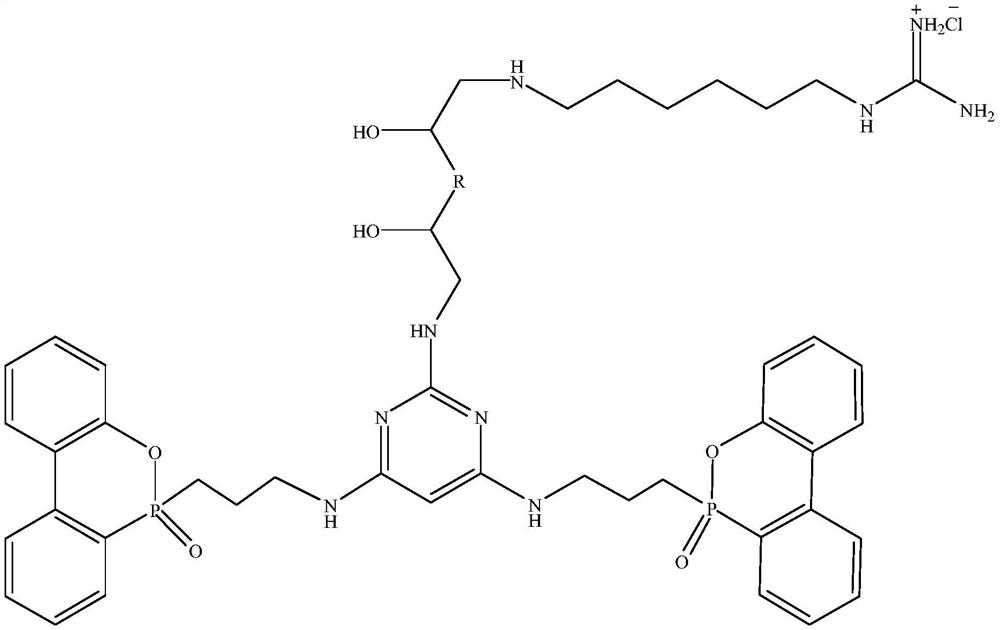

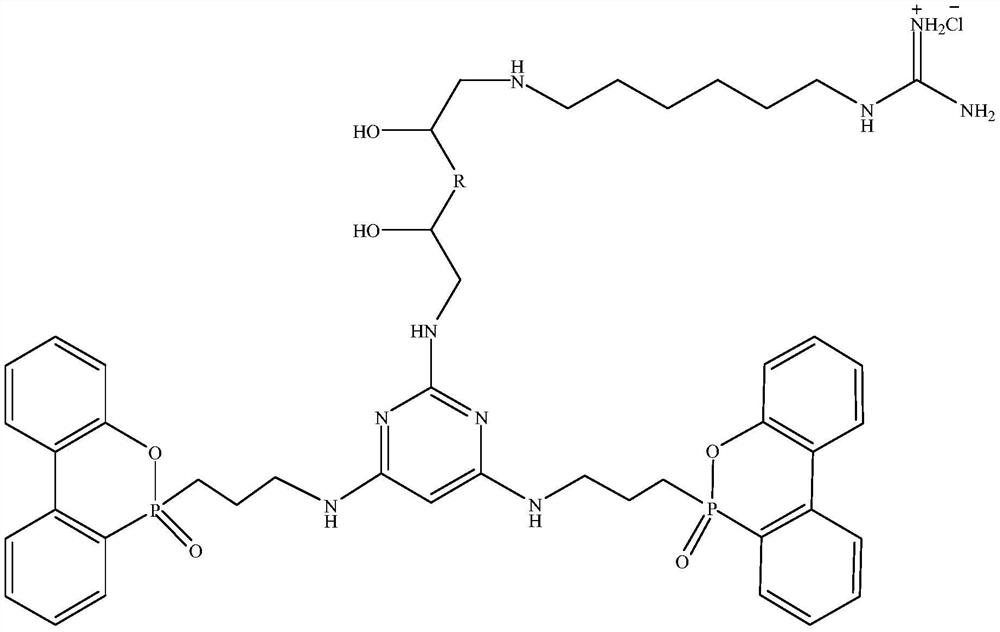

Novel organophosphorus flame retardant and preparation method thereof

An organophosphorus and flame retardant technology, applied in the field of flame retardants, can solve the problems of insignificant effect, low operation efficiency, scarcity of flame retardants, etc., and achieve excellent antibacterial durability, great application prospects, and excellent synergistic flame retardancy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

