Emulsion type reverse demulsifier for offshore oilfield and preparation method of emulsion type reverse demulsifier

An anti-phase demulsifier and offshore oilfield technology, applied in the field of emulsion-type inverse demulsifier for offshore oilfields and its preparation, can solve problems such as easy to hang on the wall, unable to quickly sweep oil beads, and difficult to compound

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

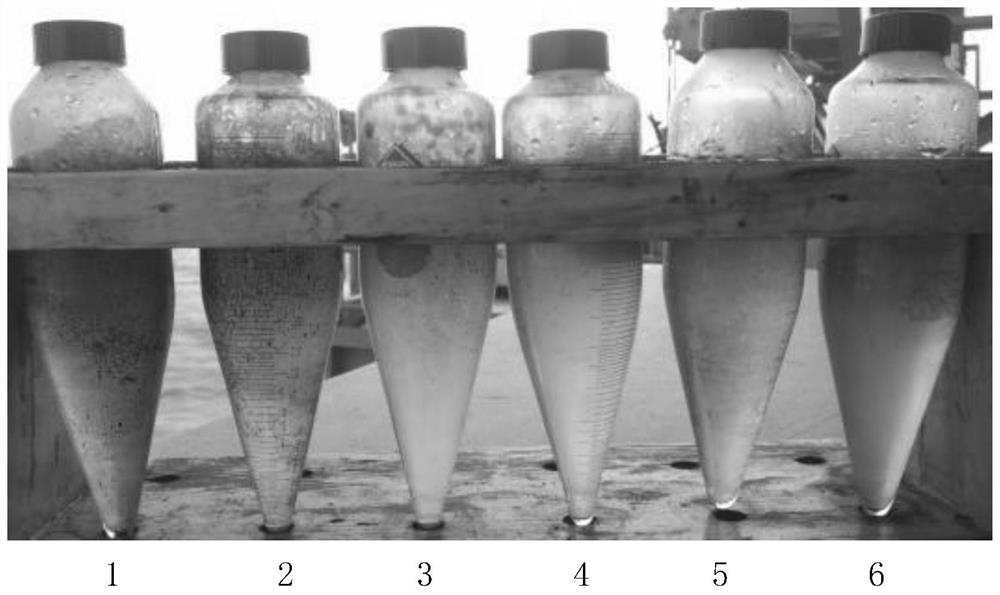

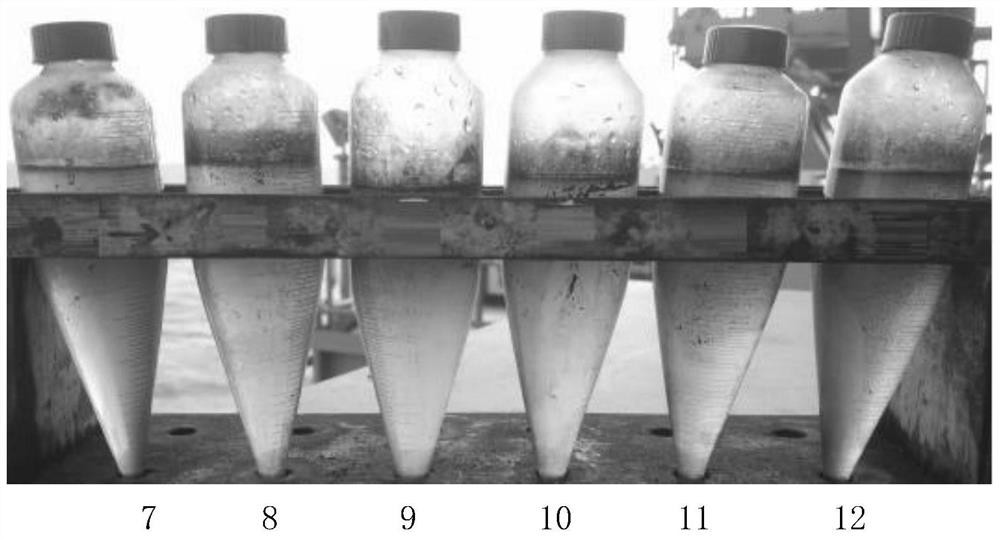

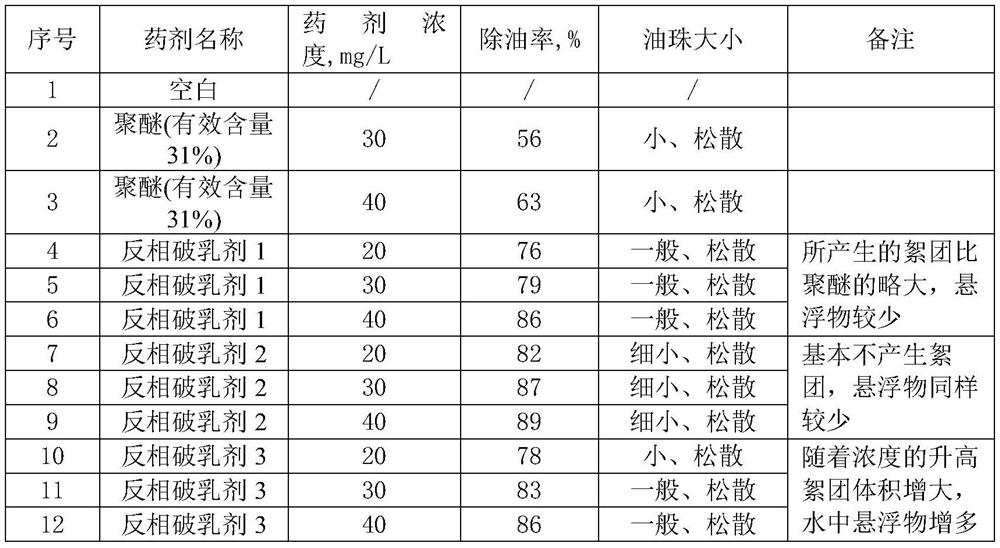

Examples

Embodiment 1

[0029] The preparation of embodiment 1 emulsion type inverse demulsifier

[0030] Pour 50g of distilled water into the four-necked flask first, and after the temperature is controlled to 40°C, start stirring, then slowly drop 35g of the melted diethanolamine resin polyether dry agent into the four-necked flask, and continue stirring for 6 hours after the addition is completed. Then add 25 g of a copolymer of dimethyl diallyl ammonium chloride and acrylamide (effective content 19%), and continue to stir for 2 hours; when the water bath rises to 55° C., start stirring, and dropwise add ethylene glycol into the aqueous phase solution. Add 10 g of alcohol monobutyl ether, and continue stirring for 2 hours after the dropwise addition; then add 8.5 g of ammonium sulfate to the aqueous phase solution, and after it is completely dissolved, continue stirring for 3 hours to obtain emulsion-type inverse demulsifier 1.

Embodiment 2

[0031] The preparation of embodiment 2 emulsion type inverse demulsifier

