Composite fire-resistant fireproof cable and preparation method thereof

A fire-resistant cable and fire-resistant technology, which is used in cable/conductor manufacturing, insulated cables, cables, etc., can solve problems such as cable cracking and uneven performance of fire-resistant cable products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

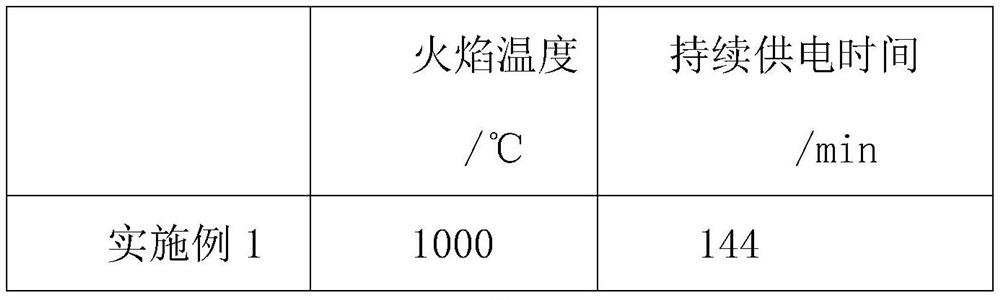

Embodiment 1

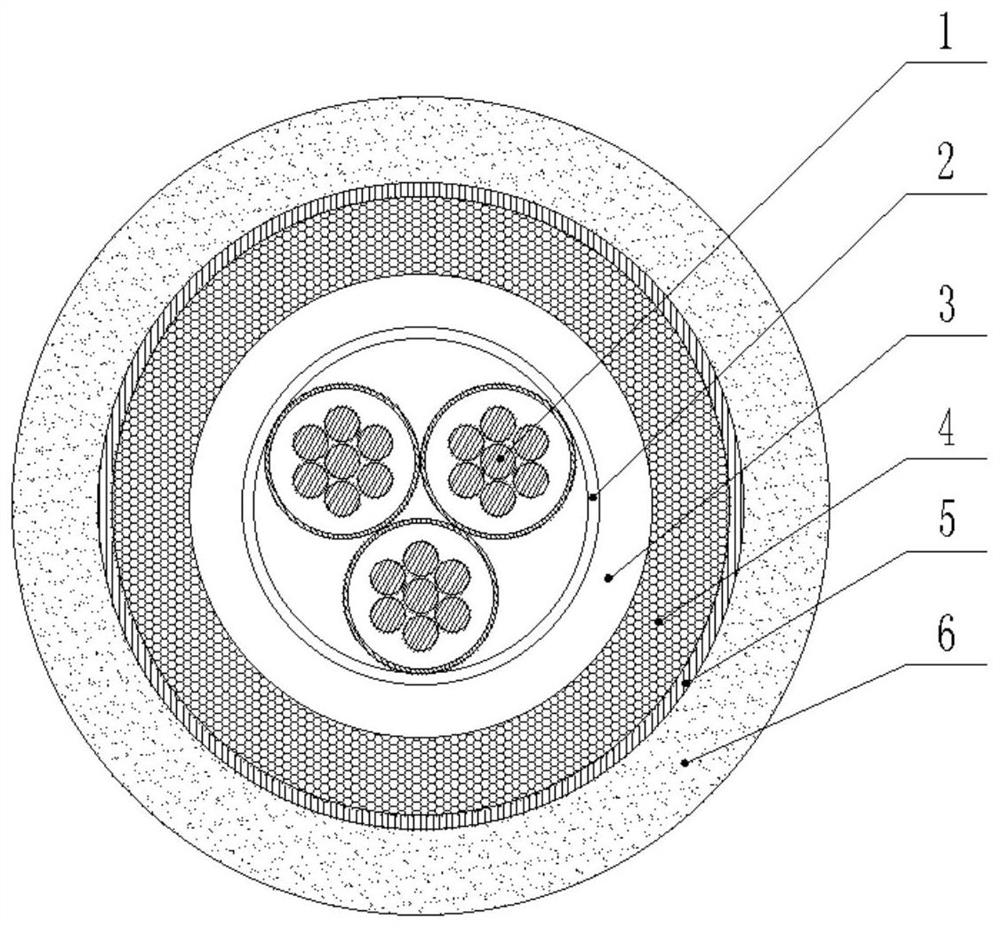

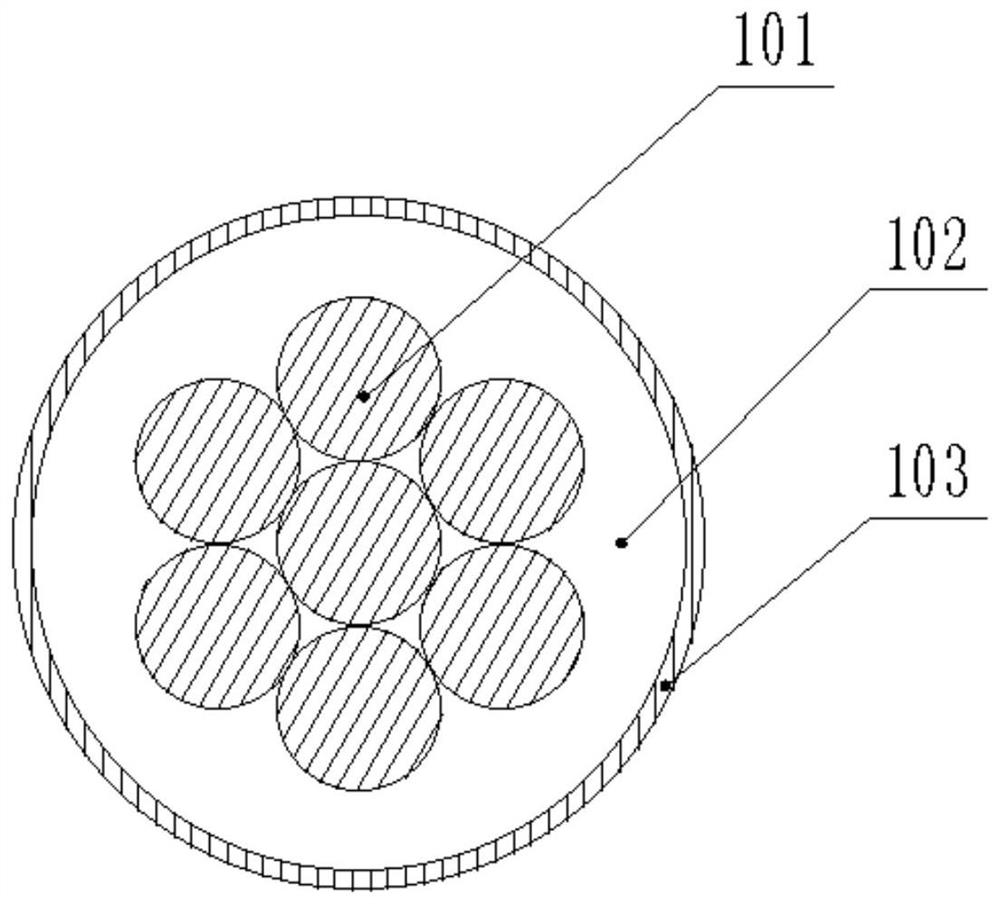

[0037] A composite fire-resistant type fireproof cable, including an outer sheath, the outer sheath is made of polyolefin composite insulating material;

[0038] The preparation method of polyolefin composite insulating material is as follows:

[0039]After impregnating nano-magnesia with KH-550 silane coupling agent 20 times its mass, oven-dried at 65°C to obtain modified nano-magnesia, and then mixed with low-density polyethylene, metallocene polyolefin elastomer, peroxide The cross-linking agent is blended together, and the weight ratio of modified nano-magnesia, low-density polyethylene, and metallocene polyolefin elastomer is 1:4:1, and they are added to a twin-screw extruder to extrude and granulate. The working temperature of the extruder is 135°C. Finally, the polyolefin composite insulating material can be obtained through air cooling, screening, magnetic separation and metering.

[0040] Steel tape armor layer;

[0041] Flame retardant interlayer;

[0042] The fla...

Embodiment 2

[0060] A composite fire-resistant type fireproof cable, including an outer sheath, the outer sheath is made of polyolefin composite insulating material;

[0061] The preparation method of polyolefin composite insulating material is as follows:

