Composite abrasive particle of polyacrylamide grafted nano-diamond as well as preparation method and application of composite abrasive particle

A nano-diamond and polyacrylamide technology, which is applied in metal processing equipment, grinding/polishing equipment, polishing compositions containing abrasives, etc., can solve the problem of decreased processing rate in polishing process, decreased workpiece surface quality, and can not meet polishing requirements. and other problems, to achieve the effect of increasing the number of effective abrasive particles, increasing the contact area, and improving the chance of chemical action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The preparation method of the composite abrasive grain of polyacrylamide grafted nano-diamond of the present invention, it comprises the steps:

[0043] (1), pretreated nano-diamond: a certain amount of nano-diamond powder is mixed with 2wt% organic acid, ball milled for 6h, and the metal impurities adsorbed on the surface of nano-diamond are removed by acid treatment to obtain the first mixed solution; then, the first mixed Wash with water to neutrality to obtain well-dispersed pretreated nano-diamonds;

[0044] (2), surface silanization of pretreated nano-diamonds: mix a certain amount of pre-treated nano-diamonds with absolute ethanol, and ultrasonically 1-2h (preferably 0.5h) at room temperature to obtain the second mixed solution; The mixed solution is slowly heated to 80-100°C (preferably 90°C), and the alcohol solution of the silane coupling agent KH570 is added dropwise to obtain the third mixed solution; 9h (preferably 8h) to form silanized nano-diamond partic...

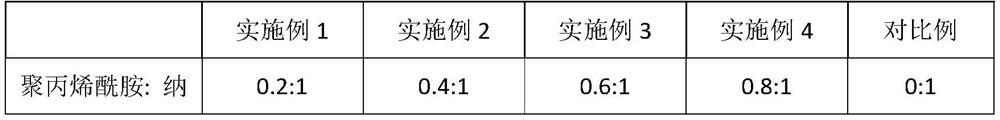

Embodiment 1

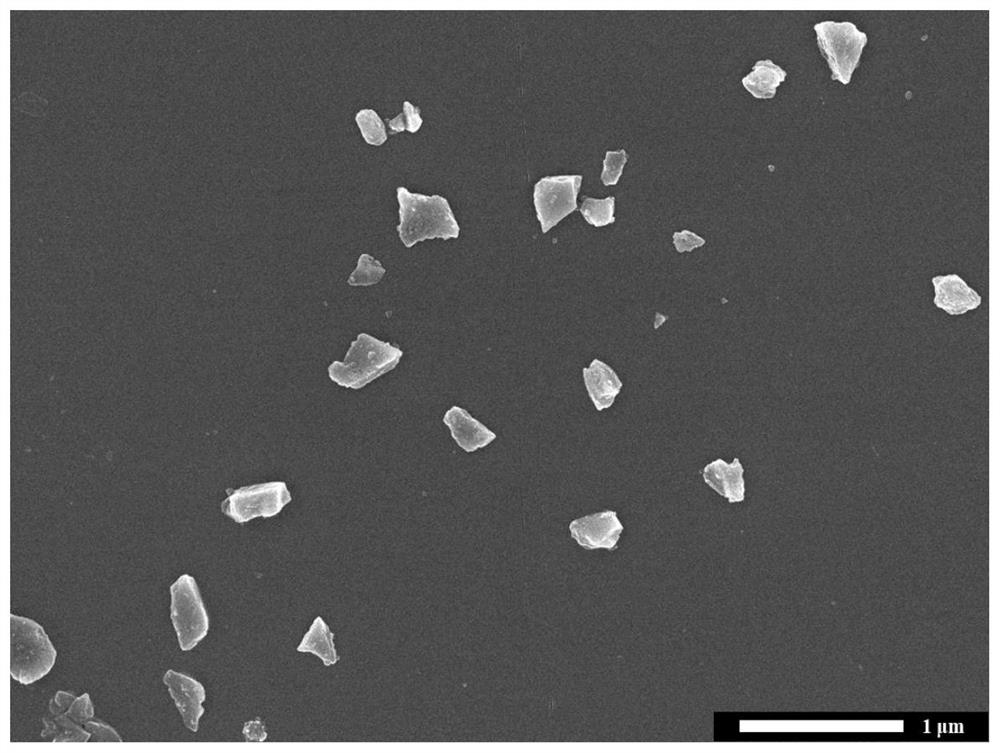

[0057] see figure 1 , the composite abrasive grains of polyacrylamide grafted with nano-diamond in this embodiment, the inner core is nano-diamond, and the polyacrylamide coating layer is formed on the surface of diamond by free radical polymerization through silane coupling agent KH570, wherein, polyacrylamide and nano-diamond The mass ratio of diamond is 0.2:1.