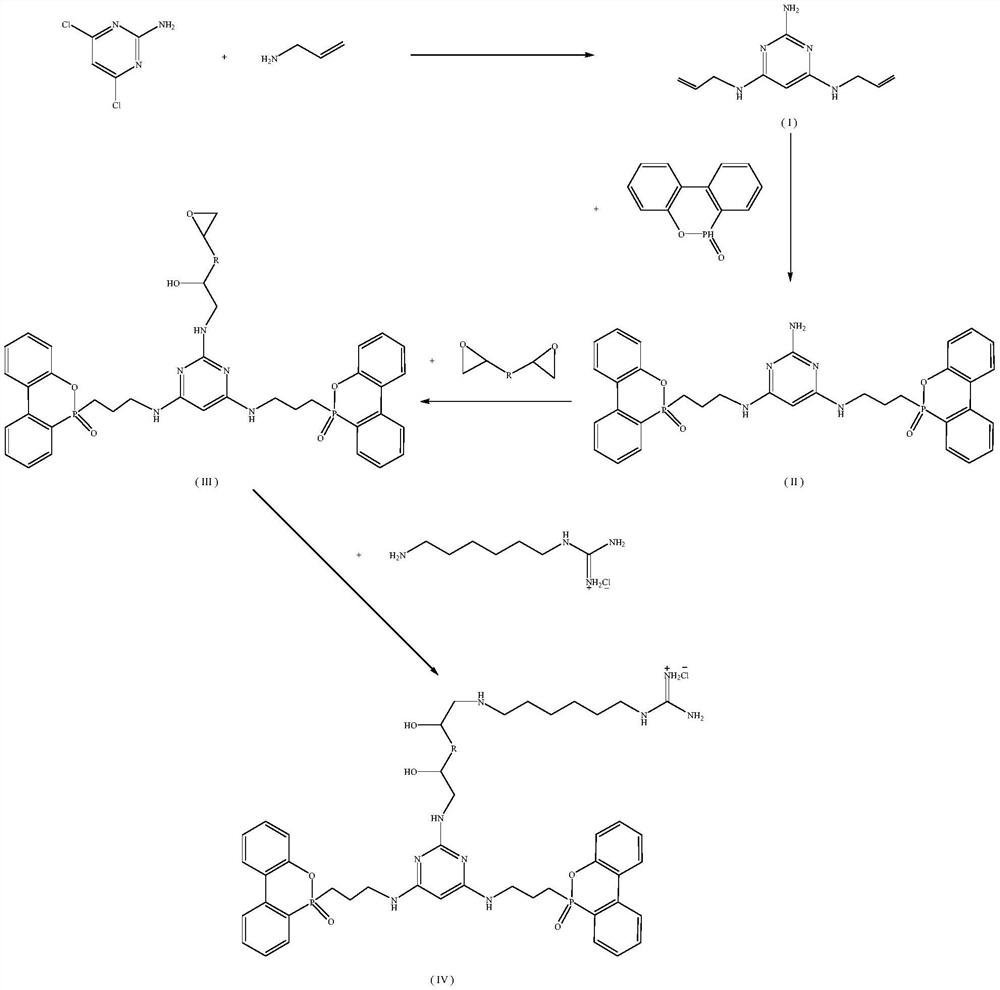

[0034] Embodiment 1: A kind of preparation method of novel organophosphorus flame retardant comprises the following steps:

[0035] (1) Add 1 mol of 2-amino-4,6-dichloropyrimidine, 2 mol of allylamine, and 4 mol of triethylamine into a flask containing a mixed solvent of 30 mol of hexane and ethyl acetate (volume ratio 1 / 1) , stirring at room temperature for 24h, after the reaction, add 40mol deionized water to the mixture, separate the liquid, take the organic phase, distill under reduced pressure, and dry in vacuo to obtain the intermediate product I;

[0036] The infrared data of the intermediate product I are as follows: 3121cm -1 : -NH- exists; 3342cm -1 :-NH 2 Spike exists; 1580cm -1 、1490cm -1 、1440cm -1 : presence of pyrimidine ring; 1611cm -1 :-C=C-exists; 706cm -1 :-C-Cl disappears.

[0037] (2) Dissolve 1mol I and 1.2mol DOPO in 50mol 1,4-dioxane and add to the flask, then add 1wt% AIBN and put it in the flask, put it in an oil bath at 80°C for 8h, after the...

Embodiment 2

[0044] Embodiment 2: A kind of preparation method of novel organophosphorus flame retardant comprises the following steps:

[0045] (1) Add 1mol 2-amino-4,6-dichloropyrimidine, 2mol allylamine, and 4mol triethylamine into a flask containing 30mol hexane and ethyl acetate mixed solvent (volume ratio 2 / 1) , stirred at room temperature for 20 h, after the reaction was completed, 40 mol of deionized water was added to the mixture, the liquid was separated, and the organic phase was taken, distilled under reduced pressure, and dried in vacuo to obtain the intermediate product I;

[0046] The infrared data of the intermediate product I are as follows: 3118cm -1 : -NH- exists; 3340cm -1 :-NH 2 Spikes present; 1575cm -1 、1488cm -1 、1439cm -1 : presence of pyrimidine ring; 1610cm -1 :-C=C-exists; 705cm -1 :-C-Cl disappears.

[0047] (2) Dissolve 1 mol I and 1 mol DOPO in 50 mol 1,4-dioxane and add to the flask, then add 2wt% AIBN and put it in the flask, and put it in an oil ba...

Embodiment 3

[0054] Embodiment 3: A kind of preparation method of novel organophosphorus flame retardant comprises the following steps:

[0055] (1) Add 1mol 2-amino-4,6-dichloropyrimidine, 2mol allylamine, and 4mol triethylamine into a flask containing 30mol hexane and ethyl acetate mixed solvent (volume ratio 1 / 2) , stirring at room temperature for 21h, after the reaction, add 40mol deionized water to the mixture, separate the liquid, take the organic phase, distill under reduced pressure, and dry in vacuo to obtain the intermediate product I;

[0056] The infrared data of intermediate product I are as follows: 3120cm -1 : -NH- exists; 3340cm -1 :-NH 2 Spike exists; 1580cm -1 、1490cm -1 、1440cm -1 : presence of pyrimidine ring; 1610cm -1 :-C=C-exists; 706cm -1 :-C-Cl disappears.

[0057] (2) Dissolve 1mol I, 1.1mol DOPO in 50mol 1,4-dioxane and add to the flask, then add 1.5wt% AIBN and put it in the flask, put it in an oil bath at 75°C for 10h, after the reaction, distill under ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com