Production integrated system of ginseng enzyme, method for producing ginseng enzyme using it, ginseng enzyme and application thereof

An integrated system and enzyme technology, applied in the direction of enzyme production/bioreactor, biological material sampling method, method of supporting/immobilizing microorganisms, etc., can solve the problems of low preparation efficiency and large batch-to-batch differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

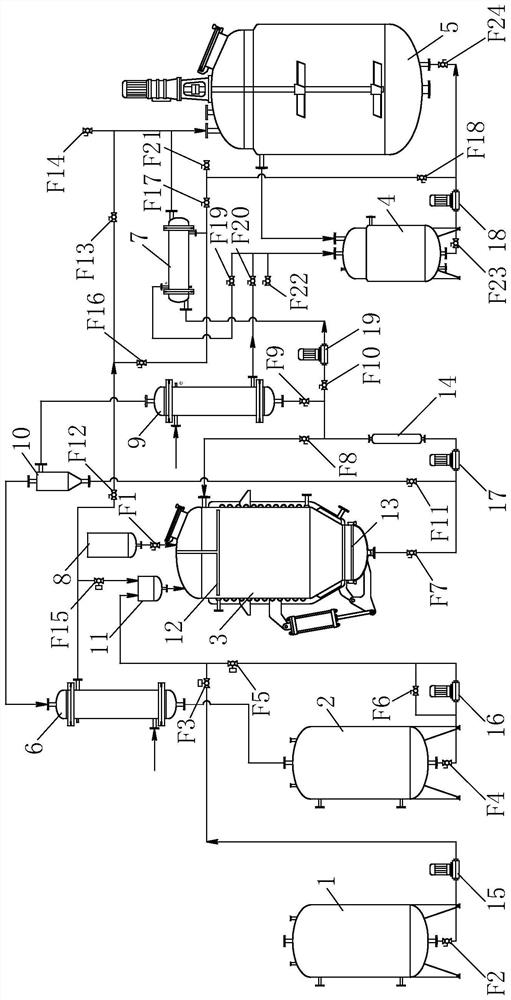

[0090] A kind of production integrated system of ginseng ferment, such as figure 1 As shown, it includes ethanol heating storage tank 1, condensate storage tank 2, extraction tank 3, hot water recovery tank 4, fermentation tank 5, condenser 6, cooler 7, enzyme mixing tank 8, heater 9, gas-liquid separation Device 10, alcohol-water mixing tank 11.

