Method and device for welding copper components

A welding method and technology of a welding device, which are applied in the field of copper component welding methods and devices, can solve the problems of inability to meet the requirements of high-dimensional precision welded components, the inability to effectively control the weld structure and matrix consumption, etc., and achieve easy curing welding parameters, Good universality, high-precision solderless soldering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

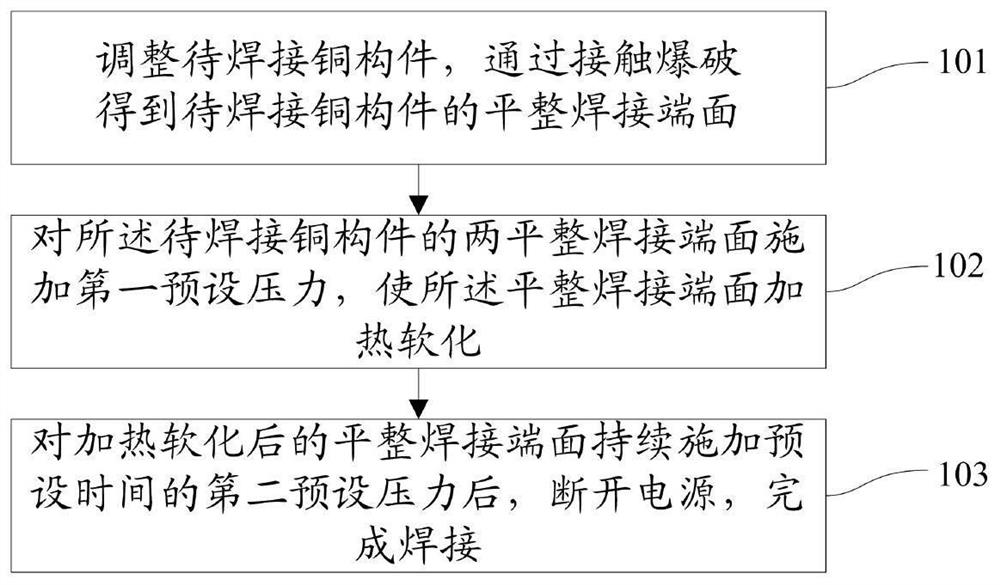

[0032] This embodiment provides a copper component welding method, such as figure 1 shown, including:

[0033] Step 101: Adjust the copper component to be welded so that the two welding end surfaces of the copper component to be welded are in contact, and connect the two welding end surfaces of the copper component to be welded to a power source respectively, so that the two welding end surfaces of the copper component to be welded Produce contact blasting between, obtain the smooth welding end face of described copper component to be welded;

[0034] Step 102: applying a first preset pressure to the two flat welding end surfaces of the copper component to be welded to heat and soften the flat welding end surfaces;

[0035] Step 103: After applying a second preset pressure for a preset time to the flat welded end surface after heating and softening, disconnect the power supply to complete welding; the second preset pressure is greater than the first preset pressure.

[0036]...

Embodiment 2

[0059] As another embodiment of the present invention, such as Figure 5 As shown, a copper member welding device is also provided for realizing the welding method in Embodiment 1, the device comprising:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com