Jackfruit cheese sauce and process thereof

A technology of jackfruit cheese sauce and jackfruit is applied in the direction of food ingredients as emulsifiers, food ingredients as thickeners, food ingredients as antimicrobial preservation, etc. problems, to achieve uniform taste and flavor, reduce processing costs, and enhance the effect of umami

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

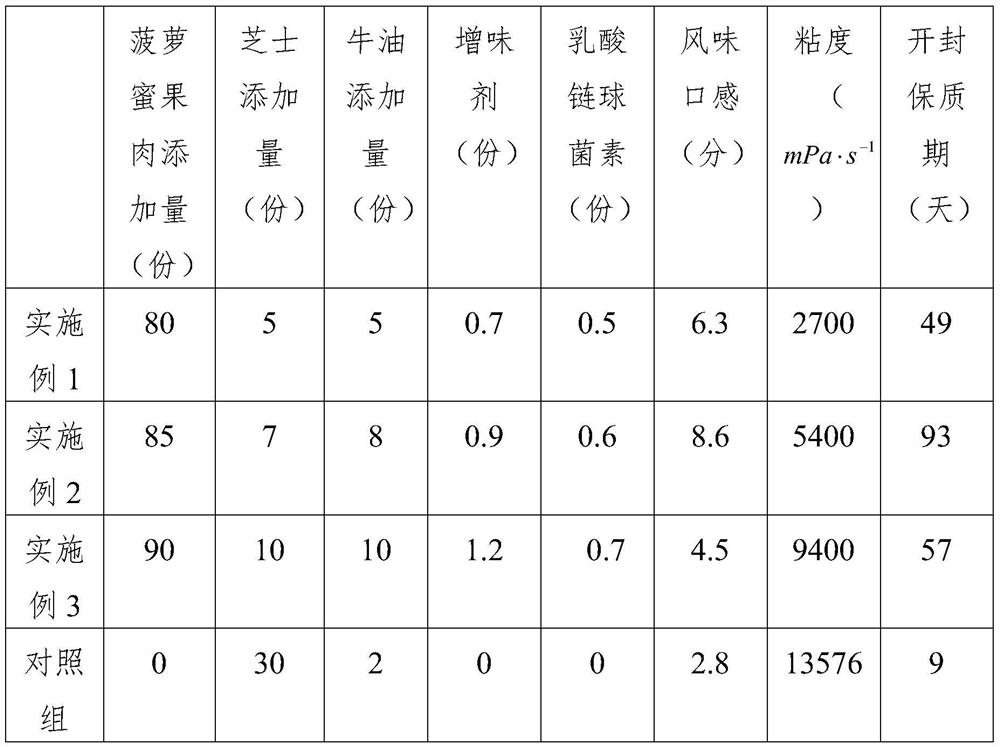

Embodiment 1

[0026] The invention provides a jackfruit cheese sauce. The raw materials used (by parts by weight) include 80-90 parts of jackfruit pulp, 5-10 parts of cheese and 5-10 parts of butter, and the auxiliary materials used (by parts by weight) include 3-7 parts of emulsifier, 3-8 parts of thickener, 2-5 parts of polydextrose, 13-28 parts of skimmed milk powder, 12-26 parts of whey powder, 8-12 parts of margarine, 1.5-3 parts of compound phosphate 13-16 parts of water, 1-2 parts of modified starch, 1.5-2 parts of table salt, 0.5-0.7 parts of edible preservatives, 3-5 parts of white sugar and 0.7-1.2 parts of flavor enhancer.

[0027] And specifically in this embodiment: the raw materials used (in parts by weight) include 80 parts of jackfruit pulp, 5 parts of cheese and 5 parts of butter, and the auxiliary materials used (in parts by weight) include 3 parts of emulsifier, thickener 3 parts of preservatives, 2 parts of polydextrose, 13 parts of skimmed milk powder, 12 parts of whey ...

Embodiment 2

[0036]The invention provides a jackfruit cheese sauce. The raw materials used (by parts by weight) include 80-90 parts of jackfruit pulp, 5-10 parts of cheese and 5-10 parts of butter, and the auxiliary materials used (by parts by weight) include 3-7 parts of emulsifier, 3-8 parts of thickener, 2-5 parts of polydextrose, 13-28 parts of skimmed milk powder, 12-26 parts of whey powder, 8-12 parts of margarine, 1.5-3 parts of compound phosphate 13-16 parts of water, 1-2 parts of modified starch, 1.5-2 parts of table salt, 0.5-0.7 parts of edible preservatives, 3-5 parts of white sugar and 0.7-1.2 parts of flavor enhancer.

[0037] And specifically in this embodiment: the raw materials used (in parts by weight) include 85 parts of jackfruit pulp, 7 parts of cheese and 8 parts of butter, and the auxiliary materials used (in parts by weight) include 5 parts of emulsifier, thickener 6 parts of preservatives, 3.5 parts of polydextrose, 20 parts of skimmed milk powder, 19 parts of whey...

Embodiment 3

[0046] The invention provides a jackfruit cheese sauce. The raw materials used (by parts by weight) include 80-90 parts of jackfruit pulp, 5-10 parts of cheese and 5-10 parts of butter, and the auxiliary materials used (by parts by weight) include 3-7 parts of emulsifier, 3-8 parts of thickener, 2-5 parts of polydextrose, 13-28 parts of skimmed milk powder, 12-26 parts of whey powder, 8-12 parts of margarine, 1.5-3 parts of compound phosphate 13-16 parts of water, 1-2 parts of modified starch, 1.5-2 parts of table salt, 0.5-0.7 parts of edible preservatives, 3-5 parts of white sugar and 0.7-1.2 parts of flavor enhancer.

[0047] And specifically in this embodiment: the raw materials used (in parts by weight) include 90 parts of jackfruit pulp, 10 parts of cheese and 10 parts of butter, and the auxiliary materials used (in parts by weight) include 7 parts of emulsifier, thickener 8 parts of agent, 5 parts of polydextrose, 28 parts of skimmed milk powder, 26 parts of whey powder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com