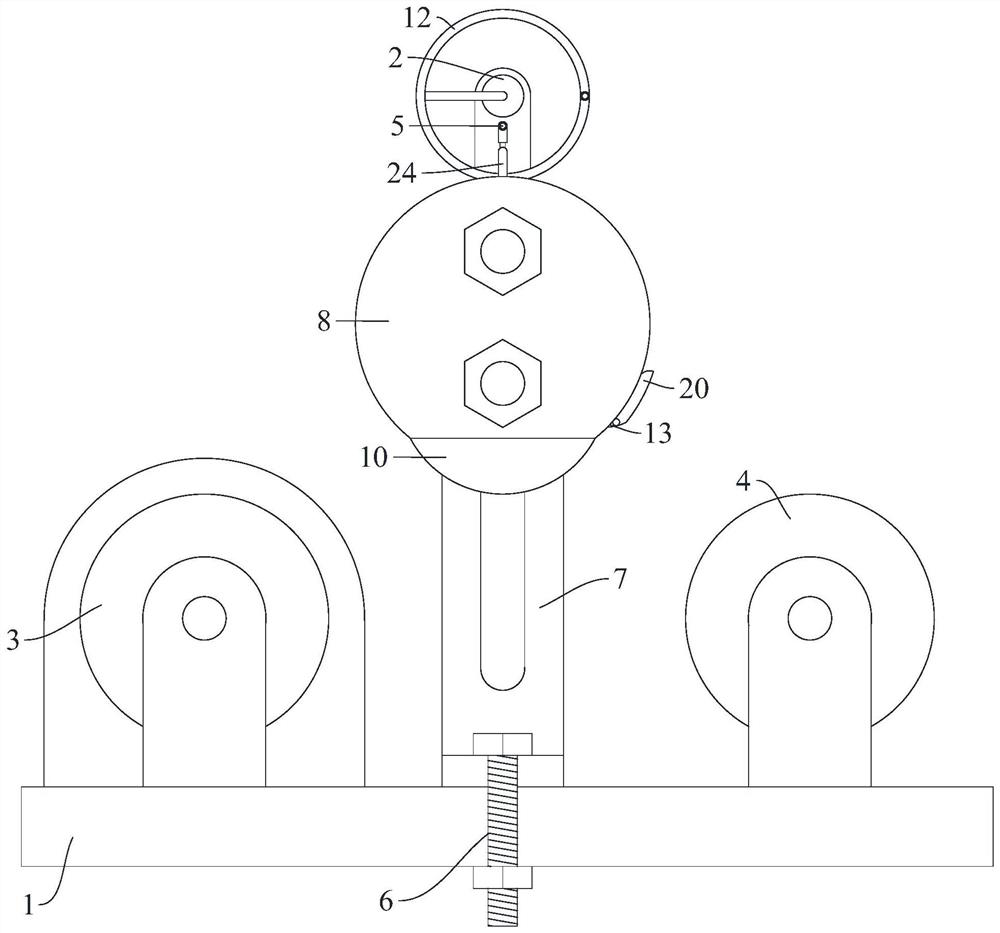

An overhead water cooling device for steel plate production conveyor belt

A technology of water-cooling device and conveyor belt, which is applied in the direction of cleaning device, conveyor, transportation and packaging, etc. It can solve the problems that the surface water cannot be scraped off quickly, the resource recovery rate is not high, and the steel surface is easy to oxidize and rust, etc. The frequency of daily maintenance and the cost of later use, the effect of avoiding stagnant steel and rusting, and improving the recycling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

