Tantalum target material and treatment method of sputtering surface of tantalum target material

A processing method and tantalum target technology, applied in the field of sputtering targets, can solve problems such as uneven grinding, sputtering surface deformation, edge collapse, etc., and achieve the effects of avoiding grinding wheel grinding, improving target quality, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

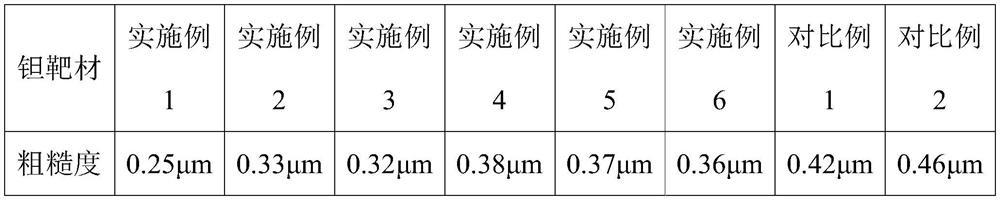

Examples

Embodiment 1

[0044] This embodiment provides a processing method for a tantalum target and its sputtering surface, the processing method includes turning and polishing successively.

[0045] In this embodiment, the turning is to use a blade with a specification of CCGX120404H10 to feed the knife from the edge to the center along the diameter direction of the tantalum target, and the speed of the knife is 0.2mm / min, and the linear speed of turning is 275m / min; The turning process is accompanied by the flushing and cooling of the cutting surface of the target with Caltex 3380 cutting fluid with a mass concentration of 5%.

[0046] In this embodiment, the turning includes the rough turning with a knife engagement of 0.15mm and the finish turning with a knife engagement of 0.05mm successively, and the knife engagement is kept constant during the rough turning and finish turning; Turning includes 10-cut turning, and the allowance for fine turning is 0.45mm.

[0047] In this embodiment, the pol...

Embodiment 2

[0050] This embodiment provides a processing method for a tantalum target and its sputtering surface, the processing method includes turning and polishing successively.

[0051] In this embodiment, the turning is to use a blade with a specification of CCGX120404H10 to feed from the edge to the center along the diameter direction of the tantalum target, and the feed speed is 0.1mm / min, and the turning speed is 250m / min; The turning process is accompanied by the flushing and cooling of the cutting surface of the target with Caltex 3380 cutting fluid with a mass concentration of 8%.

[0052] In this embodiment, the turning includes the rough turning with a knife engagement of 0.13mm and the finishing turning with a knife engagement of 0.03mm successively, and the knife engagement is kept constant during the rough turning and finishing turning; the finishing Turning includes 12-cut turning, and the allowance for fine turning is 0.3mm.

[0053] In this embodiment, the polishing pr...

Embodiment 3

[0056] This embodiment provides a processing method for a tantalum target and its sputtering surface, the processing method includes turning and polishing successively.

[0057] In this embodiment, the turning is to use a blade with a specification of CCGX120404H10 to feed from the edge to the center along the diameter direction of the tantalum target, and the feeding speed is 0.3mm / min, and the turning speed is 300m / min; The turning process is accompanied by the flushing and cooling of the cutting surface of the target with Caltex 3380 cutting fluid with a mass concentration of 10%.

[0058] In this embodiment, the turning includes the rough turning with the knife engagement of 0.17mm and the finish turning with the knife engagement of 0.07mm successively, and the knife engagement is kept constant during the rough turning and finishing turning; Turning includes 8-cut turning, and the allowance for fine turning is 0.6mm.

[0059] In this embodiment, the polishing process is t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com