Thermal insulation concrete with spontaneous combustion coal gangue aggregate self-compacting structure and preparation method of thermal insulation concrete

A technology for structural heat preservation and self-combustion of coal, which is applied to clay preparation devices, chemical instruments and methods, cement mixing devices, etc., and can solve problems such as complex construction, high cost, and low strength of thermal insulation concrete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

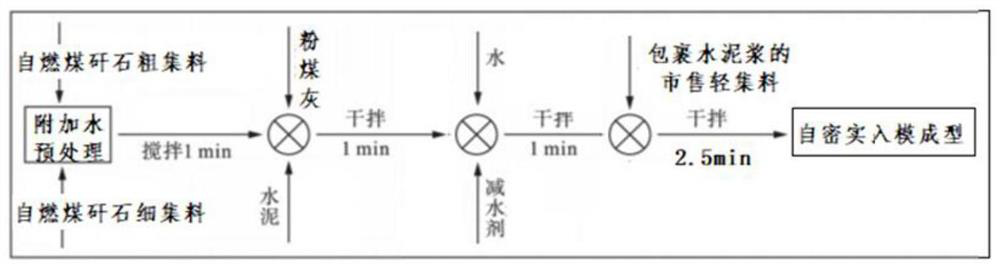

[0045] In this example, a composition and preparation method of self-combustible coal gangue fine aggregate self-compacting structure thermal insulation concrete are provided. The various components and their mass ratios are: cement: fly ash: water: natural crushed stone: Spontaneous coal gangue fine aggregate: water reducing agent=1:0.25:0.575:2.72:2.72:0.0275, the preparation method process of the embodiment of the present invention is detailed in figure 2 As shown, the preparation method comprises the following steps:

[0046] Pre-wet with additional water 1 hour before the fine aggregate of spontaneous combustion coal gangue is mixed and set aside. The amount of additional water for spontaneous combustion coal gangue fine aggregate is 60% of the water absorption rate for 1 hour;

[0047] According to the above mass ratio, dry mix the cement and fly ash in the cementitious material evenly, and set aside;

[0048] Stir polycarboxylate high-efficiency water reducer and mix...

Embodiment 2

[0056] In this example, the various components and mass ratios of the self-combustible coal gangue all-light aggregate self-compacting structure thermal insulation concrete are: cement: fly ash: water: spontaneously combustible coal gangue coarse aggregate: spontaneously combustible coal gangue fine aggregate Material: polycarboxylate high-efficiency water reducer = 1: 0.25:0.55:2.37:2.19:0.03, the preparation method process of the embodiment of the present invention is detailed in figure 2 Shown, this preparation method comprises the steps:

[0057] Additional water pre-wet treatment was carried out 1 hour before the mixing of spontaneous coal gangue coarse and fine aggregates, the additional water consumption of spontaneous combustion coal gangue coarse aggregate was 80% of the water absorption rate of 1 hour, and the additional water consumption of spontaneous combustion coal gangue fine aggregate was 60% of water absorption in 1h;

[0058] Dry mix the cementitious materi...

Embodiment 3

[0064] In this example, the various components and mass ratios of the spontaneously-combustible coal gangue aggregate self-compacting structure thermal insulation concrete are: cement: fly ash: water: spontaneously combustible coal gangue coarse aggregate: spontaneously combustible coal gangue fine aggregate: Polyphenylene particles: polycarboxylate high-efficiency water reducer = 1:0.2:0.55:2.19:1.66:0.0083:0.03, the preparation method process of the embodiment of the present invention is detailed in figure 2 Shown, this preparation method comprises the steps:

[0065] Additional water pre-wet treatment was carried out 1 hour before the mixing of spontaneous coal gangue coarse and fine aggregates, the additional water consumption of spontaneous combustion coal gangue coarse aggregate was 80% of the water absorption rate of 1 hour, and the additional water consumption of spontaneous combustion coal gangue fine aggregate was 60% of water absorption in 1h;

[0066] Mix the cem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com