Pretreatment device and pretreatment method for rural sewage

A pretreatment device and rural sewage technology, applied in water/sewage treatment, multi-stage water/sewage treatment, water/sewage treatment equipment, etc., can solve problems affecting sewage treatment, blockage, breakage, etc., to improve the treatment effect, Increase the effect of disturbance and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

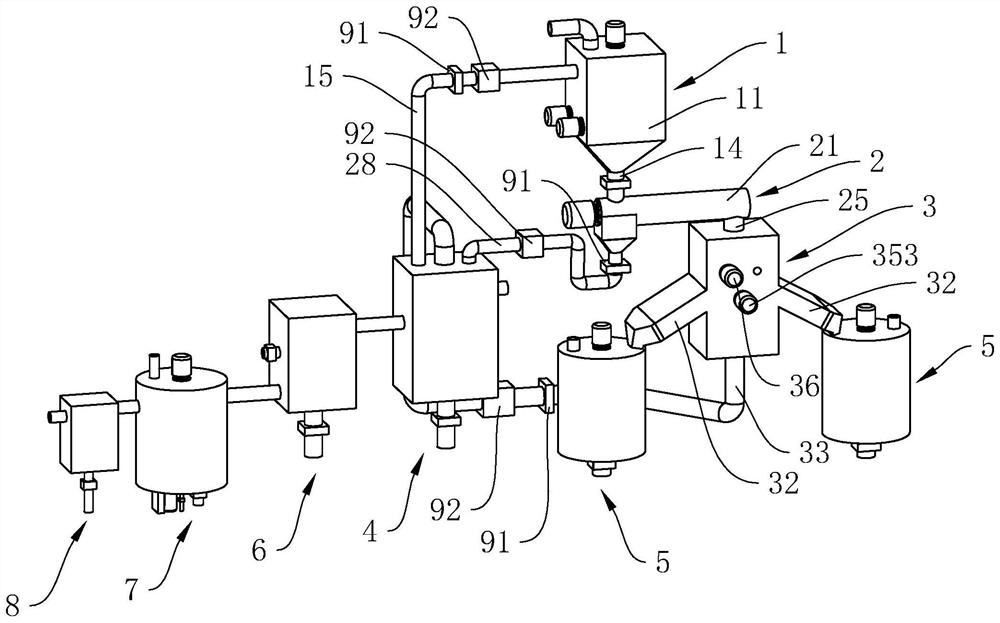

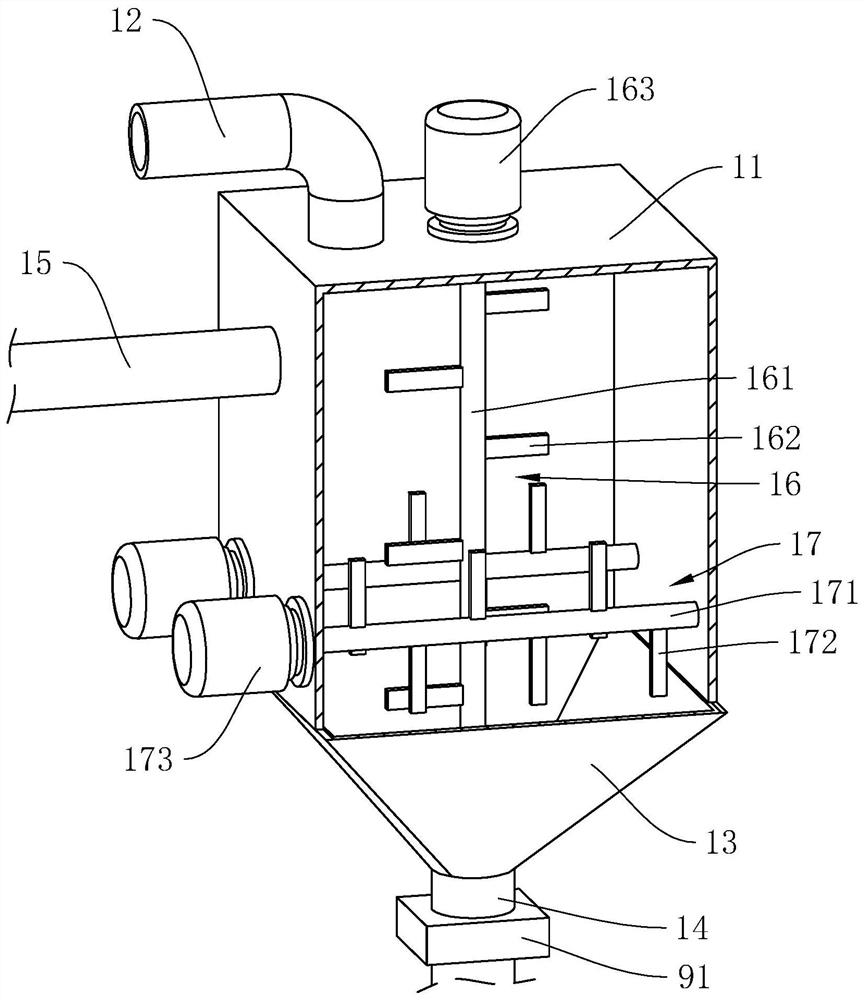

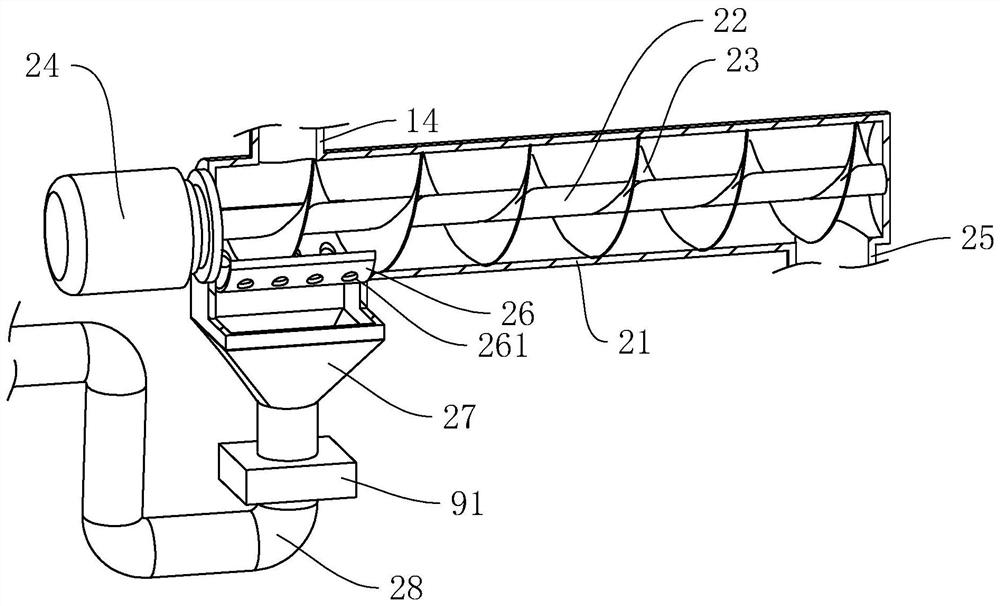

[0055] The embodiment of the present application discloses a pretreatment device for rural sewage. refer to figure 1 , comprising a collection mechanism 1, a first separation mechanism 2 is arranged downstream of the collection mechanism 1, a crushing mechanism 3 and a first sedimentation mechanism 4 are arranged downstream of the first separation mechanism 2, and a fermentation mechanism 5 is arranged downstream of the crushing mechanism 3. A second separation mechanism 6 is arranged downstream of the first sedimentation mechanism 4 , an aerobic mechanism 7 is arranged downstream of the second separation mechanism 6 , and a second sedimentation mechanism 8 is arranged downstream of the aerobic mechanism 7 . The sewage settles in the collecting mechanism 1, and produces sediment and oily waste water. The sediment passes through the first separation mechanism 2 to form muddy water and solid waste, and the solid waste is discharged after passing through the crushing mechanism 3...

Embodiment 2

[0074] The embodiment of the present application discloses a pretreatment method for a rural sewage pretreatment device, including the following steps:

[0075] The sewage is collected and deposited for the first time by the collection mechanism 1, producing oily waste water and sediment;

[0076] The sediment is separated by the first separation mechanism 2 to generate muddy water and solid waste;

[0077] The solid waste is crushed by the crushing mechanism 3 to produce muddy water and crushed solid waste;

[0078] The crushed solid waste is fermented through the fermentation mechanism 5;

[0079] Mix the oily wastewater generated by the collection mechanism 1, the muddy water generated by the first separation mechanism 2, and the muddy water generated by the crushing mechanism 3, and conduct second precipitation through the first sedimentation mechanism 4 to generate sludge and oily wastewater;

[0080] The oily waste water is separated by the second separation mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com