High-strength wallboard, manufacturing method and wall system thereof

A production method and high-strength technology, applied in the direction of walls, building reinforcements, structural elements, etc., can solve the problems of insufficient wind pressure resistance and toughness of wall panels, and achieve the effect of not easy to deform, strong toughness, and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

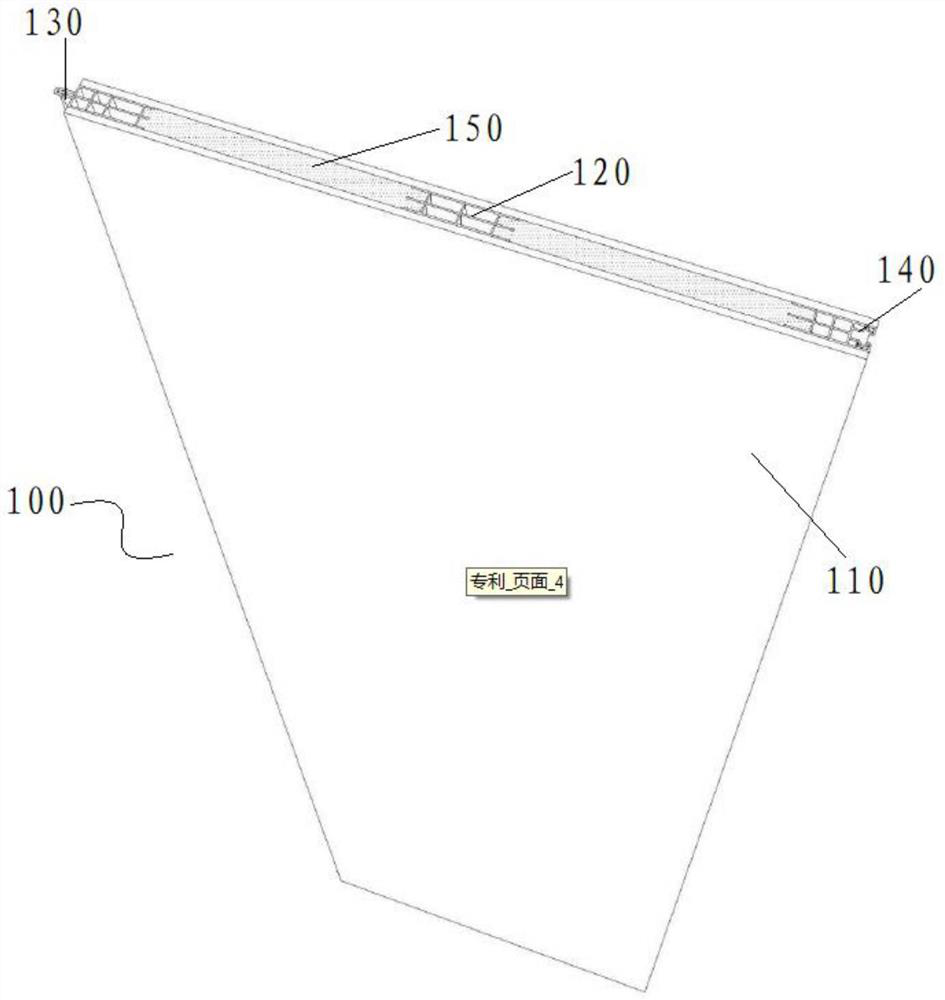

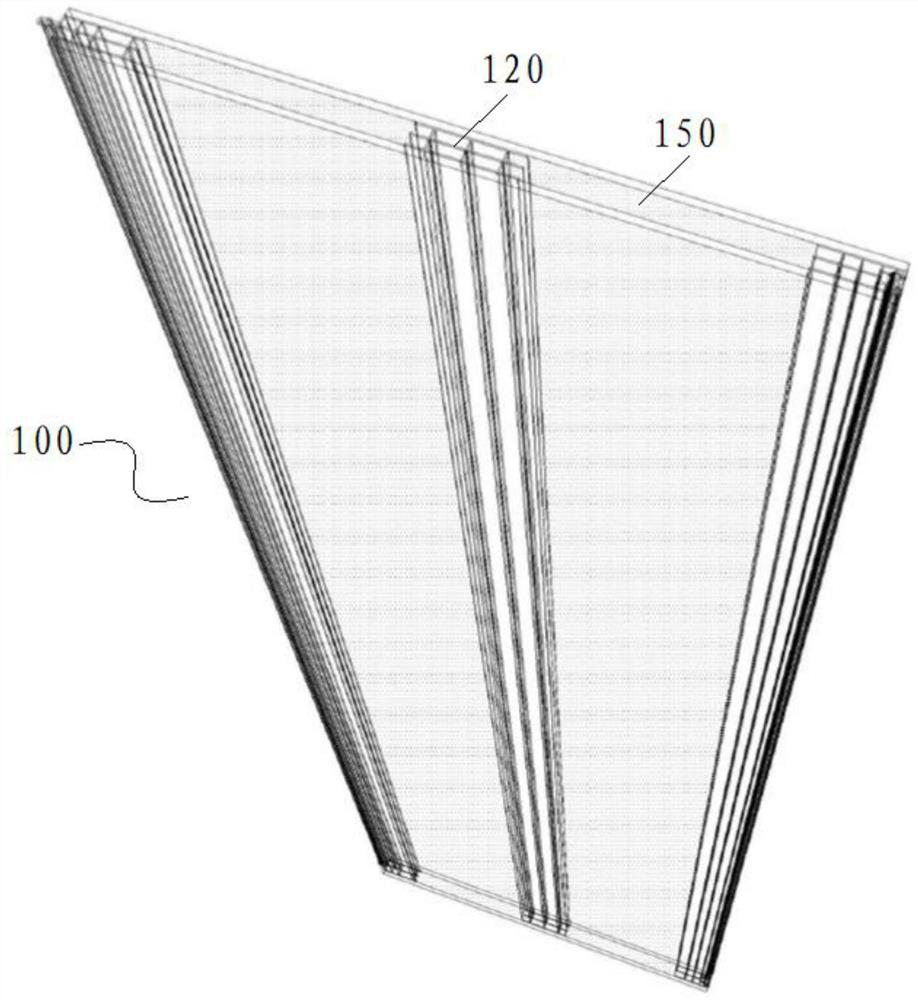

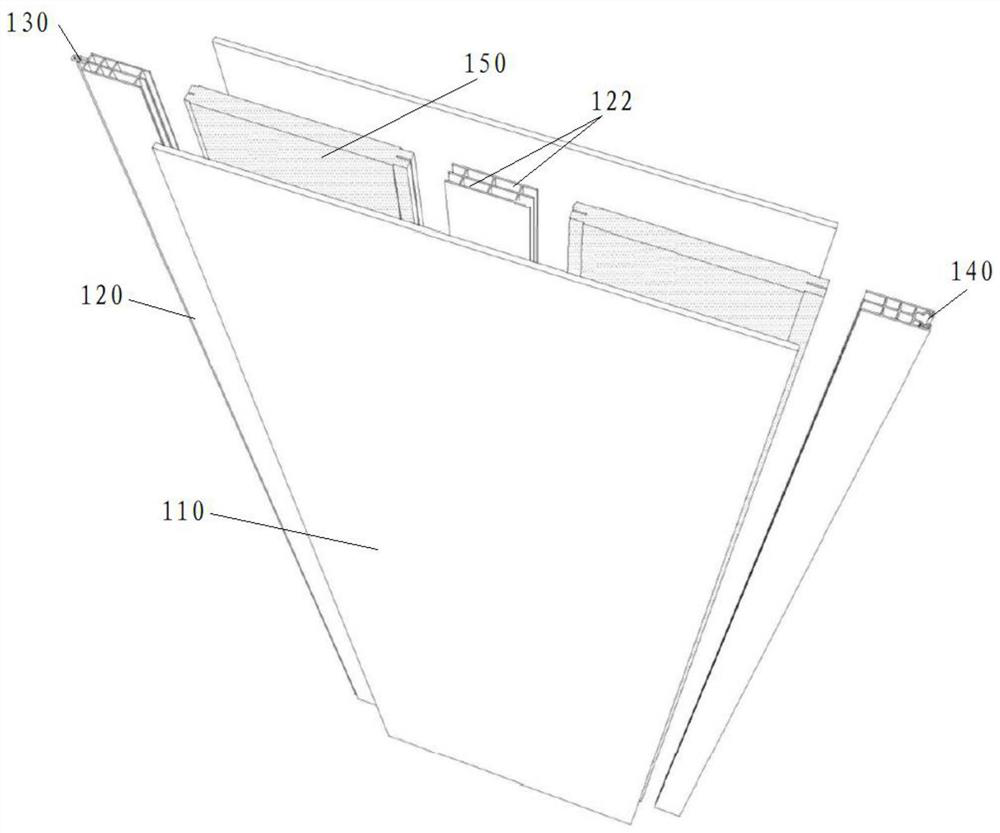

[0059] Figure 1~5 They are respectively the structural schematic diagram, perspective view, exploded view, front view and top view of a high-strength wallboard provided by an embodiment of the present application, such as Figure 1~5 As shown, the wall panel 100 includes two cover panels 110 , several plastic-steel reinforcement flutes 120 and pouring parts 150 .

[0060] The two cover plates 110 are relatively spaced apart, and several plastic-steel reinforced corrugations 120 are spaced between two adjacent cover plates 110, and the plastic-steel reinforced corrugated plates 120 are fixedly connected to the cover plates 110 on both sides, and