Volatile organic compound detection quality control device and method

A volatile organic compound and quality control technology, which is applied in measuring devices, analyzing gas mixtures, instruments, etc., to achieve the effects of reducing pipeline retention loss, avoiding water vapor condensation, and improving the efficiency of zero division

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

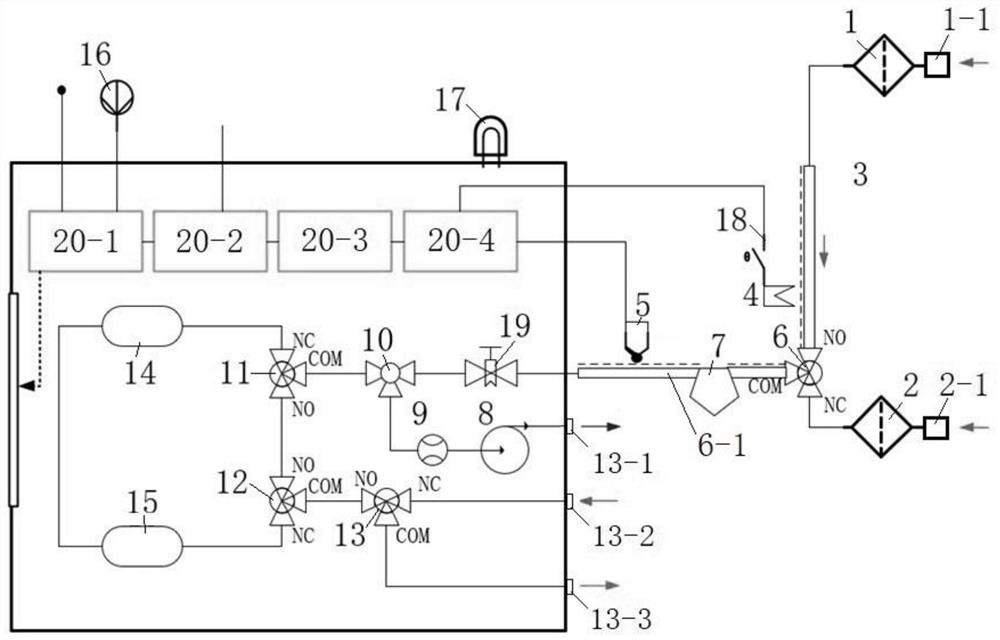

[0040] like figure 1 As shown, a volatile organic compound detection quality control device provided by the present invention includes an outdoor air PTFE filter 1 connected with the outdoor air inlet 1-1, an indoor air filter connected with the indoor air inlet 2-1 Gas PTFE filter 2, indoor and outdoor sampling electromagnetic switching valve 6 connected with outdoor gas PTFE filter 1 and indoor gas PTFE filter 2, outdoor gas PTFE filter 1 and indoor and outdoor sampling electromagnetic switching valve 6 Connected through the outdoor sampling tube 3, the electromagnetic switching valve 6 is connected with the drainage tee 10 provided in the quality control device 20 through the sampling tube 6-1, and the quality control device 20 also includes a flow controller 9, a first catalytic zero Switching valve 11, second catalytic zero-dividing switching valve 12, drainage pump 8, calibration gas selection valve 13, platinum cotton catalytic tube furnace 14, drying molecular sieve 15...

Embodiment 2

[0052] The present invention also provides a quality control method for detecting volatile organic compounds using the device provided in Example 1, comprising the following steps:

[0053] S1: Collect outdoor ambient air: turn on the drainage pump 8, control the preset flow rate through the flow controller 9, the outdoor air to be collected enters the outdoor sampling pipe 3 through the outdoor PTFE filter 1, and passes through the normally open end of the electromagnetic switching valve 6 After entering the water vapor separator 7 and directly passing through the negative pressure sensor 19, it enters the drainage tee 10, the flow controller 9 and the drainage pump 8 to complete the external air drainage function. At this time, another sample gas with a small flow rate passes through the drainage tee 10 and another One end enters the NO-COM end of the second catalytic de-zero switching valve 12 through the COM-NO end of the first catalytic de-zero switching valve 11, and then...

Embodiment 3

[0057] On the basis of Embodiment 2, the present invention also has the following steps before the operation of the S1 step and the S2 step:

[0058] Close the drainage pump 8, open the NC-COM end of the calibration gas selector valve 13, enter the S1 step to collect outdoor gas samples through the single calibration gas inlet 13-2 for 15 minutes, and then enter the S1 step to collect outdoor gas samples. A single-concentration calibration gas is preset to verify the span accuracy of the analyzer, and the span calibration gas verification combined with daily zero-gas background verification can ensure that the analyzer is in a quality control state.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com