Network cable processing equipment

A technology for processing equipment and network cables, which is applied to equipment for dismantling/armoring cables, cable installation devices, recycling technology, etc. It can solve the problems of difficult processing, waste of resources, and poor practicability, and improve processing efficiency. , the effect of reducing power loss and improving practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

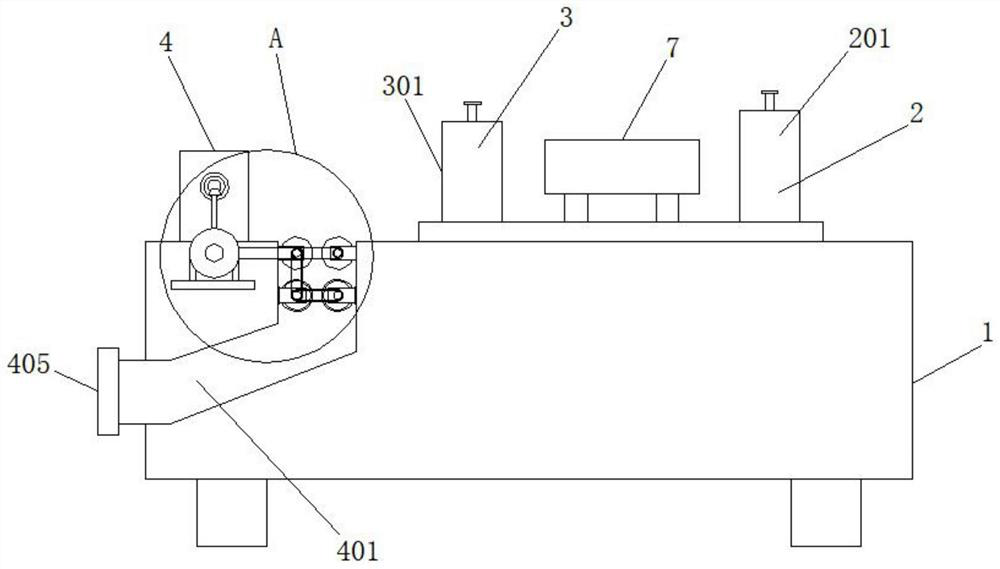

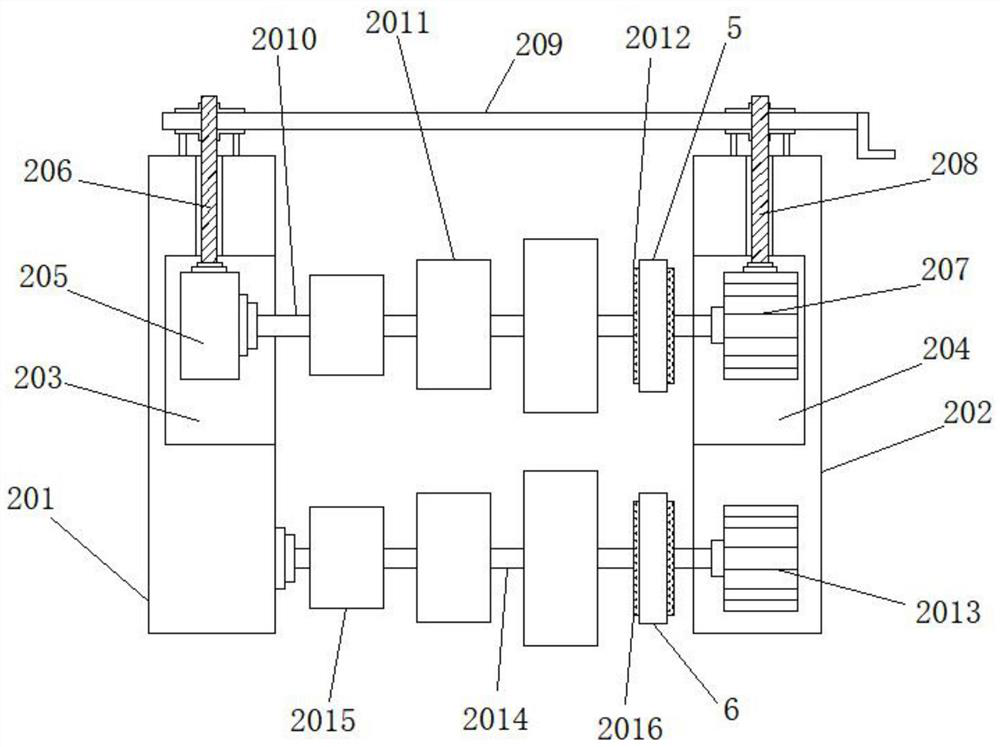

[0026] see Figure 1-7, a network cable processing equipment, including a base 1, the top of the base 1 is sequentially installed with a wire inlet mechanism 2, a peeling mechanism 3 and a recovery mechanism 4, and the wire inlet mechanism 2 includes a No. 1 fixed on the top of the base 1 Support plate 201 and No. 2 support plate 202, and the opposite sides of No. 1 support plate 201 and No. 2 support plate 202 are respectively provided with No. 1 movable groove 203 and No. 2 movable groove 204, and the inside of No. 1 movable groove 203 is slidingly connected with sliding Block 205, and the top of slide block 205 is connected with No. 1 threaded rod 206 through bearing rotation, and the inside of No. 2 movable groove 204 is connected with No. 1 motor 207 slidingly, and the top of No. 1 motor 207 is connected with No. 2 threaded rod 208 through bearing rotation One end of No. 1 threaded rod 206 and one end of No. 2 threaded rod 208 are threadedly connected with No. 3 threaded ...

Embodiment 2

[0031] On the basis of Example 1, please refer to Figure 1-7 :

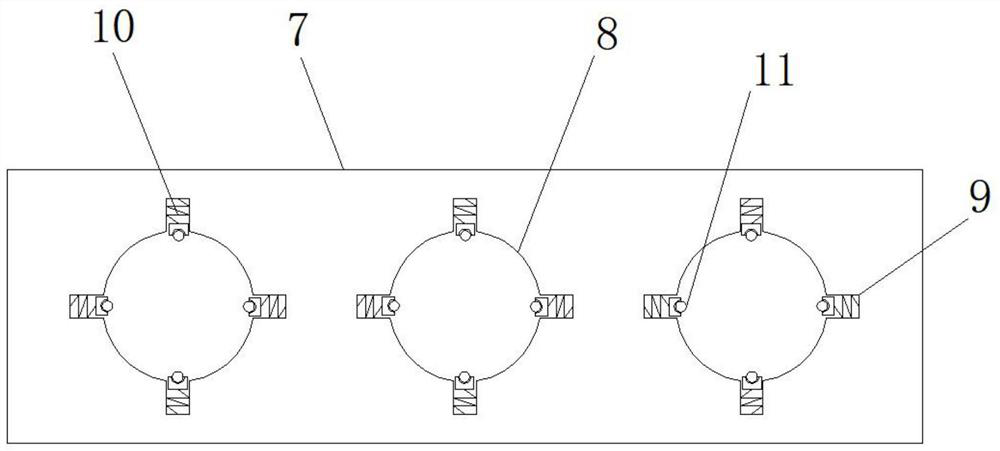