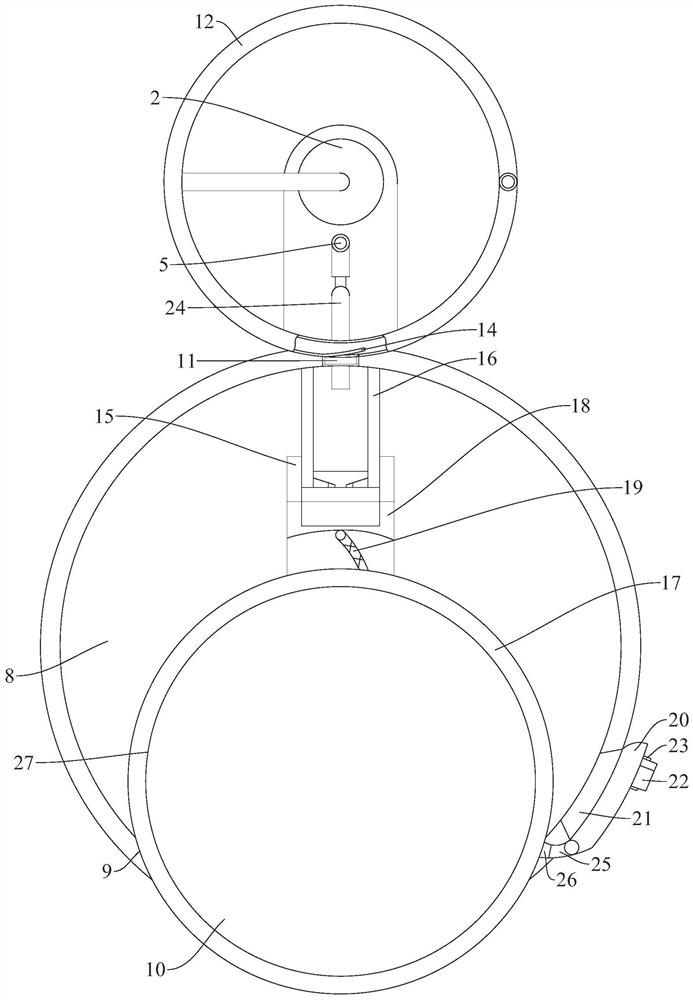

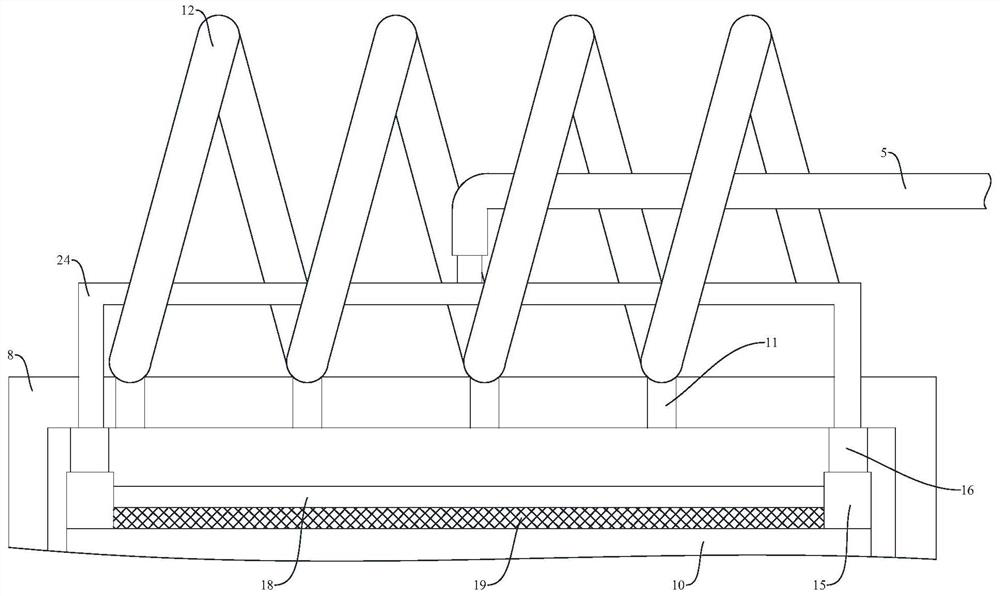

[0024] Embodiment: The electric fan 2 blows to the inside of the metal condensation exhaust pipe 12, and then draws and discharges the water vapor inside the top installation cylinder 8.

[0025] Further, in order to cooperate with the top air extraction, the bottom of the metal condensate exhaust pipe 12 has a downwardly protruding integrated bottom assembly pipe, and the metal condensate exhaust pipe 12 is inserted into the top exhaust through hole 11 and the top installation cylinder through the bottom assembly pipe 8 is connected internally, and the metal condensing exhaust pipe 12 has an arc-shaped surface at the opening of the bottom assembly pipe with an arc-shaped deflector 14. Further, in order to cooperate with the top telescopic guide and water intake, the top gravity guide mechanism includes the installation of internal gravity drainage The top assembly cylinder 15 at the upper end of the cylinder 10, the top guide cylinder 16 welded and fixed on the inner top surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com