Silicon carbide slurry prepared from waste silicon carbide deck and preparation method of silicon carbide slurry

A silicon carbide shed and silicon carbide technology is applied in the field of refractory materials, which can solve the problems of insufficient high temperature performance of materials, complicated preparation of binders, and large amount of clay used, and achieves high softening temperature under load, full ash seam, and high softening temperature under load. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

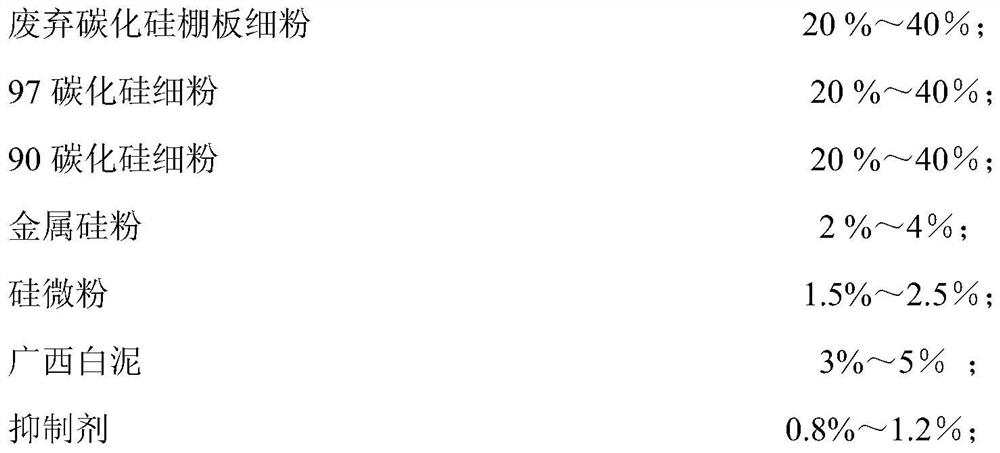

[0046] The raw material slurry of silicon carbide mud using recycled silicon carbide shed board as the main raw material is calculated by mass percentage:

[0047]

[0048]

[0049] The physicochemical index of embodiment 1 silicon carbide mud is as follows:

[0050]

Embodiment 2

[0052] The raw material slurry of silicon carbide mud using recycled silicon carbide shed board as the main raw material is calculated by mass percentage:

[0053]

[0054] The physicochemical index of embodiment 2 silicon carbide mud is as follows:

[0055]

[0056]

Embodiment 3

[0058] The raw material slurry of silicon carbide mud using recycled silicon carbide shed board as the main raw material is calculated by mass percentage:

[0059]

[0060] The physicochemical index of embodiment 3 silicon carbide mud is as follows:

[0061]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com