Detection tool for detecting cracking position of connecting rod

A technology of expanding and breaking connecting rods, applied in measuring devices, mechanical devices, mechanical measuring devices, etc., can solve the problems of high labor intensity, inability to quantitatively analyze the error value, and inability to quantitatively analyze the specific value of the error value, so as to reduce the production cost. Cost, convenient detection, the effect of reducing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

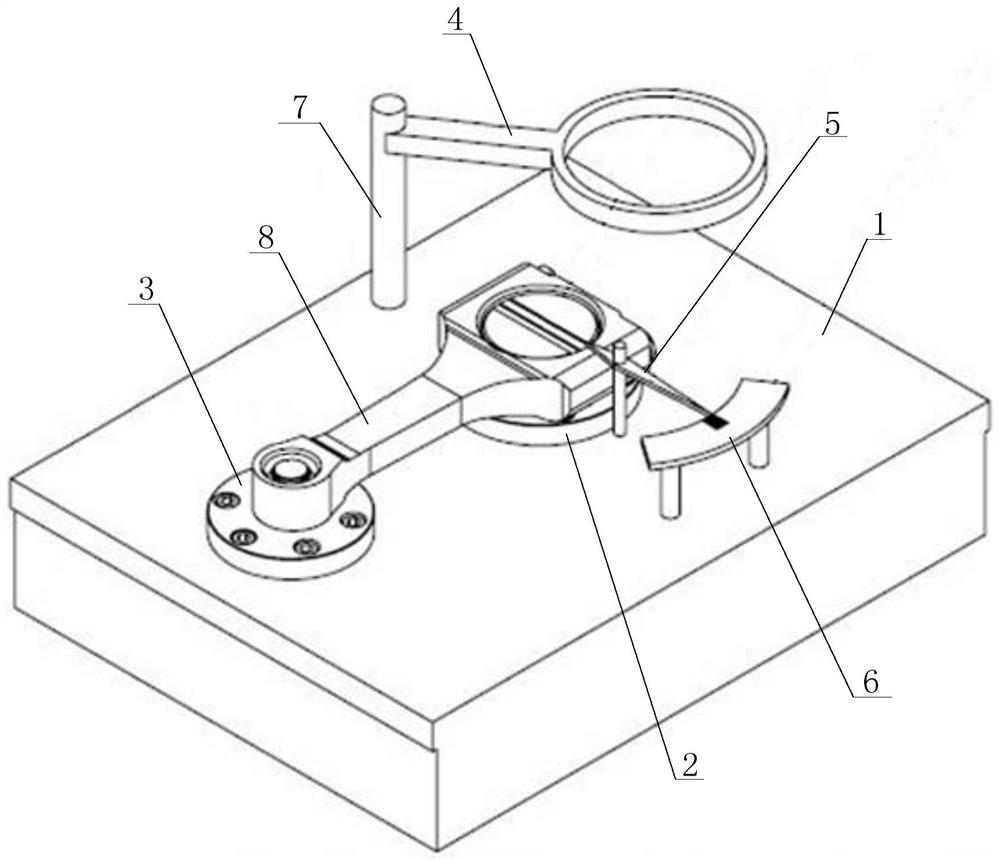

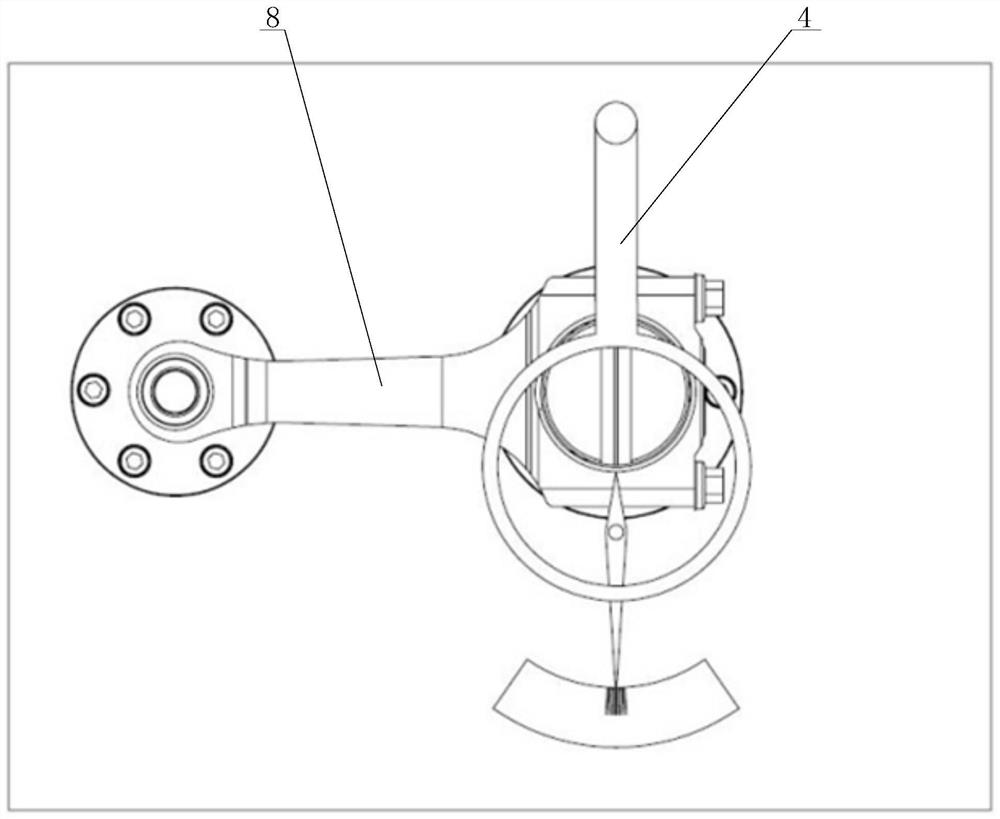

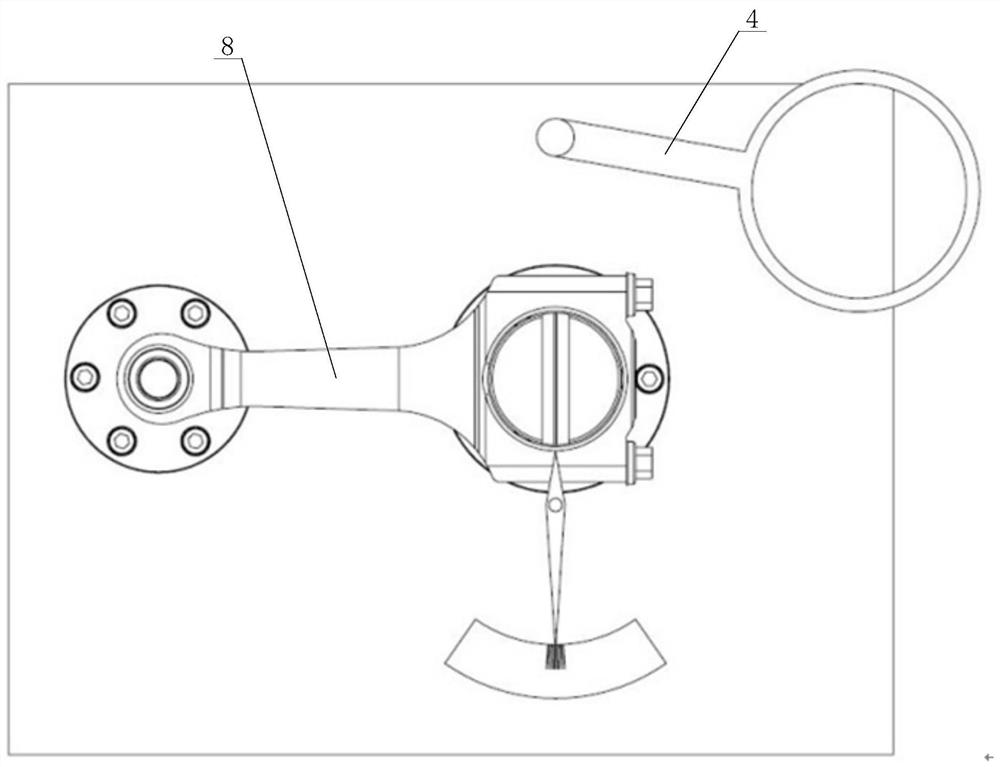

[0030] Below according to the accompanying drawings Figure 1 to Figure 8 , give a preferred embodiment of the present invention, and give a detailed description, so that the functions and characteristics of the present invention can be better understood.

[0031] see Figure 1 ~ Figure 3, a checker for checking the breaking position of a connecting rod according to an embodiment of the present invention, comprising a base 1, and a first automatic core expansion mechanism 2 connected to the base 1, a second automatic core expansion mechanism 3, and a magnifying glass 4 , a pointer 5 and a dial 6; the first automatic core expansion mechanism 2 and the second automatic core expansion mechanism 3 are arranged at intervals along a first direction; a connecting end of the magnifying glass 4 can rotate around a support shaft 7 and pass through the support shaft 7 is connected to one side of the first automatic core expansion mechanism 2; the pointer 5 and the dial 6 are arranged on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com