Battery cell for three-electrode test and test method thereof

A three-electrode, cell technology, applied in circuits, electrical components, secondary batteries, etc., can solve problems such as potential instability, errors, and unsuitability for long-term continuous work, achieving the effect of good lithium analysis process and good data support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

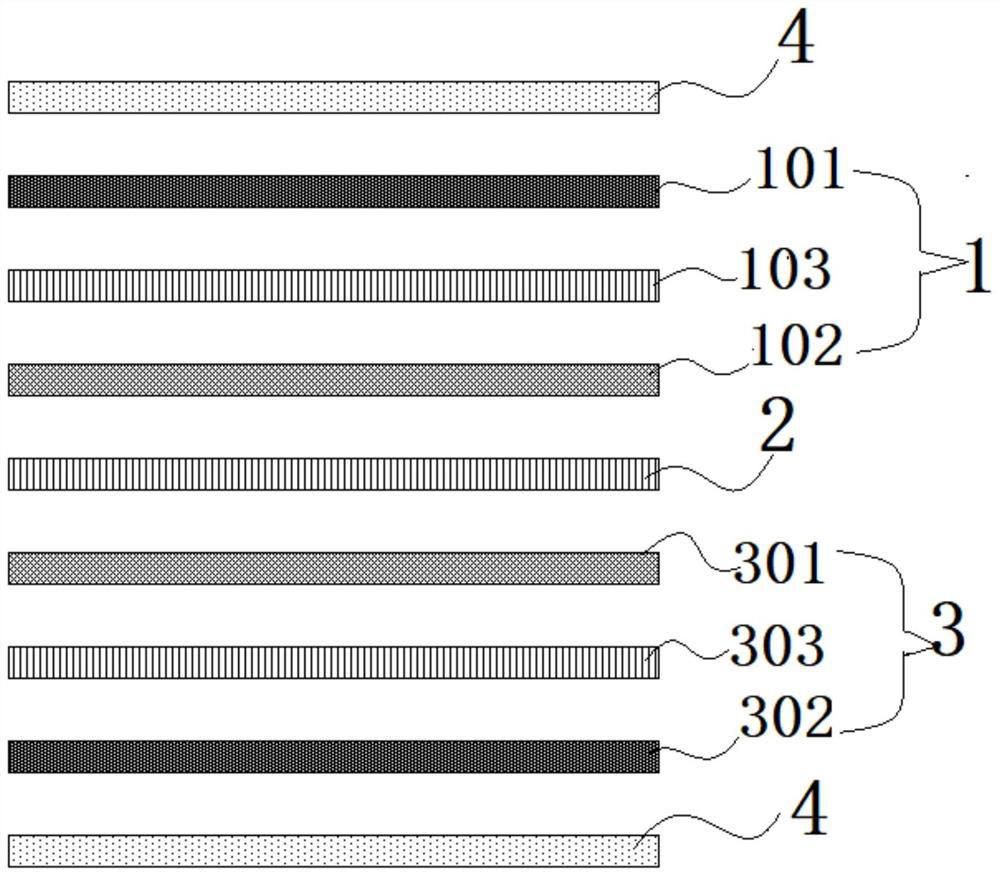

[0041] A method for preparing a cell for three-electrode testing, according to the cell for three-electrode testing, the specific steps are as follows:

[0042] S1. Preparation of basic roll core: make the basic roll core according to the steps of pulp mixing, coating, rolling, slitting, tab setting, and roll core assembly;

[0043] S2. Preparation of the third electrode unit: The third electrode unit is produced according to the steps of pulp mixing, coating, rolling, slitting, tab setting, and lamination, in which the single-layer positive electrode and the single-layer negative electrode are both coated on one side Structure, both back uncoated surface adhesive paper;

