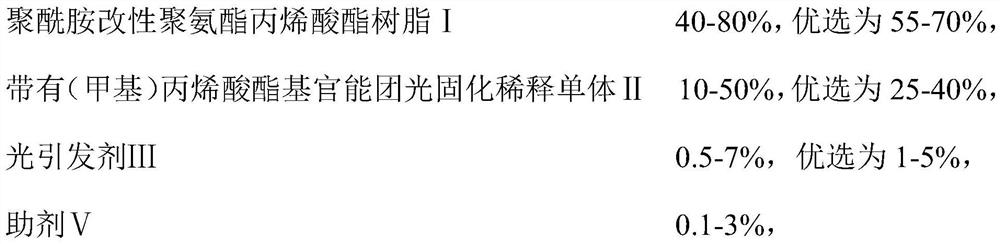

3D printing soft elastic photosensitive resin composition and preparation method thereof

A photosensitive resin and 3D printing technology, which is applied in the field of 3D printing materials, can solve the problems that the mechanical properties cannot meet the market demand, and achieve the effects of good tactile effect, good compatibility and high printing success rate of samples

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

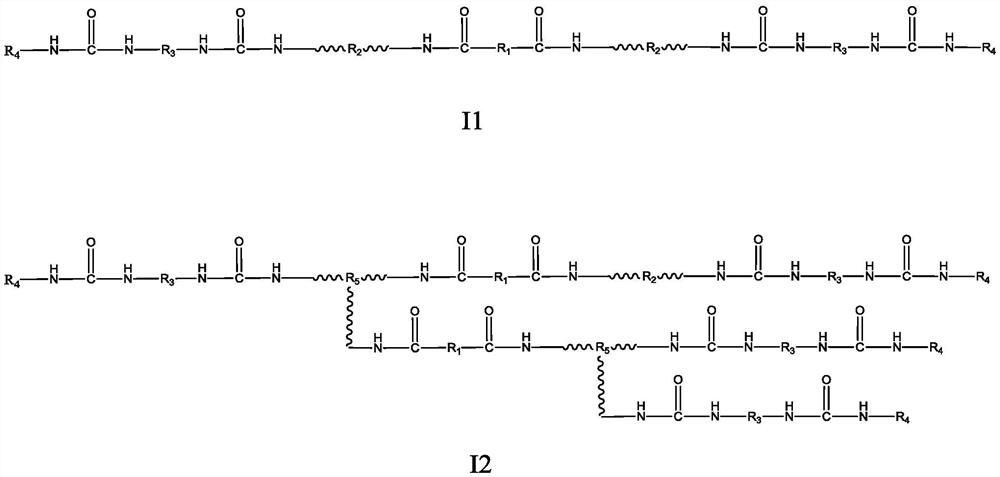

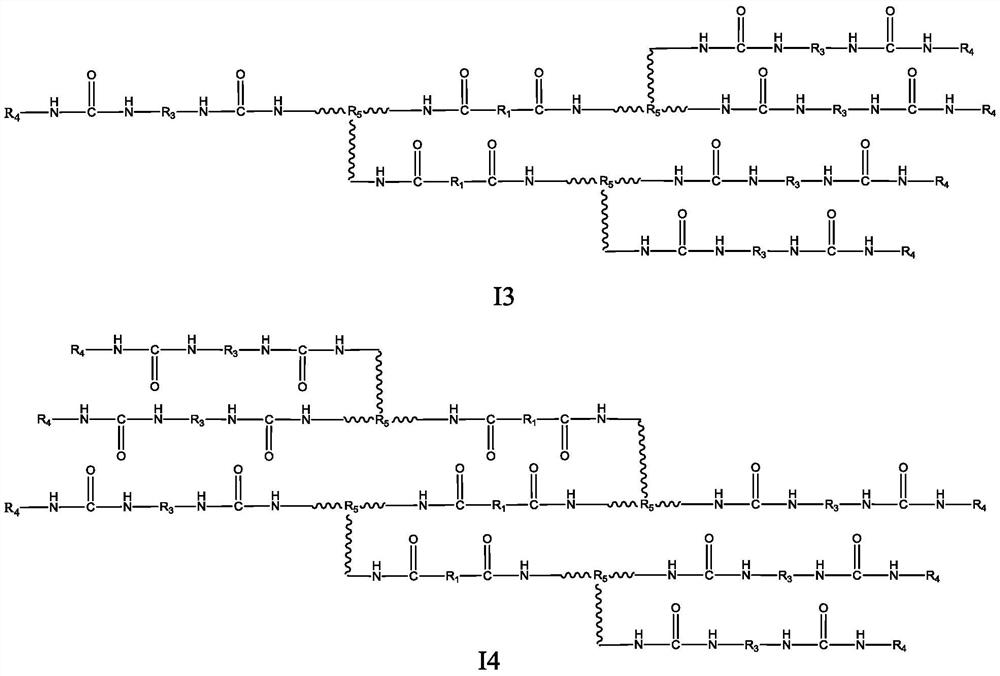

[0080] Polyamide-modified urethane acrylate resin I-1 was prepared.

[0081] 500ml of DMF was added to the reaction flask equipped with a stirring device, a temperature control device and a condensing device, then 200g of amino polyether (D2000) and 4.5g of oxalic acid were added, an inert protective gas was introduced, and the reaction was carried out at 200°C for 8 hours. After the acid value was 0, the temperature was lowered to 70°C, 22.23g IPDI was added to react for 1h, the temperature was controlled to 60°C and 18.5g tert-butylaminoethyl methacrylate was added to react for 1h, and the prepolymerization was measured by n-butylamine titration method. The NCO content of the substance was 0.03%, the reaction was stopped, the material was transferred to a rotary evaporator, and the DMF solvent was evaporated to obtain the polyamide-modified polyurethane acrylate resin I-1.

Embodiment 2

[0083] Polyamide-modified urethane acrylate resin I-2 was prepared.

[0084] 500ml of DMF was added to the reaction flask equipped with a stirring device, a temperature control device and a condensing device, then 300g of aminopolyether (D2000) and 4.5g of oxalic acid were added, an inert protective gas was introduced, and the reaction was conducted at 240°C for 4 hours. After the acid value was 0, the temperature was lowered to 100°C, 44.46g IPDI was added to react for 3h, the temperature was controlled to 70°C and 37g tert-butylaminoethyl methacrylate was added to react for 1h, and the prepolymer was measured by n-butylamine titration method. The NCO content was 0.019%, the reaction was stopped, the material was transferred to a rotary evaporator, and the DMF solvent was evaporated to obtain a polyamide-modified polyurethane acrylate resin I-2.

Embodiment 3

[0086] Preparation of polyamide-modified urethane acrylate resin I-3.

[0087] 500ml of DMF was added to the reaction flask equipped with a stirring device, a temperature control device and a condensing device, then 150g of amino polyether (D2000) and 4.5g of oxalic acid were added, an inert protective gas was introduced, and the reaction was carried out at 220°C for 6 hours. After the acid value was 0, the temperature was lowered to 70°C, 11.12g IPDI was added to react for 2h, the temperature was controlled to 80°C, and 9.25g tert-butylaminoethyl methacrylate was added to react for 1h, and the prepolymerization was measured by n-butylamine titration method. The NCO content of the substance was 0.015%, the reaction was stopped, the material was transferred to a rotary evaporator, and the DMF solvent was evaporated to obtain the polyamide-modified polyurethane acrylate resin I-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com