Fattening sheep concentrate supplement, preparation method and feeding method applied to fattening sheep

A technology of fattening sheep and supplementary feed, applied in the direction of bacteria used in food preparation, application, animal feed, etc., can solve the problems of rumen dysfunction of mutton sheep, affecting the growth performance of fattening sheep, and low feed digestibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

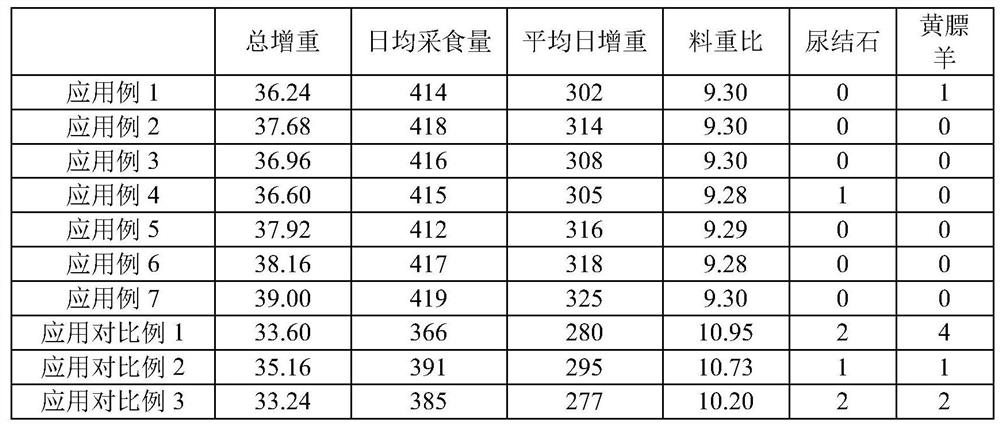

Examples

Embodiment 1

[0041] A supplementary feed for fattening sheep, which is prepared through the following steps:

[0042] Weigh corn flour, soybean meal, palm meal, corn germ meal, sprayed corn bran, rice bran and ammoniated straw into a mixer according to the parts by weight shown in Table 1, stir and mix evenly to obtain material A;

[0043] Take cane molasses, DDGS, lysine slag, superfine calcium carbonate, salt, sweetener, ammonium chloride, ruminant multivitamin, mineral additives and sodium bicarbonate and add in another blender by weight parts shown in Table 1 , stir and mix evenly to obtain material B;

[0044] Add material B into the mixer of material A, stir and mix evenly, then add Lactobacillus plantarum, and mix evenly.

Embodiment 2-7

[0046] The fattening sheep essence supplement of Examples 2-7 has the same preparation method as that of Example 1, the difference is that each raw material is added according to the dosage shown in Table 1.

[0047] The raw material dosage (unit: kg) of the fattening sheep essence feeding material of table 1 embodiment 1-7

[0048]

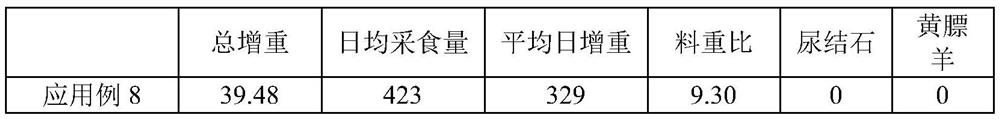

Embodiment 8

[0076] The fattening sheep essence feeding material of embodiment 8, its difference with embodiment 7 is, superfine calcium carbonate is carried out as follows in advance: take by weighing 100kg superfine calcium carbonate, dry 30min under 100 ℃; Add in the kneader, in 1600r When the stirring speed of / min stirs superfine calcium carbonate, spray into 500g stearic acid with the mode of atomization spraying, continue to stir 10min, discharging, standby; %, all the other are consistent with embodiment 7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com