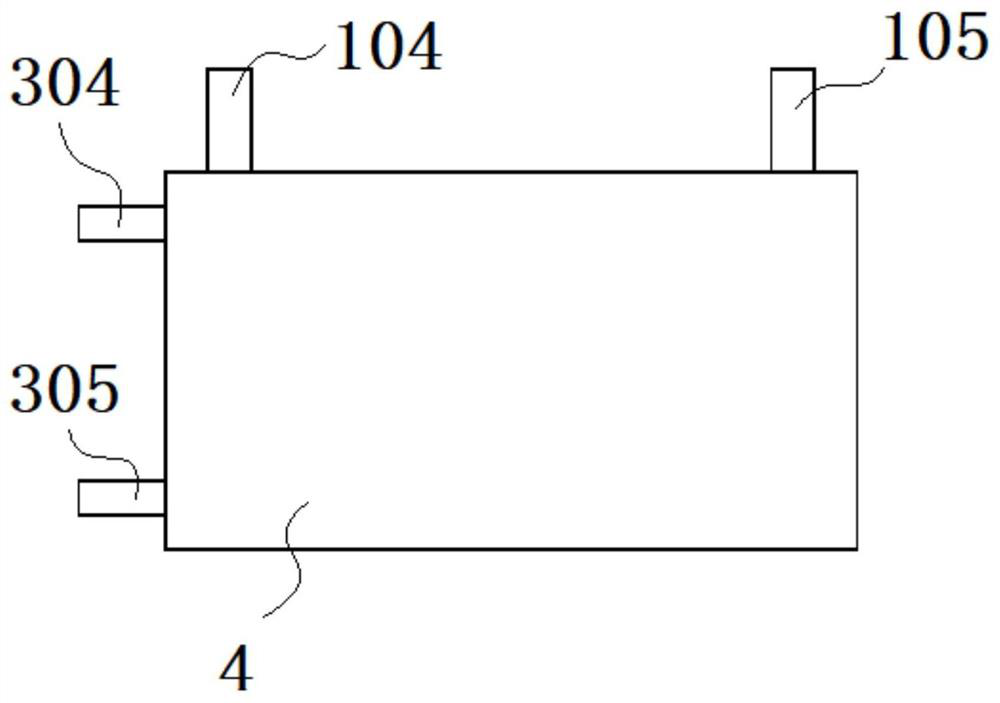

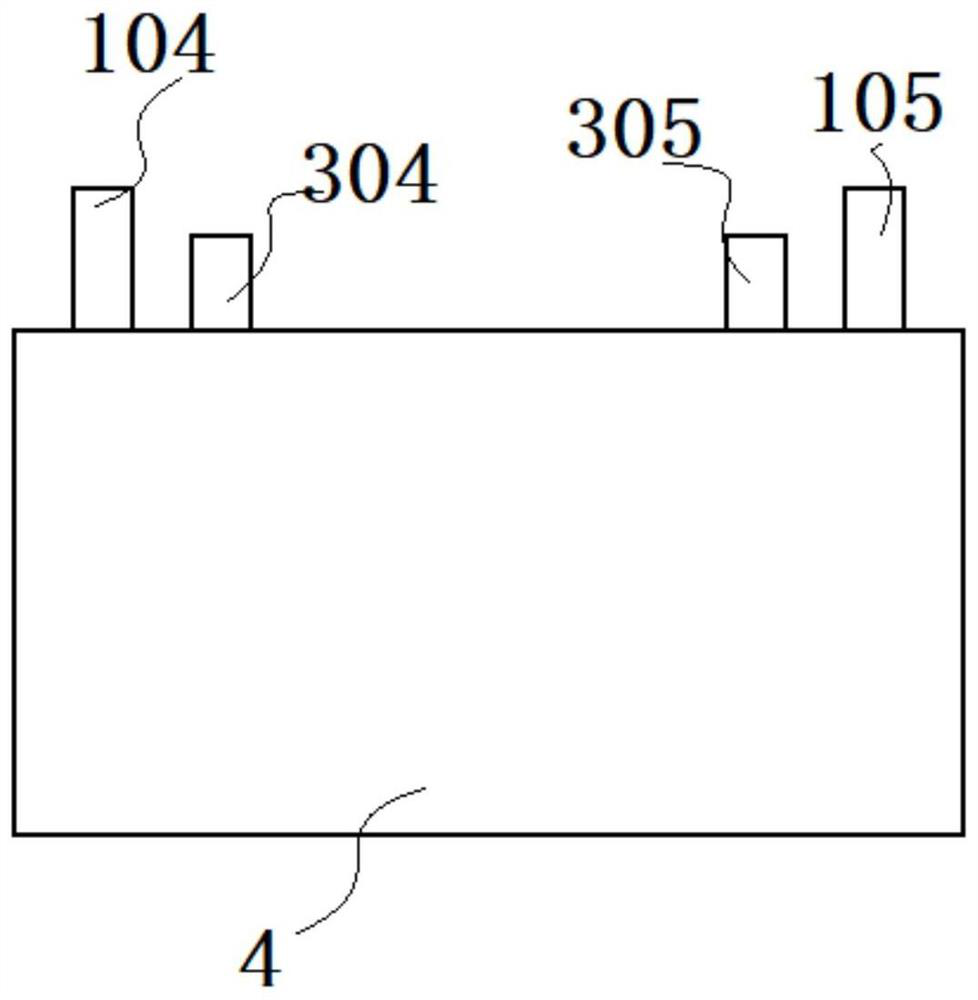

[0044] S3. Assemble into the case: put the basic core, separator, and third electrode unit into the punched aluminum-plastic packaging film in sequence, and adjust the positive and negative tabs of the basic core and the first tab and the third electrode unit of the third electrode unit. The direction of th...

specific Embodiment 1

[0054] Prepare the basic winding core, the formula of the positive electrode sheet is positive electrode active material (lithium cobaltate): conductive agent (carbon black): binding agent (polyvinylidene fluoride)=97:1.5:1.5, the formula of negative electrode sheet is negative electrode active material (middle phase carbon microspheres): conductive agent (graphite): CMC (sodium carboxymethylcellulose, thickener): SBR (styrene-butadiene rubber, binder) = 95:1:2:2.

[0055] Firstly, the positive and negative electrode slurries were prepared by stirring and mixing according to the above proportions, wherein the positive electrode used an oily system, and the negative electrode used a water-based system. When stirring and mixing, the double planetary stirring equipment is used to prepare the slurry under the condition of controlling the temperature and the degree of vacuum. After testing the viscosity, solid content and fineness of the slurry to meet the requirements, the slurry i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com