AlSi10Mg powder and selective laser melting manufacturing process

A laser selective melting and manufacturing process technology, applied in the field of additive manufacturing, can solve the problems of expensive, unsuitable for large-scale production and application, and achieve the effect of good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] This embodiment provides a novel AlSi10Mg powder and SLM manufacturing process.

[0038] The chemical composition of the novel AlSi10Mg powder is as follows:

[0039] Si: 9.11wt%, Mg 0.30wt%, Cu≤0.05wt%, Fe: 0.11wt%, Mn: 0.37wt%, Er: 0.04at%, Zr: 0.04at%, and the balance is Al.

[0040] The new AlSi10Mg powder containing the above components was prepared by in-situ alloying by gas atomization powder production. At the same time, the powder was dried in a vacuum oven at 80°C for 8 hours before SLM manufacturing.

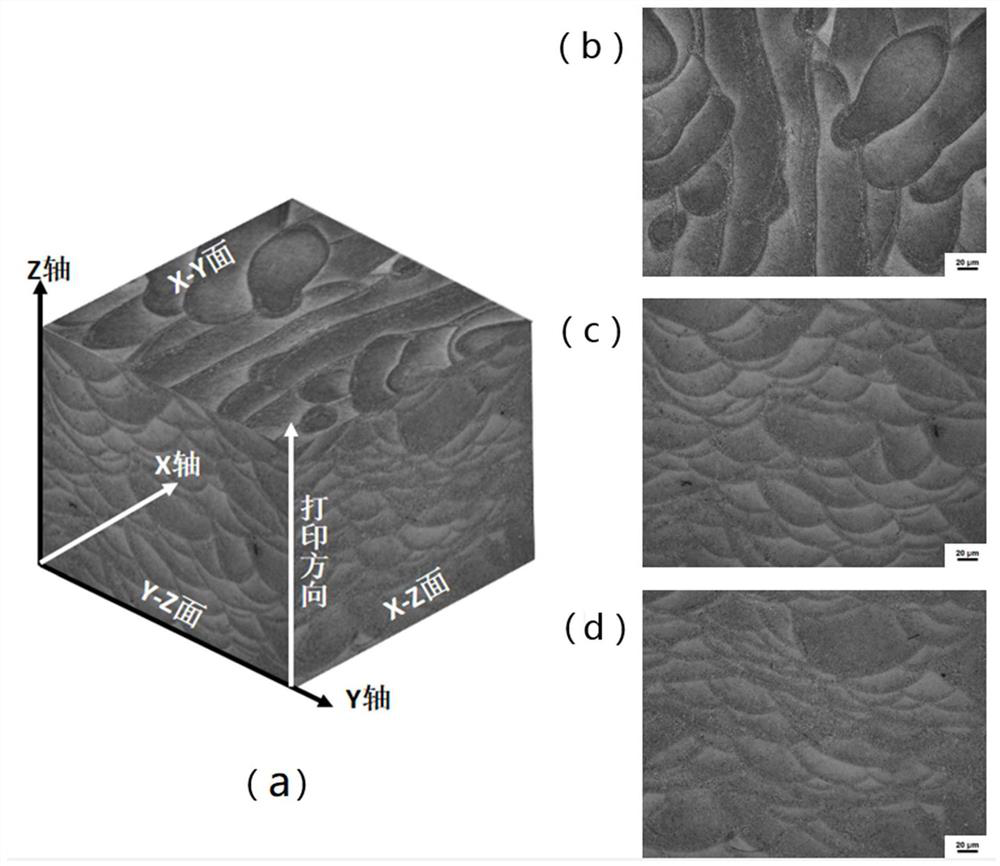

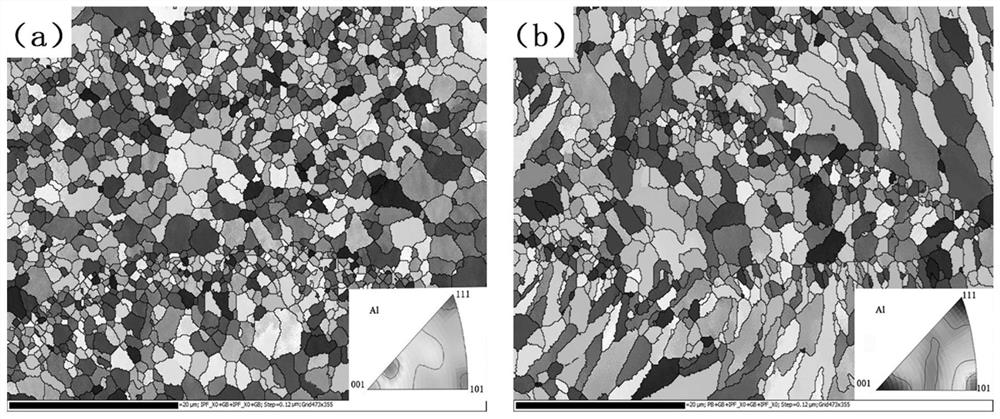

[0041] In this example, an EOS M100 metal 3D printer manufactured by Germany EOS Company was used to prepare experimental samples. After loading the dried new AlSi10Mg powder into the powder bin, adjust the height of the substrate and set the process parameters, among which the laser scanning power is 92W; the spot diameter of the laser scanning is 40 μm; the laser scanning distance is 50 μm; the thickness of the powder layer is 30 μm; The laser scanning spee...

