A kind of branched polymer and its preparation method and application

A technology of branched polymers and polymers, applied in the direction of chemical instruments and methods, drilling compositions, etc., to achieve the effects of improving technical means, huge market value, and good leakage prevention and plugging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

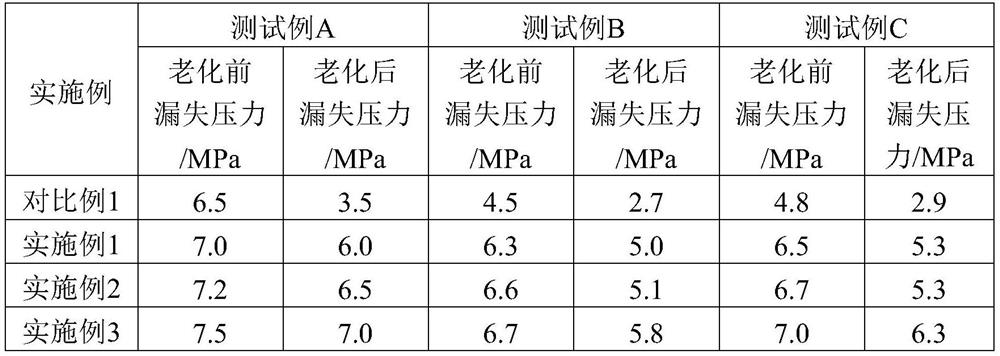

Examples

Embodiment 1

[0103] (1) Prepare A1 substance and B1 substance:

[0104] Substance A1 is ethylenediamine, molecular formula C 2 H 8 N 2 , i=2, j=0, the total amount of basic groups is x=2, and it is liquid at room temperature.

[0105] Substance B1 is 1,2,4-cyclohexanetricarboxylic acid anhydride, molecular formula C 9 H 10 O 5 , m=1, n=1, the total amount of acidic groups is y=3, and it is solid at room temperature. 1 / 3 mol of B1 substance was dissolved in DMF to prepare a 1M (mol / L) solution containing B1 substance (mixture containing B1 substance).

[0106] (2) Slowly add 0.2167 mol (a is 1.3, then 1.3 / 6 mol) of A1 substance into the solution containing B1 substance, control the dropwise temperature in an ice-water bath, and stir for 0.5 hours in an ice-water bath environment (0°C). During the period, nitrogen atmosphere was maintained after removing air and water vapor through nitrogen. The temperature was gradually raised to 60°C with stirring, and the reaction was carried out ...

Embodiment 2

[0110] (1) Prepare A2 substance and B2 substance:

[0111] Substance A2 is diethanolamine, molecular formula C 4 H 11 NO 2 , i=1, j=2, the total amount of basic groups is x=3, and it is liquid at room temperature.

[0112] Substance B2 is dodecanedioic acid, molecular formula C 12 H 22 O 4 , m=2, n=0, the total amount of acidic groups is y=2, and it is liquid at room temperature.

[0113] (2) Slowly add 0.1167mol (b is 0.7, then 0.7 / 6mol) of A2 substance into 0.5mol (1 / 2mol) of B2 substance, control the dropwise temperature in an ice-water bath, and stir for 1.5 hours in an ice-water bath environment , during which nitrogen atmosphere was maintained after removing air and water vapor through nitrogen. 0.01 mol of KOH (basic catalyst) was added, the temperature was gradually increased to 160°C under stirring, and the reaction was carried out for 4.5 hours to obtain a prepolymer.

[0114] (3) Add 0.1167mol (b is 0.7, then 0.7 / 3-0.7 / 6=0.7 / 6mol) A2 substance under stirring...

Embodiment 3

[0117] (1) Prepare A3 substance and B3 substance:

[0118] Substance A3 is 1,3-cyclohexanedimethylamine, molecular formula C 8 H 18 N 2 , i=2, j=0, the total amount of basic groups is x=2, it is liquid at normal temperature, and it is liquid at normal temperature.

[0119] Substance B3 is 1,2,3,4-cyclopentanetetracarboxylic dianhydride, molecular formula C 9 H 6 O 6 , m=0, n=2, the total amount of acidic groups is y=4, and it is solid at room temperature. Dissolve 1 / 4 mol of B3 in DMF to make a 1M solution containing B3.

[0120] (2) 0.375mol (a is 1.5, then 1.5 / 4mol) A3 substance is slowly added to the solution containing B3 substance, the temperature of dropwise addition is controlled in an ice-water bath, and stirred for 0.5 hours in an ice-water bath environment, during which nitrogen is removed to remove A nitrogen atmosphere was maintained after air and water vapor. The temperature was gradually raised to 100°C with stirring, and the reaction was carried out for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com