Rotary cone high-performance smashing and grinding machine

A grinder and rotary technology, which is applied in the direction of grain processing, etc., can solve the problems such as the reduction of the crushing effect of the grinder blade, high moisture content, poor adaptability, etc., and achieve the effect of improving the crushing and grinding effect, improving the fermentation efficiency, and extending the distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

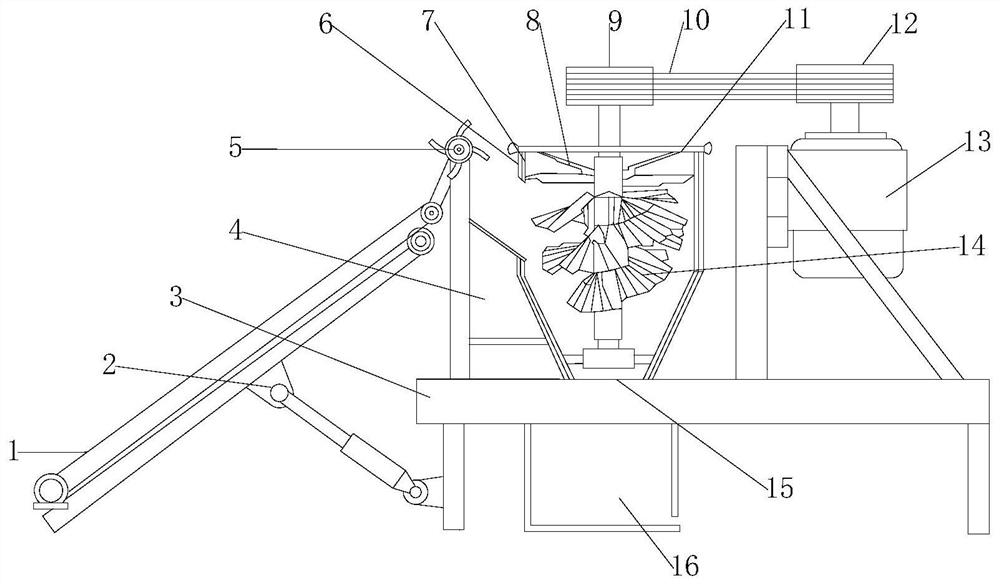

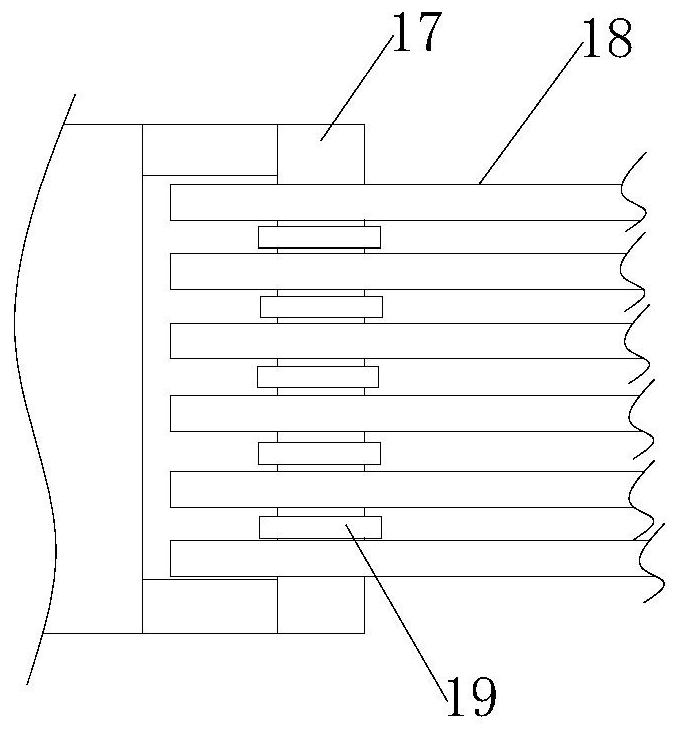

[0059]Such asfigure 1 As shown, a high performance pulverizing mill, including housing 6 and a rotating abrasive core, wherein the housing comprises a constant diameter segment and a diameter section, a large diameter end and a constant diameter section. One end is connected, the top or side surface of the constant diameter segment is provided with a feed port, a small diameter end of the reduced diameter segment, forming a lower body opening; the top of the housing is provided with a rotating pressurizing device, the rotating pressurizing device The fan blade is provided with a ventilated structure at the inside of the housing and the blade of the housing. By setting the air structure, it is used with the rotating pressurizing device, and the powder, the resulting dust, the slurry, and the like can be transferred smoothly, and collect it.

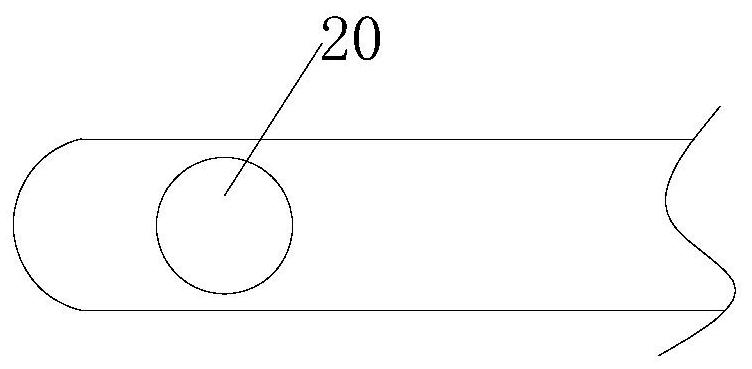

[0060]The rotating abrasive core includes a rotating shaft and a plurality of array of artificial knives, and both ends of the rotating shaft are ...

Embodiment 2

[0067]Such asfigure 1 As shown, a pulverized abrasive system includes the rotary cone grinder, a stent 3, a feed apparatus 1, a storage tank 16, and a motor 13, a rotary cone grinder mounted on a stent 3, a feed device 1 The lower portion of the lower body corresponding to the feed port of the rotary cone grinder, the output shaft of the motor 13 is connected to one end of the rotation shaft of the rotary cone grinder by the transmission belt 10; the storage box 16 is disposed in a rotary type The lower body of the cone grinder is below the mouth.

[0068]Also included, the biosaramia 4 is provided on the bracket 3, and the biorestallow 4 communicates with the housing of the rotary cone grinder. Biofia is added thereto during the crushing of vegetable waste, which is conducive to improving the degree of mixing uniformity of the biofacial and vegetable waste, thereby conducive to subsequent fermentation and saving operational steps.

[0069]The feed device 1 is provided with a dielectric d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com