The plastic-steel reinforced flute 120 includes at least two layers of plastic-steel 122; the pouring part 150 is poured between two adjacent plastic-steel reinforced flutes 120, and integrally formed with the cover plates 110 on both sides. Specifically, both the plastic-steel reinforced flute 120 and the pouring part 150 are in the ...

Embodiment 2

[0078] Based on the same inventive concept as the high-strength wallboard in the foregoing embodiments, the embodiment of the present application also provides a method for manufacturing an enclosure panel for a prefabricated building.

[0079] Described preparation method comprises the steps:

[0080] The plastic-steel reinforced flutes 120 are fixed at intervals between two adjacent cover plates 110, and a gap is formed between the adjacent two plastic-steel reinforced flutes 120;

[0081] Set up pouring holes on the cover plate 110 corresponding to each of the gaps;

[0082] pouring slurry into the corresponding gap through the pouring hole;

[0083] The slurry is integrated with the cover plates 110 on both sides, and is fitted with the plastic-steel reinforced flute 120 at both ends, and solidified and formed to form the plastic-steel reinforced flute filler 150, thereby forming the wallboard 100.

[0084] Further, the material of the slurry is the same as that of the ...

Embodiment 3

[0087] Based on the same inventive concept as the high-strength wallboard in the first embodiment, the embodiment of the present application also provides a high-strength wall system.

[0088] Figure 9 It is a structural schematic diagram of a high-strength wall system provided by an embodiment of the present application, such as Figure 9 As shown, the wall system includes a steel frame 200 , the wall panel 100 and a fixing piece 300 .

[0089] A plurality of wall panels 100 are arranged on the steel frame 200, and two adjacent wall panels 100 are snap-fitted through the male groove 130 and the female groove 140, and the male groove The clamp strip 131 on the 130 is snapped into the slot 141 on the female tongue and groove 140; the inner end of the fixing member 300 runs through the cover plate 110 on the wall panel 100 and the corresponding plastic-steel reinforced flute 120 and and / or pouring parts 150 , and extend into the steel frame 200 to fix the wall panel 100 on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com