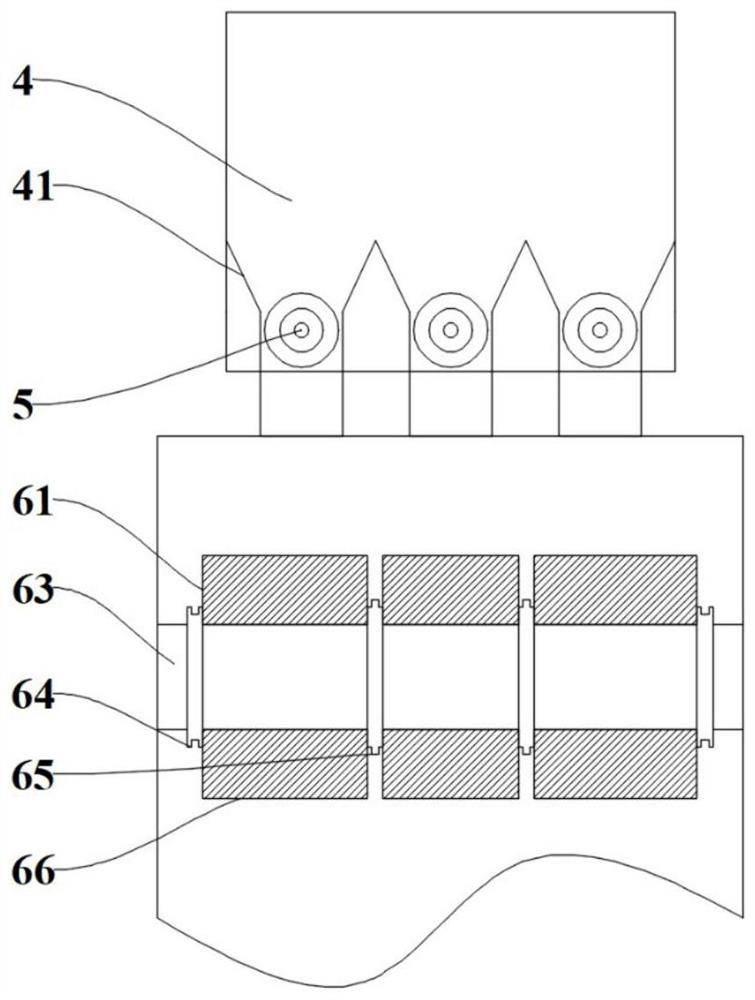

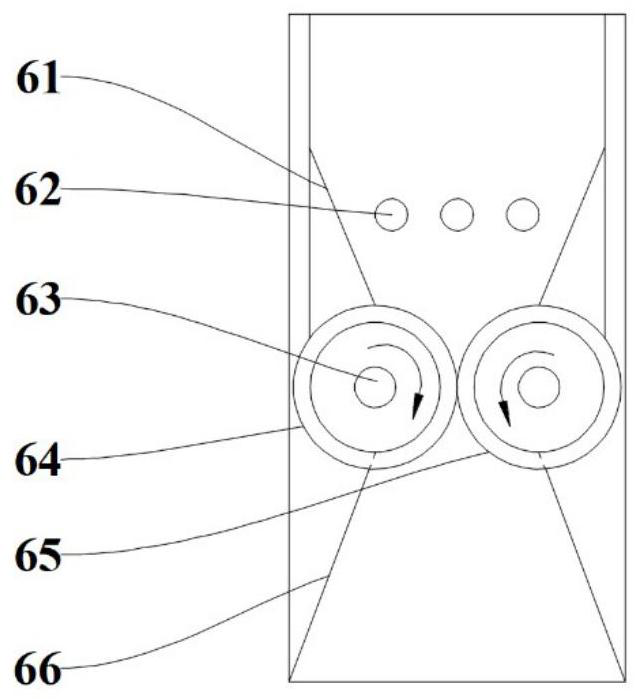

[0039] In order to realize the above technical solutions, such as figure 1 As shown, the embodiment of the present invention provides a multiphase organic waste integrated feed pyrolysis device, including a slurry storage tank 1, a grid 2, an oil pump 3, a silo 4, a screw feeder 5, a pair of rollers type extrusion feeding device 6, slurry feeding device 7 and chain plate type pyrolysis device 8; wherein:

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com