Preparation method of bismuth sodium bismuth titanate layered piezoelectric ceramic

A technology of bismuth, sodium, bismuth titanate and piezoelectric ceramics, which is applied in the field of piezoelectric ceramics preparation, can solve the problems of reducing the stability and reliability of sensors, reducing the high-temperature resistivity of piezoelectric ceramics, and not being suitable for large-scale industrial production. Achieve the effects of improving electrical properties, increasing high temperature resistivity, and improving piezoelectric properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032]Example 1, a method for preparing a titanate sodium laminate layer piezoelectric ceramic, and the preparation method is as follows:

[0033](1), ingredient

[0034]Put the raw material NA2CO3, BI2O3, TIO2And Co2O3, According to the following meter:

[0035]NA0.5BI4.5Ti4-xCOxO15-x / 2Mix, X = 0.05 in the formula. In the formula, from left to right of 0.5, 4.5, 4-x, X, 15-x / 2 are the molar content of the raw material. Take the total mass of 400.000g powder as an example, weigh NA2CO3, BI2O3, TIO2And Co2O3The mass was 7.586 g, 300.167 g, 91.050g and 1.197 g. (Universal in the piezoelectric ceramic industry shown above). After mixing the feedstock, it is placed in a ball mill, and the ball mill is anhydrous ethanol and agate ball, agate ball, raw material, absolute ethanol, 1.0: 0.7: 0.5, ball milling time is 8 h, ball mill frequency is 33.5 Hz; The mixture was then placed in an oven at 100 ° C, then placed in a mortar, and the mixture was formed into a mixed raw material.

[0036](2), synthe...

specific Embodiment

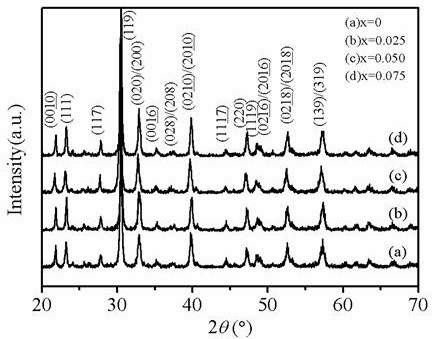

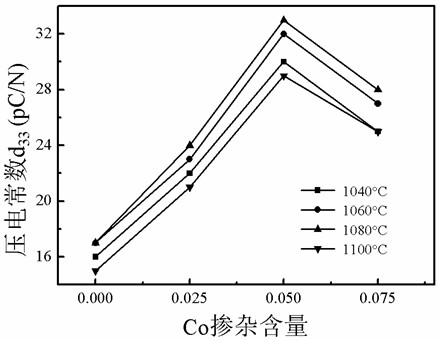

[0051]X = 0, the sintering temperature is 1040 ° C, 1060 ° C, 1080 ° C, 1100 ° C, respectively, respectively, in Examples 1-1, 1-2, 1-3, 1-4;

[0052]X = 0.025, the sintering temperature is 1040 ° C, 1060 ° C, 1080 ° C, 1100 ° C, respectively, in Examples 2-1, 2-2, 2-3, 2-4, respectively;

[0053]X = 0.050, the sintering temperature is 1040 ° C, 1060 ° C, 1080 ° C, 1100 ° C, respectively, separately as Examples 3-1, 3-2, 3-3, 3-4;

[0054]X = 0.075, the sintering temperature was 1040 ° C, 1060 ° C, 1080 ° C, 1100 ° C, respectively, respectively, in Examples 4-1, 4-2, 4-3, 4-4, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Piezoelectric constant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap