Plastic liner composite high-pressure hydrogen storage cylinder and manufacturing method thereof

A technology for composite materials and hydrogen storage bottles, which is applied in the field of high-pressure hydrogen storage bottles made of composite materials with plastic liners, can solve the problems of hidden dangers in the welding process of metal valve seats, poor permeability resistance of plastic non-metallic liners, and unstable quality. Improve hydrogen permeability resistance, low cost, and optimize the effect of winding scheme

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

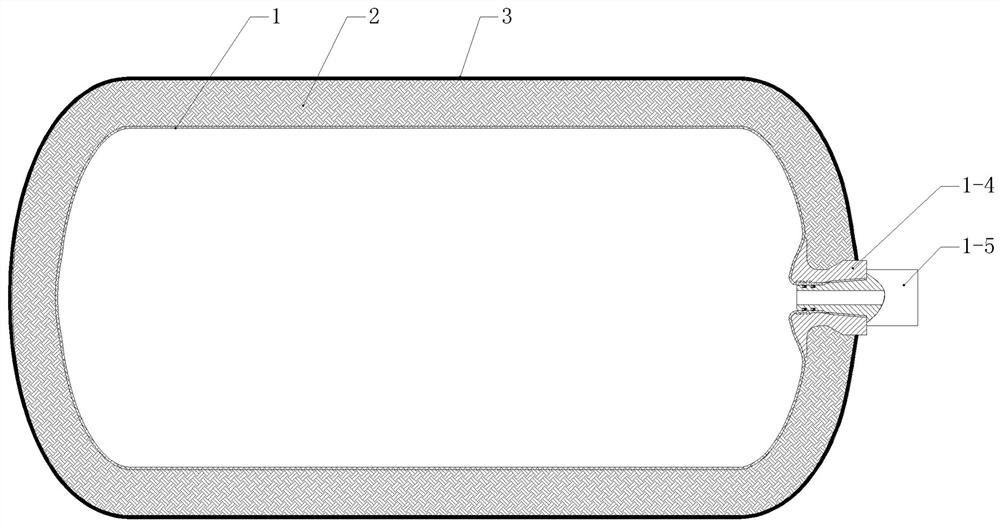

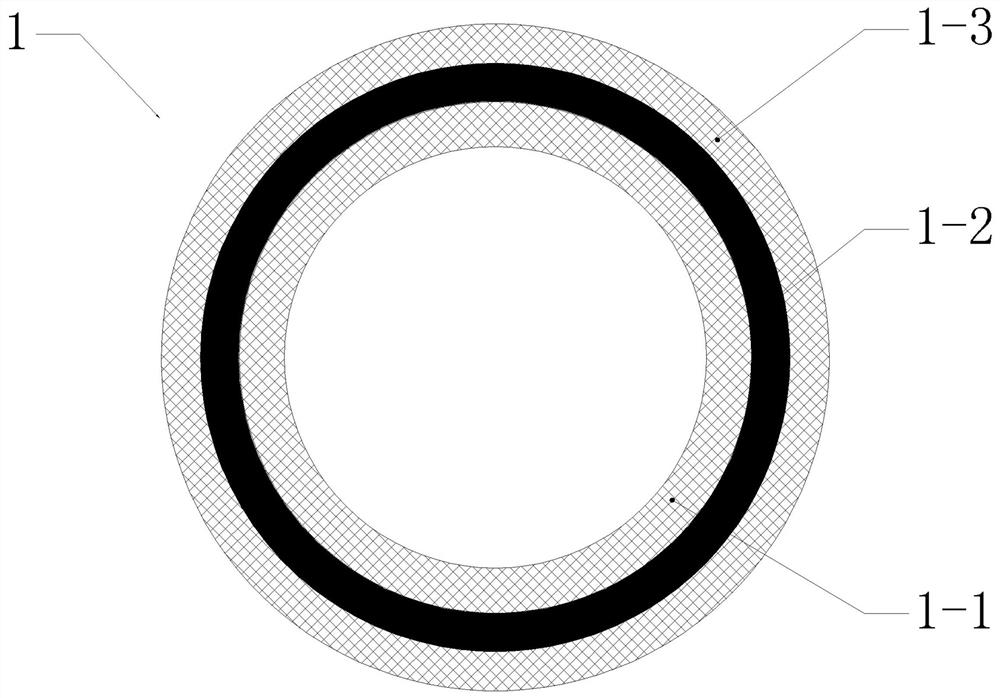

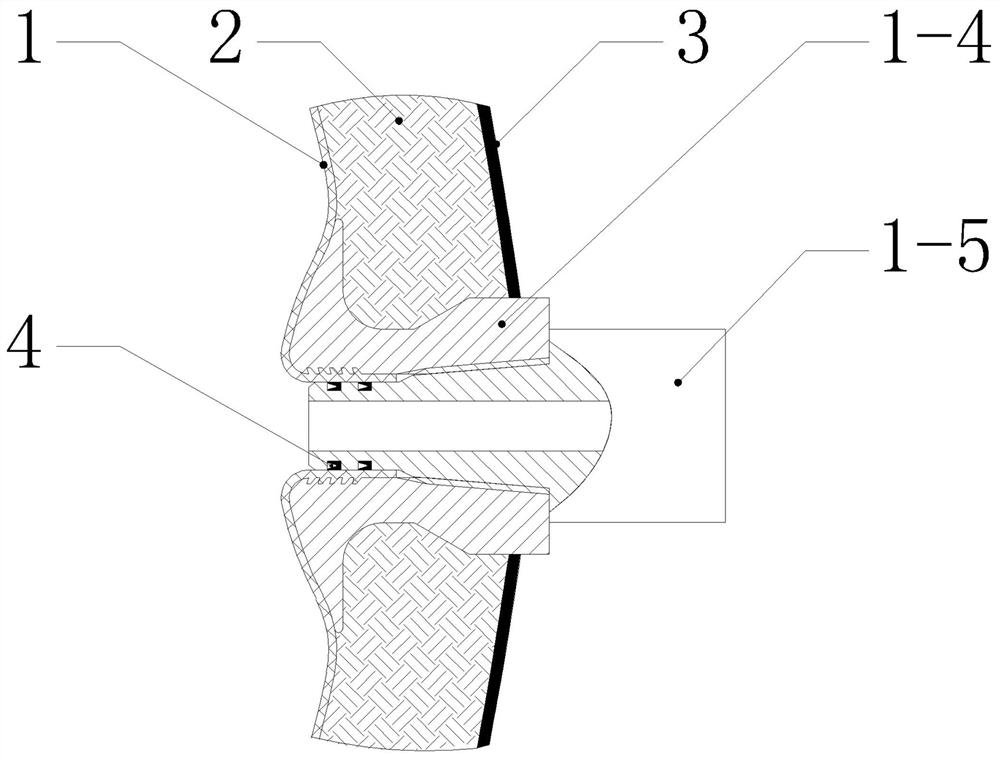

[0027] Example: as attached Figure 1-4 As shown, a plastic liner composite high-pressure hydrogen storage bottle includes a bottle body and a metal bottle mouth assembly. The bottle body includes a plastic liner 1, a winding layer 2 and an outer protective layer 3 connected sequentially from the inside to the outside. The bladder includes a plastic liner inner layer 1-1, a plastic liner isolation layer 1-2, and a plastic liner outer layer 1-3 bonded in sequence from the inside to the outside, and the metal bottle mouth assembly includes an inlaid base 1-4 and a valve seat 1-5. The inlaid base and the plastic liner are fused and bonded together. There is a central connection hole in the center of the inlaid base. The central connection hole of the inlaid base is threaded with the valve seat. Fusion-bonded plastic liner sections form a seal.

[0028] The inner layer of the plastic liner and the outer layer of the plastic liner are preferably HDPE layers. To improve the toughn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com