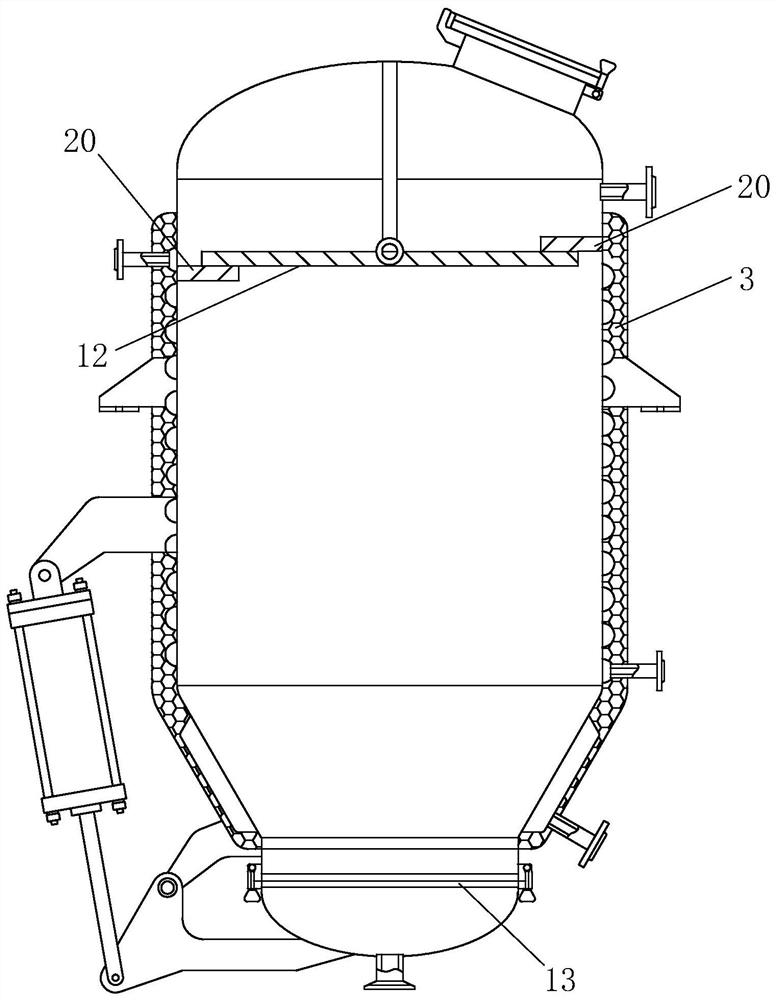

[0091] The top of the extraction tank 3 is provided with an inlet pipe for enzyme mixed liquid and an inlet pipe for alcohol-water mixed liquid, its side wall is provided with an inlet pipe for returning the extracting liquid, and the bottom is provided with an outlet for extracting liquid.

[0092] The upper part of the extraction tank 3 is provided with a flap distributor 12, which is a circular uniform structure with holes. A connecting rod extends downward from the bottom of the lid of the extraction tank 3, and the top of the connecting rod is fixed to the lid of the extraction tank 3. The bottom end is freely hinged with the ...

Embodiment 1

[0112] A kind of production method of ginseng enzyme, reference figure 1 , specifically including the following production steps:

[0113] In the fermentor 5, add glucose in the fermentation medium in advance as a carbon source and yeast powder as a nitrogen source, and inoculate 1% by volume of Lactobacillus plantarum seed solution under aseptic conditions, control the pH to 5.5, and the temperature to be 37°C.

[0114] The fermentation medium is composed of the following raw material components in parts by weight: 200 parts of concentrated solution, 20 parts of glucose and 1 part of yeast.

[0115] Concentrates and human enzymes are obtained through a process that includes the following steps:

[0116] (1) Ginseng is crushed into 5 meshes, and the crushed ginseng powder is put into the extraction tank 3, and the volume of medicinal material accounts for 60% of the volume of the extraction tank 3.

[0117] (2) Close valve F5, valve F8, valve F10, open valve F2, first deliv...

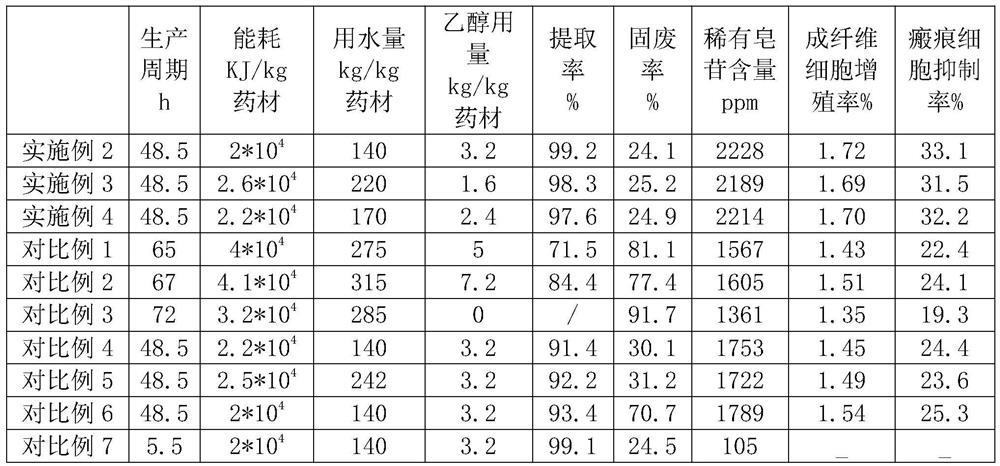

Embodiment 2

[0128] A kind of production method of ginseng enzyme differs from embodiment 2 in that it specifically comprises the following production steps:

[0129] In the fermentor 5, add glucose in the fermentation medium in advance as a carbon source and yeast powder as a nitrogen source, and inoculate 1% by volume of Lactobacillus plantarum seed solution under aseptic conditions, control the pH to 5.5, and the temperature to be 37°C.

[0130] The fermentation medium is composed of the following raw material components in parts by weight: 200 parts of concentrated solution, 20 parts of glucose and 1 part of yeast.

[0131] The concentrate and ginseng enzymes are obtained through a process comprising the following steps:

[0132] (1) Ginseng is crushed into 10 meshes, and the crushed ginseng powder is put into the extraction tank 3, and the volume of the medicinal material accounts for 70% of the volume of the extraction tank 3;

[0133] (2) Close valve F5, valve F8, valve F10, open ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com