a high gain ho 3+ /tm 3+ /yb 3+ Co-doped silica fiber and its preparation method

A quartz fiber, high gain technology, applied in the field of optical fibers, can solve the problems of low unity gain and low solubility of rare earth ions in quartz fibers, and achieve the effects of high damage resistance threshold power, low unity gain, and low fiber impurity concentration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

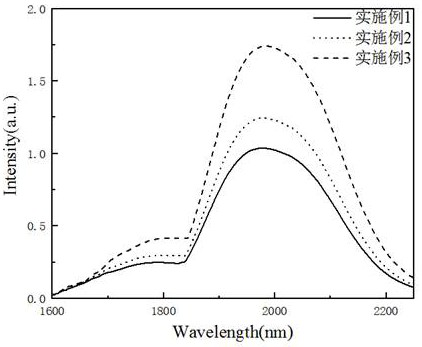

Embodiment 1

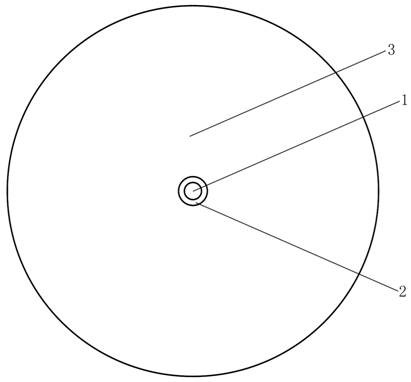

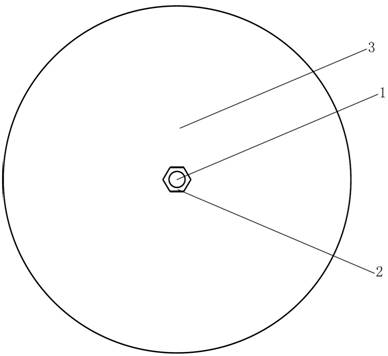

[0033] The present invention provides a high gain HO 3+ / TM 3+ / YB 3+ A common-doped-doped-doped fiber, which includes the following steps:

[0034] Step (1): The raw materials of the core layer, the inner clad layer, and the outer clad layer are referred to, respectively, as shown in Table 1;

[0035] Step (2): With oxygen as a carrier gas, uniformly flow into the quartz tube, and deposit the preform outer cladding in the surface of the quartz pipe in the surface of the quartz tube in the quartz pipe.

[0036] Step (3): With oxygen and helium as a carrier gas, uniformly insert the inner cladding raw material into the quartz tube, uniformly deposited on the inner surface of the preformed outer cladding of the deposited rod in step (2);

[0037] Step (4): With oxygen and helium as carrier gas, the raw materials of the core layer are uniformly flowed into the quartz tube, and the improved chemical vapor deposition is used and the chelate doping technique is bonded, pre-deposited i...

Embodiment 2

[0044] The present invention provides a high gain HO 3+ / TM 3+ / YB 3+ A common-doped-doped-doped fiber, which includes the following steps:

[0045] Step (1): According to the percentage of mass, the raw materials of the core layer, the inner clad layer, and the outer classes are respectively referred to, as shown in Table 2;

[0046] Step (2): With oxygen as a carrier gas, uniformly flow into the quartz tube, and deposit the preform outer cladding in the surface of the quartz pipe in the surface of the quartz tube in the quartz pipe.

[0047] Step (3): With oxygen and helium as a carrier gas, uniformly insert the inner cladding raw material into the quartz tube, uniformly deposited on the inner surface of the preformed outer cladding of the deposited rod in step (2);

[0048] Step (4): With oxygen and helium as carrier gas, the raw materials of the core layer are uniformly flowed into the quartz tube, and the improved chemical vapor deposition is used and the chelate doping tec...

Embodiment 3

[0055] The present invention provides a high gain HO 3+ / TM 3+ / YB 3+ A common-doped-doped-doped fiber, which includes the following steps:

[0056] Step (1): According to the mass percentage, the raw material of the core layer, the inner clad layer, the outer classes, as shown in Table 3;

[0057] Step (2): With oxygen as a carrier gas, uniformly flow into the quartz tube, and deposit the preform outer cladding in the surface of the quartz pipe in the surface of the quartz tube in the quartz pipe.

[0058] Step (3): With oxygen and helium as a carrier gas, uniformly insert the inner cladding raw material into the quartz tube, uniformly deposited on the inner surface of the preformed outer cladding of the deposited rod in step (2);

[0059] Step (4): With oxygen and helium as carrier gas, the raw materials of the core layer are uniformly flowed into the quartz tube, and the improved chemical vapor deposition is used and the chelate doping technique is bonded, pre-deposited in st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com