[0062] After impregnating nano-magnesia with KH-550 silane coupling agent 20 times its mass, oven-dried at 60°C to obtain modified nano-magnesia, and then mixed with low-density polyethylene, metallocene polyolefin elastomer, peroxide The cross-linking agent is blended together, and the weight ratio of modified nano-magnesia, low-density polyethylene, and metallocene polyolefin elastomer is 1:2:1, and they are added to a twin-screw extruder to extrude and granulate, and the twin-screw The working temperature of the extruder is 130°C. Finally, the polyolefin composite insulating material can be obtained through air cooling, screening, magnetic separation and metering.

[0063] Steel tape armor layer;

[0064] Flame retardant interlaye...

Embodiment 3

[0083] A composite fire-resistant type fireproof cable, including an outer sheath, the outer sheath is made of polyolefin composite insulating material;

[0084] The preparation method of polyolefin composite insulating material is as follows:

[0085] After impregnating nano-magnesia with KH-550 silane coupling agent 20 times its mass, oven-dried at 60°C to obtain modified nano-magnesia, and then mixed with low-density polyethylene, metallocene polyolefin elastomer, peroxide The cross-linking agent is blended together, and the weight ratio of modified nano-magnesia, low-density polyethylene, and metallocene polyolefin elastomer is 1:2:1, and they are added to a twin-screw extruder to extrude and granulate, and the twin-screw The working temperature of the extruder is 130°C. Finally, the polyolefin composite insulating material can be obtained through air cooling, screening, magnetic separation and metering.

[0086] Steel tape armor layer;

[0087] Flame retardant interlaye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com