Liquid adhesive bandage and preparation method thereof

A liquid bandage, mass percentage technology, applied in medical science, bandages, etc., can solve the problems of liquid bandage nail polish pungent smell, infection, pain, etc., to promote wound healing and antibacterial effect, reduce cell Toxicity, enhance the effect of physiological activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

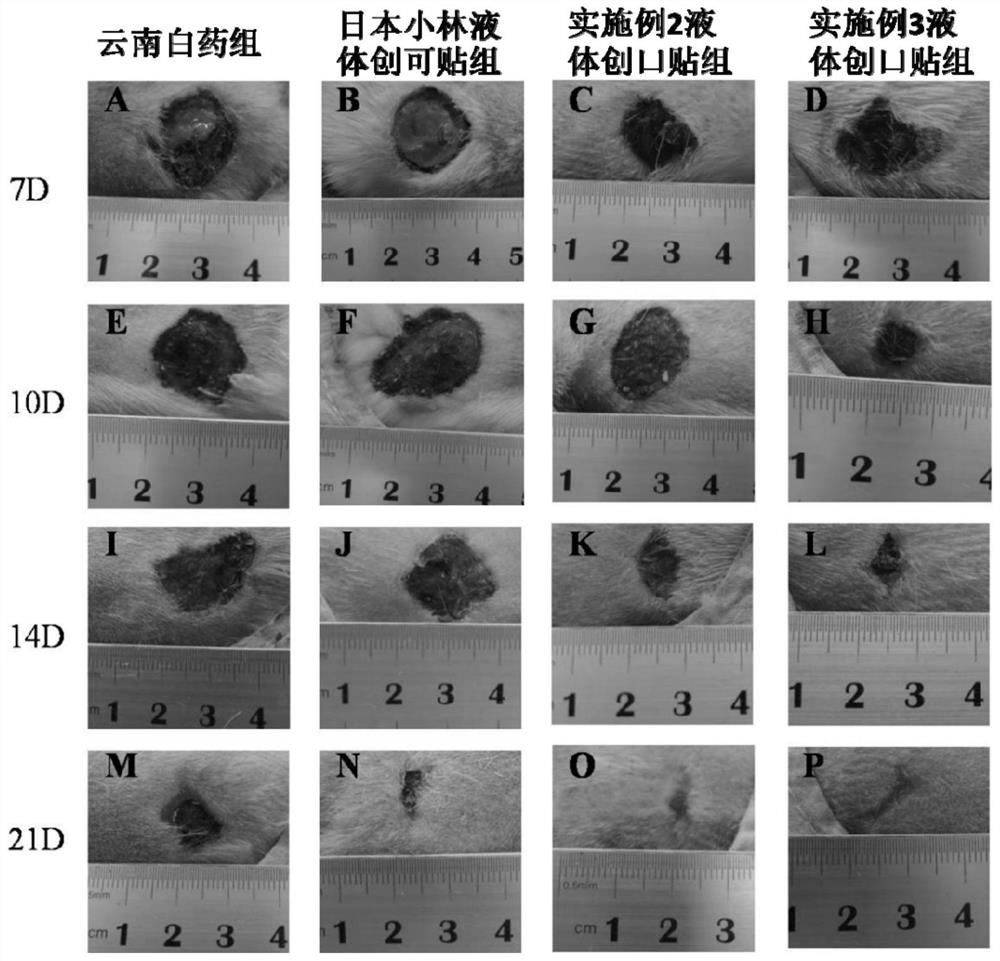

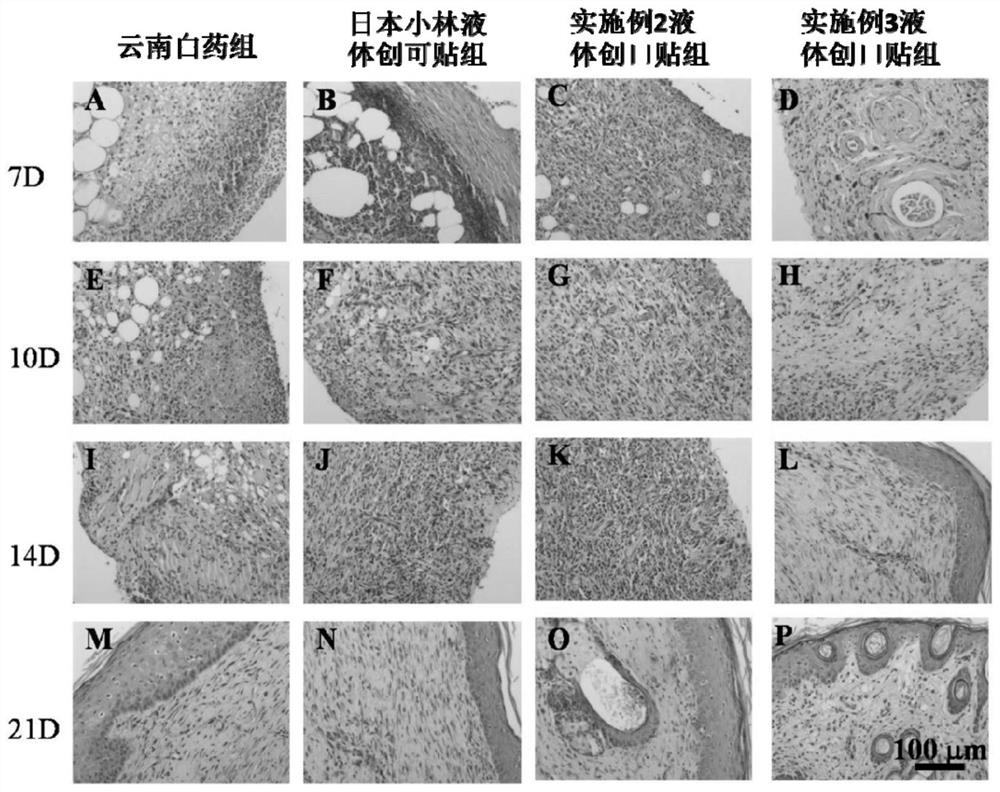

Examples

Embodiment 1

[0042] A liquid wound dressing is composed of a film-forming agent, a healing liquid and a bacteriostatic liquid, wherein the main component of the film-forming agent is polyvinyl butyral; the main components of the healing liquid are purified water, a moisturizing agent, a transparent Hyaluronic acid and asiaticoside, wherein the moisturizing agent is glycerin; the main components in the antibacterial solution are solvent, ethylparaben, antibacterial peptide, chitosan, viscosity modifier and plasticizer, wherein, the solvent is no Water ethanol, viscosity regulator is rosin, plasticizer is dibutyl phthalate and castor oil.

[0043] The mass percent of each component in the present embodiment liquid bandage is as follows:

[0044] 15% polyvinyl butyral, 13% purified water, 3% glycerin, 0.1% hyaluronic acid, 0.4% asiaticoside, 60% absolute ethanol, 0.5% ethylparaben , 0.5% antimicrobial peptides, 3% chitosan, 1.5% rosin, 2% dibutyl phthalate and 1% castor oil.

[0045] The pr...

Embodiment 2

[0050] A kind of liquid bandage, the difference with embodiment 1 is that the mass percentage of each component is different in the liquid bandage, the mass percentage of each component in the present embodiment liquid bandage is as follows:

[0051] 15% polyvinyl butyral, 13% purified water, 3% glycerin, 0.1% hyaluronic acid, 0.4% asiaticoside, 60% absolute ethanol, 0.5% ethylparaben , 0.5% antimicrobial peptides, 3% chitosan, 1.5% rosin, 2% dibutyl phthalate and 1% castor oil.

[0052] The liquid wound plaster of this embodiment can be prepared with reference to the preparation method given in Example 1, the difference is that in the method for preparing the liquid wound plaster in this embodiment, the stirring time in step (1) during the preparation of the healing liquid is 20 minutes; The stirring time during the preparation of the antibacterial solution in step (2) was 15 min; the temperature of the homogenization process in step (3) was 50° C., and the homogenization tim...

Embodiment 3

[0054] A kind of liquid bandage, the difference with embodiment 1 is that the mass percentage of each component is different in the liquid bandage, the mass percentage of each component in the present embodiment liquid bandage is as follows:

[0055] 12% polyvinyl butyral, 8% purified water, 4% glycerin, 0.1% hyaluronic acid, 0.5% asiaticoside, 65% absolute ethanol, 0.4% ethylparaben , 0.5% antimicrobial peptides, 3.5% chitosan, 2% rosin, 2.5% dibutyl phthalate and 1.5% castor oil.

[0056] The liquid wound plaster of this embodiment can be prepared with reference to the preparation method given in Example 1, the difference is that in the method for preparing the liquid wound plaster in this embodiment, the stirring time in step (1) during the preparation of the healing liquid is 15 minutes; The stirring time during the preparation of the antibacterial solution in step (2) was 15 minutes; the temperature of the homogenization process in step (3) was 45° C., and the homogenizat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com