Industrial cooking machine control system and method

A technology of control system and control method, applied in the direction of control/regulation system, temperature control, non-electric variable control, etc., can solve the problems of high energy consumption and low intelligence, achieve energy saving, increase accuracy and rapidity , to ensure the effect of flexibility and intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

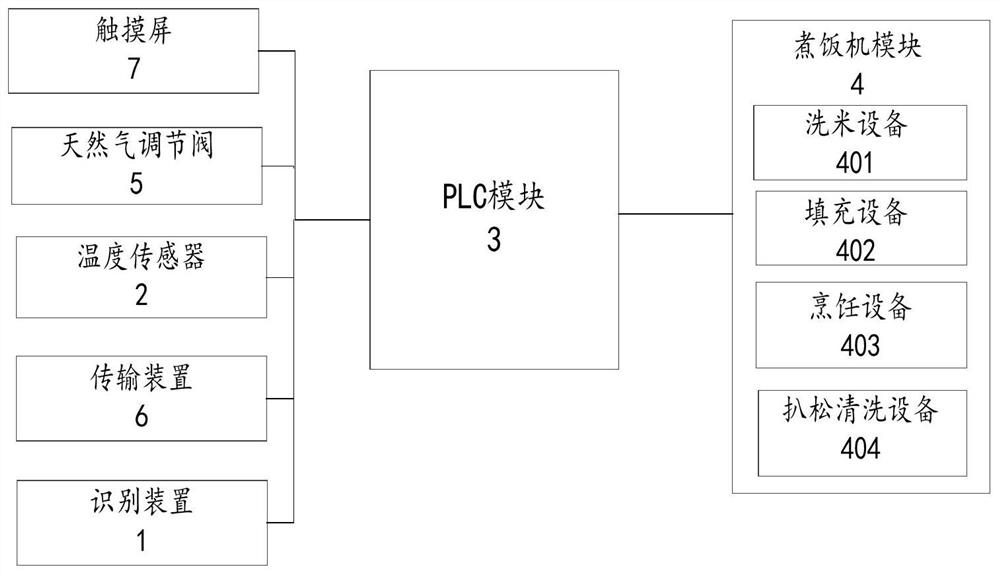

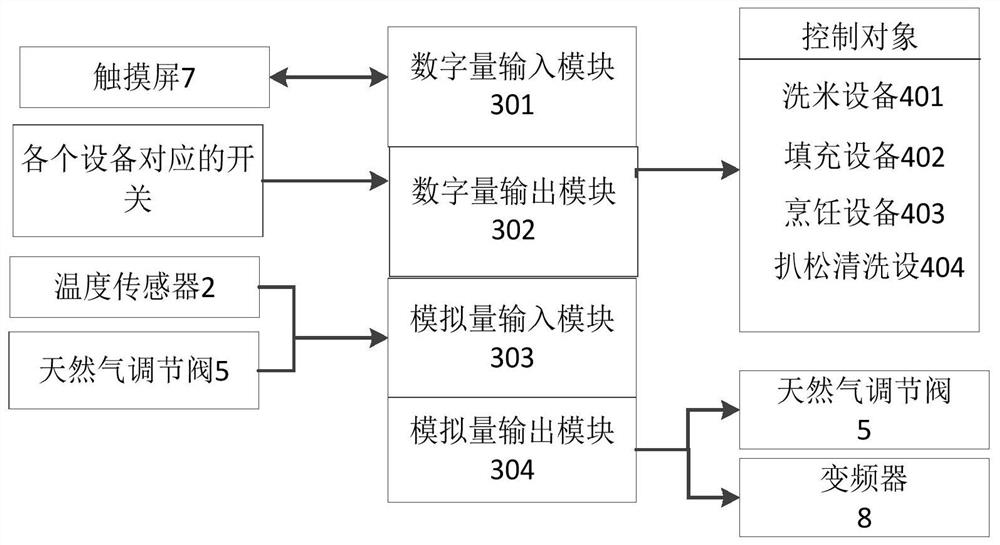

[0056] The embodiment of the present invention provides an industrial rice cooker control system, combining figure 1 look, figure 1 It is a structural schematic diagram of the industrial rice cooking machine control system provided by the present invention. The industrial rice cooking machine control system provided above includes an identification device 1, a temperature sensor 2, a PLC module 3, a rice cooking machine module 4, a natural gas regulating valve 5, and a transmission device 6, of which:

[0057] The identification device 1 is electrically connected to the PLC module 3, and is used to obtain the variety parameters of the rice to be cooked, and transmit the variety parameters to the PLC module 3;

[0058] The temperature sensor 2 is electrically connected to the PLC module 3, and is used to measure the heating temperature of the bottom of the pot of the rice cooking machine module 4, and transmit the heating temperature of the bottom of the pot to the PLC module ...

Embodiment 2

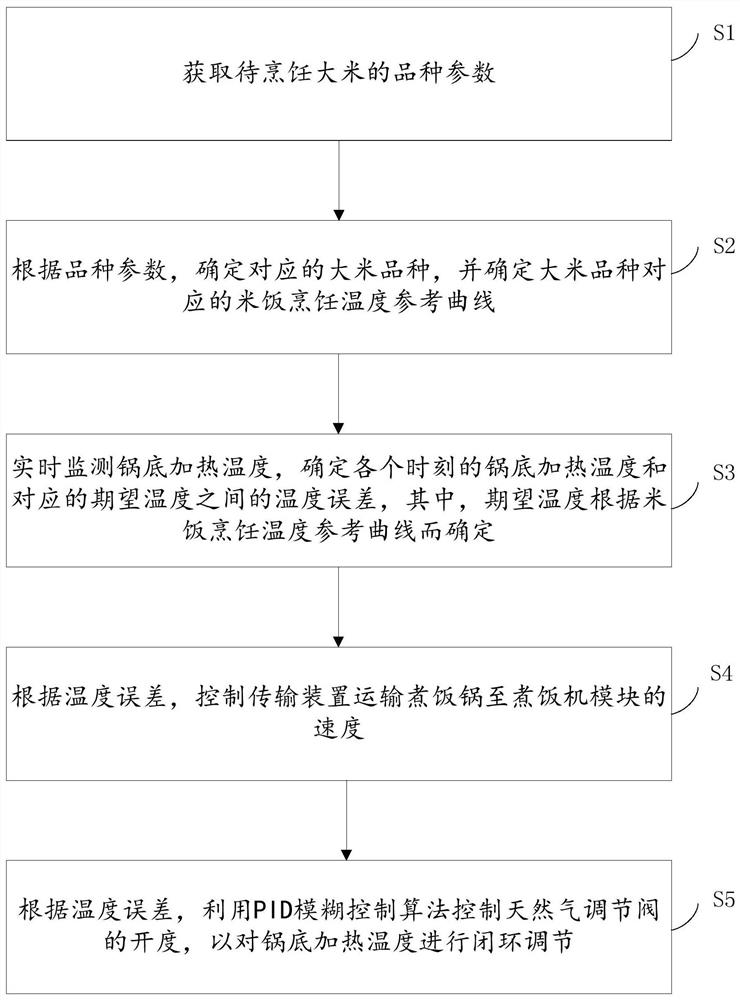

[0109] An embodiment of the present invention provides a control method for an industrial rice cooker, combining image 3 look, image 3 Schematic flow chart of the industrial rice cooker control method provided by the present invention Figure 1 , including steps S1 to S4, wherein:

[0110] In step S1, the variety parameter of the rice to be cooked is obtained;

[0111] In step S2, according to the variety parameter, determine the corresponding rice variety, and determine the rice cooking temperature reference curve corresponding to the rice variety;

[0112] In step S3, the heating temperature at the bottom of the pot is monitored in real time, and the temperature error between the heating temperature at the bottom of the pot at each moment and the corresponding desired temperature is determined, wherein the desired temperature is determined according to the rice cooking temperature reference curve;

[0113] In step S4, according to the temperature error, the speed at whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com