[0058] The preparation method of the composite abrasive grain grafted with polyacrylamide of the present embodiment comprises the following steps:

[0059] (1), pretreated nano-diamond: 10g nano-diamond powder is mixed with 2wt% organic acid (mixed acid of 1wt% citric acid and 1wt% gallic acid), ball milled for 6h, and the metal adsorbed on the surface of nano-diamond is removed by acid treatment Impurities are removed to obtain the first mixed solution; then, the first mixed solution is washed to neutrality to obtain well-dispersed pretreated nano-diamonds.

[0060] (2), surface silanization of pretreated nano-di...

Embodiment 2

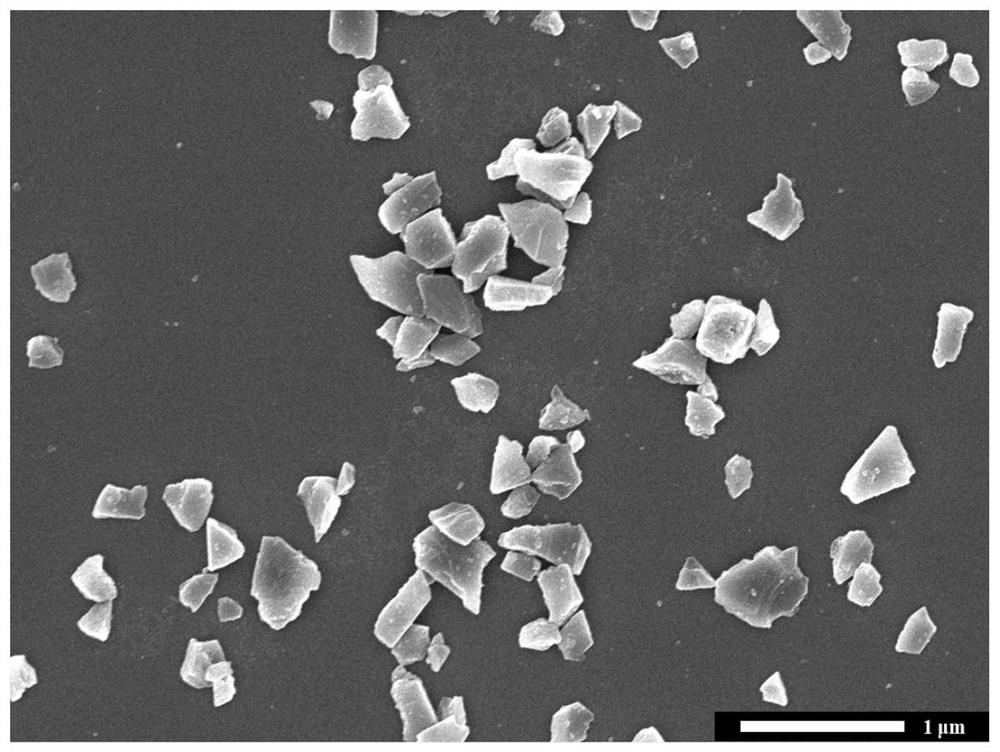

[0064] This embodiment is basically the same as Embodiment 1, and the special features are:

[0065] The composite abrasive grains of polyacrylamide grafted with nano-diamond in this embodiment, the inner core is nano-diamond, and the polyacrylamide coating layer is formed by free radical polymerization on the surface of diamond through silane coupling agent KH570, wherein, polyacrylamide and nano-diamond The mass ratio is 0.4:1.

[0066] In the preparation method of the composite abrasive grain grafted with polyacrylamide of the present embodiment:

[0067] (1), this step is identical with embodiment 1.

[0068] (2), this step is identical with embodiment 1.

[0069] (3) Preparation of composite abrasive grains of polyacrylamide-grafted nano-diamonds: 4 g of silylated nano-diamonds in step (2) were mixed with 100 g of deionized water, and ultrasonically dispersed to form a uniform suspension. Then, under the protection of nitrogen atmosphere, the water bath was heated to 8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com