Cascade type plasma generator

A technology of plasma and generator, which is applied in the field of plasma, can solve the problems of high-frequency plasma torch being easily damaged, hindering industrial application, and low yield of fine powder, so as to improve the service life, solve the loss of electrode materials, Ease of disassembly and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below by means of the accompanying drawings and specific embodiments.

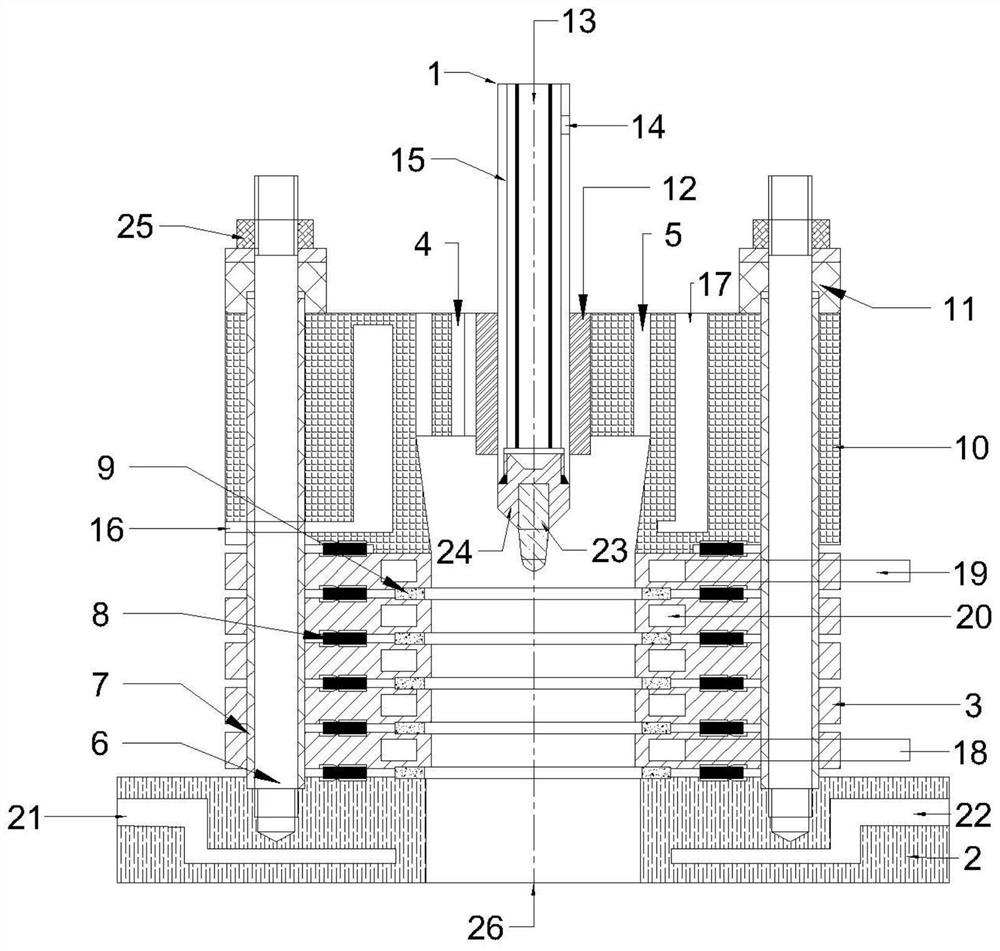

[0021] The cascaded plasma generator includes a cathode assembly 1 , a cathode seat 10 on which the cathode assembly 1 is installed, several layers of cascade plates 3 installed below the cathode seat 10 and an anode 2 installed below the cascade plate 3 .

[0022] Among them, the cathode assembly 1 includes a cathode head 23, a copper seat 24 and a cathode cooling jacket 15. The copper seat 24 is connected to the cathode cooling jacket 15 by threads, and a certain gap channel is reserved between the copper seat 24 and the cathode cooling jacket 15, which is called cooling. The water channel is used to cool the cathode, and the top and side of the cathode cooling jacket 15 are respectively processed with a cooling water inlet 13 and an outlet 14 .

[0023] Copper seat 24 is coaxially installed with the above-mentioned cathode cooling jacket 15, one end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com