[0032] First pour 50g of distilled water into the four-necked flask, and after the temperature is controlled to 40°C, start stirring, then slowly drop 40g of the melted diethanolamine resin polyether dry agent into the four-necked flask, and continue to stir for 6 hours after the dropping is completed. Then add 20 g of a copolymer of dimethyl diallyl ammonium chloride and acrylamide (effective content 19%), and continue to stir for 2 hours; when the water bath rises to 55° C., start stirring, and dropwise add ethylene glycol into the aqueous phase solution. Add 10 g of alcohol monobutyl ether, and continue to stir for 2 hours after the dropwise addition; then add 8.5 g of ammonium sulfate to the aqueous phase solution, and after it is completely dissolved, continue to stir for 3 hours to obtain emulsion-type inverse demulsifier 2.

Embodiment 3

[0033] The preparation of embodiment 3 emulsion type inverse demulsifier

[0034] First pour 50g of distilled water into the four-necked flask, and after it is controlled to 40°C, start stirring, then slowly drop 45g of the melted diethanolamine resin polyether dry agent into the four-necked flask, and continue to stir for 6 hours after the addition is completed. Then add 15 g of a copolymer of dimethyl diallyl ammonium chloride and acrylamide (effective content 19%), and continue to stir for 2 hours; when the water bath rises to 55° C., start stirring, and dropwise add ethylene glycol into the aqueous phase solution. Add 10 g of alcohol monobutyl ether, and continue to stir for 2 hours after the dropwise addition; then add 8.5 g of ammonium sulfate to the aqueous phase solution, and after it is completely dissolved, continue to stir for 3 hours to obtain emulsion-type inverse demulsifier 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com