Metallurgy-based solid waste reinforcing material and preparation method thereof

A technology for reinforcing materials and minerals, applied in the field of metallurgical-based solid waste reinforcement materials and preparation, can solve problems such as the reuse of environmental pollution waste, and achieve the effects of reducing carbon emissions, improving durability, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

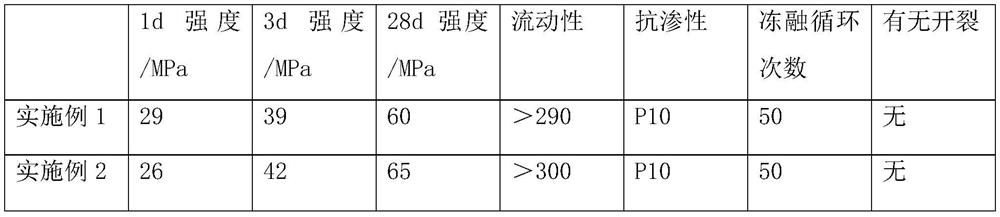

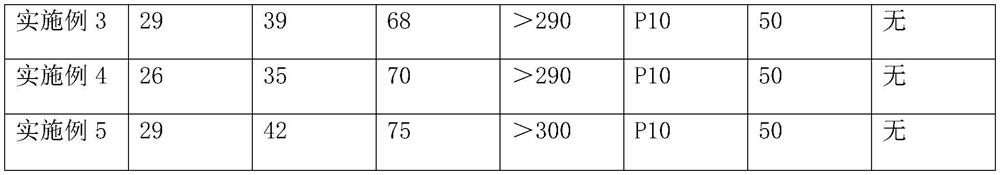

Examples

Embodiment approach

[0022] As a specific embodiment of the metallurgical-based solid waste reinforcement material provided by the present invention, the cementing and solidifying components include: 30%-50% Portland cement clinker and molten iron desulfurization slag powder, 50%-60% blast furnace Slag powder, 5%-6% iron tailings powder, 10%-15% converter steel slag and fly ash mixture; particle size control of each component: Portland cement clinker 3500m 2 / kg-4500m 2 / kg, hot metal desulfurization slag powder 550m 2 / kg-700m 2 / kg, blast furnace slag powder 550m 2 / kg-650m 2 / kg, converter steel slag 500m 2 / kg-600m 2 / kg, fly ash 400m 2 / kg -500m 2 / kg, iron tailings powder 400m 2 / kg-500m 2 / kg.

[0023] In this embodiment, industrial solid waste desulfurization gypsum, blast furnace slag powder, iron tailings powder, steel slag and fly ash are all solid waste materials, accounting for more than half of the cementitious materials. Through the application of a large number of solid w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com