Embodiment 2

[0047] This embodiment provides a novel AlSi10Mg powder and SLM manufacturing process.

[0048] The chemical composition of the novel AlSi10Mg powder is as follows:

[0049] Si: 7.75wt%, Mg: 0.31wt%, Cu≤0.05wt%, Fe: 0.11wt%, Mn: 0.33wt%, Er: 0.04at%, Zr: 0.04at%, and the balance is Al.

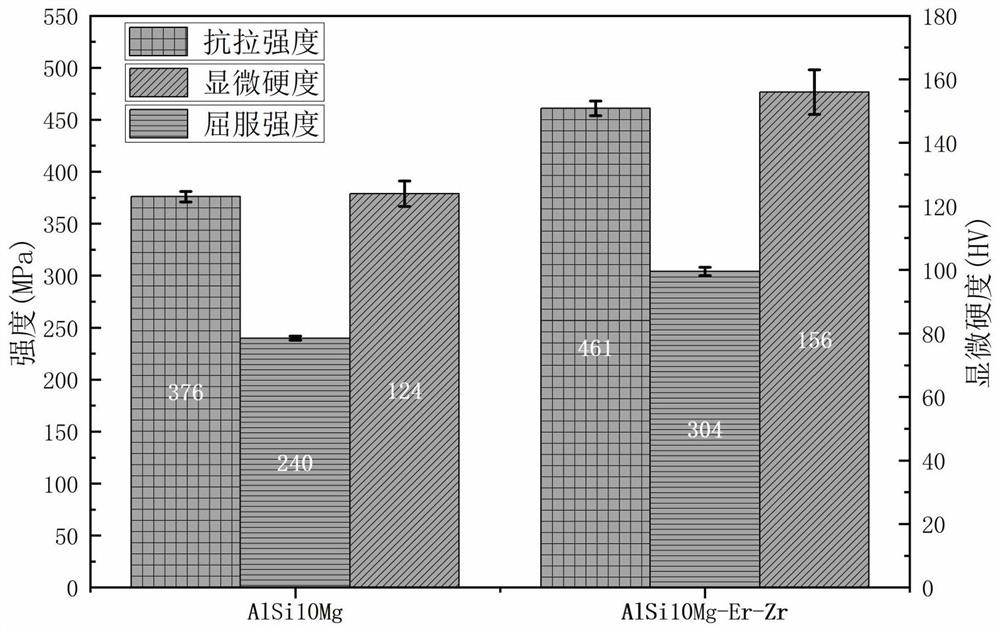

[0050] Using the same preparation process as in Example 1, the results show that the relative density of the Er, Zr composite microalloyed AlSi10Mg alloy tensile specimen after SLM forming of the powder provided in Example 2 can reach 99.07%, without macroscopic cracks and pores , the average microhardness value is 134.6±1HV, the tensile strength is 378±3MPa, and the yield strength is 245±3MPa. Compared with the formed sample without adding Er, Zr (compared with the Er, Zr composite microalloyed AlSi10Mg alloy tensile sample prepared in Example 2, only in the AlSi10Mg powder without adding Er, Zr) the microhardness has improved 8HV, the tensile strength increased by 11MPa, and the yield stre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average grain size | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com