[0032] Concrete, between the wire inlet mechanism 2 and the peeling mechanism 3, a lead plate 7 is horizontally arranged, and the surface of the lead plate 7 is provided with several guide grooves 8, and the inner walls of some guide grooves 8 are all provided with some grooves 9, and the grooves The inside of 9 is fixedly connected with spring 10, and the other end of spring 10 is fixedly connected with pulley 11, and pulley 11 is in contact with the outer wall of network cable, can reduce the friction of network cable and guide groove 8 inside, is convenient to network cable moves.

[0033] Specifically, the pulley 11 forms an elastic stretch structure through the spring 10 and the groove 9, which is convenient for transporting network cables of different sizes.

[0034] In this embodiment, one end of the network cable enters the guide groove 8 on one side of the wire guide plate 7, and under the action of th...

Embodiment 3

[0036] On the basis of Example 1, please refer to Figure 1-7 :

[0037] Specifically, the winding device 406 is composed of a No. 1 base 4061, a No. 2 base 4062, and a winding roller 4063. Both the No. 1 base 4061 and the No. 2 base 4062 are horizontally sleeved with a connecting rod 4064, and the winding roller Both ends of 4063 are fixed with connecting rod 4064 by bolts, the other end of connecting rod 4064 is fixedly connected with No. 1 rotating rod 4065, the top of base 1 is provided with adjustment groove 4066, and the bottom end of No. 1 base 4061 is fixedly connected with adjusting block 4067, one end of the No. 1 rotating rod 4065 is fixedly connected with the No. 1 connecting gear 4068, and the outer wall of the No. 1 connecting gear 4068 is engaged with the No. 2 connecting gear 4069, and one end of the No. 2 connecting gear 4069 is fixedly connected with the No. 2 rotating rod 4610. And the other end of the No. 2 rotating rod 4610 is fixedly connected with the N...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap