ALD machining equipment and method

A processing equipment and heater technology, which is applied in metal material coating technology, gaseous chemical plating, coating, etc., can solve the problems of poor uniformity of deposition film, waste of precursor source, and difficulty in quality assurance, and achieve short cycle time, The effect of improving utilization rate and reducing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] This embodiment discloses an ALD processing equipment.

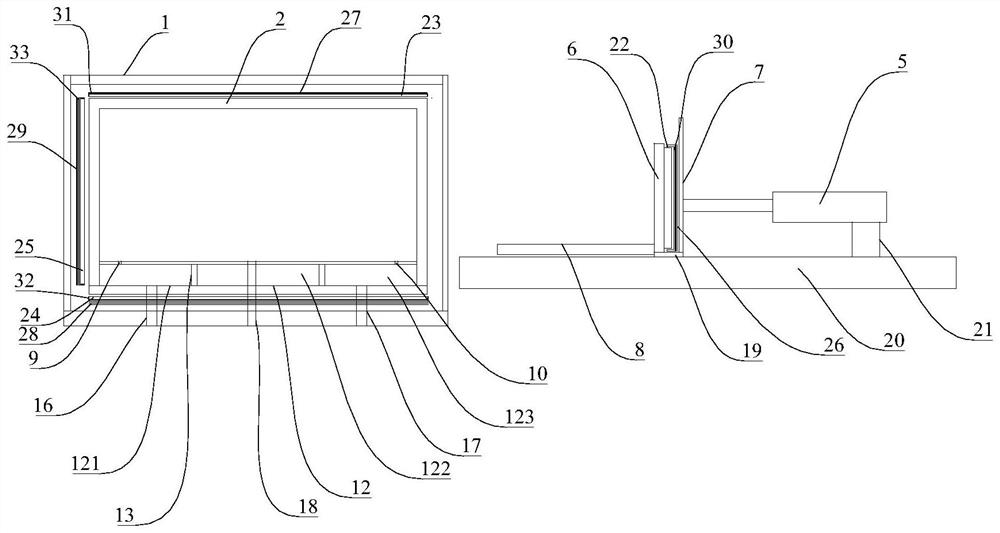

[0048] figure 1 It is a structural schematic diagram of a kind of ALD processing equipment of the present embodiment, combined with figure 1 , the ALD processing equipment of this embodiment includes a reactor and a conveying device.

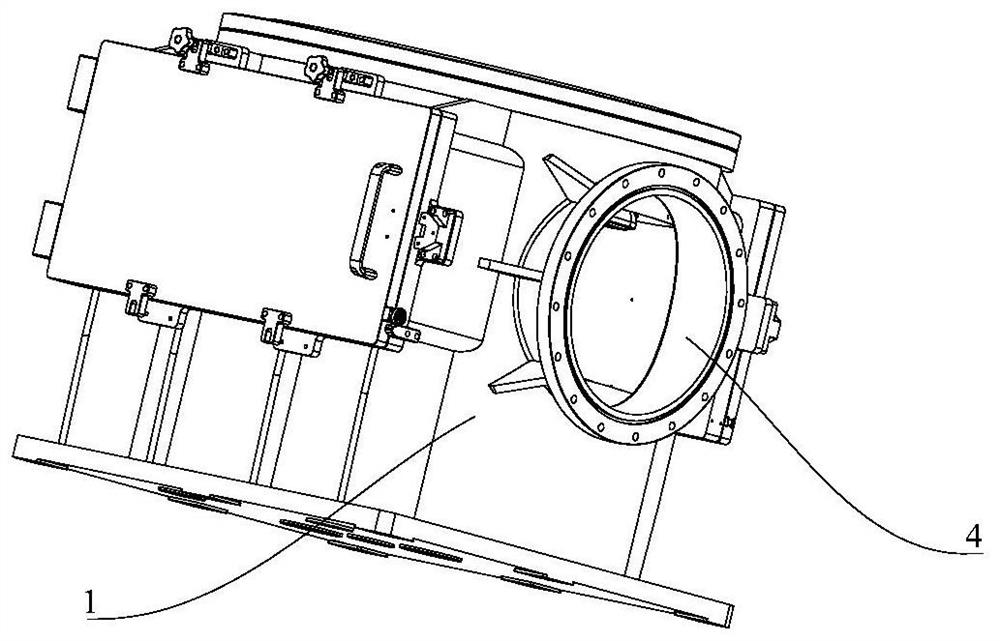

[0049] combine figure 1 , the reactor of this embodiment includes a vacuum chamber 1 and a reaction chamber 2, and the reaction chamber 2 is built in the vacuum chamber 1.

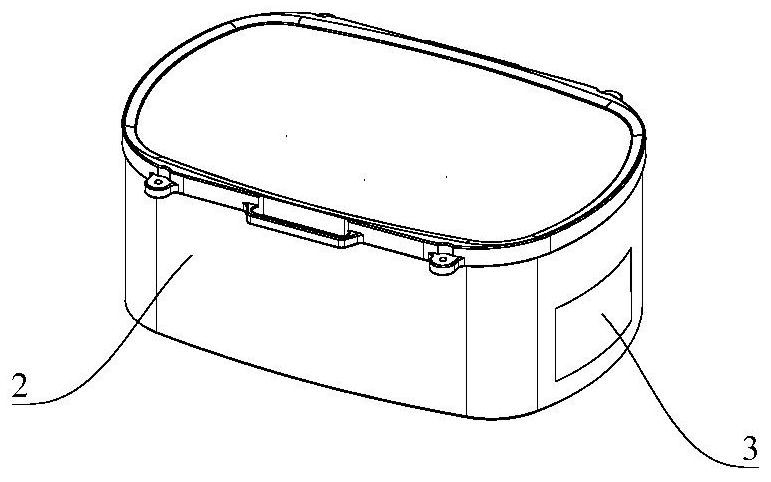

[0050] figure 2 It is a structural schematic diagram of the vacuum chamber of this embodiment, image 3 It is a structural schematic diagram of the reaction chamber of the present embodiment, combined with Figure 1-Figure 3, the side wall of the reaction chamber 2 of the present embodiment is provided with a first feed port 3, and the side wall of the vacuum chamber 1 is provided with a second feed port 4, and the first feed port and the second feed port are located at the side of the reactor. same side....

Embodiment 2

[0054] This embodiment provides a reaction chamber suitable for the ALD processing equipment shown in Embodiment 1.

[0055] Figure 4 It is a schematic top view of the reaction chamber of this embodiment, combined with image 3 as well as Figure 4 The bottom of the reaction chamber 2 in this embodiment is provided with an inlet channel 9 and an outlet channel 10 , and the inlet channel 9 and the outlet channel 10 are arranged opposite to each other at the center line of the bottom of the reaction chamber 2 .

[0056] During specific implementation, the precursor source is injected into the reaction chamber 2 from the inlet channel 9 of the reaction chamber 2, and is discharged from the gas outlet channel 10 of the reaction chamber 2, because the gas inlet channel 9 and the gas outlet channel 10 react with each other. The center line of the bottom of the chamber 2 is relatively arranged, therefore, the fluid field in the reaction chamber 2 is a laminar flow, and the intake ...

Embodiment 3

[0061] This embodiment provides a reaction chamber suitable for the ALD processing equipment shown in Embodiment 1 or 2.

[0062] Figure 5 It is a structural schematic diagram of the reaction chamber of Example 3. The difference between the reaction chamber shown in this embodiment and the reaction chamber shown in Example 2 is that two gas uniform plates 11 are arranged in the reaction chamber 2, Two gas uniform plates 11 are oppositely arranged with the center line of the bottom of the reaction chamber 2, and the two gas uniform plates 11 are arranged between the inlet channel 9 and the gas outlet channel 10, and the two gas homogenizer plates 11 divide the reaction chamber along the first The two directions are divided into an air inlet chamber, a reaction chamber and an air outlet chamber, and each gas uniform plate 11 is provided with a plurality of through holes.

[0063] The precursor source can enter the inlet chamber through the inlet channel 9, and then enter the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com