Sludge drying odor treatment method and device

A technology for sludge drying and treatment methods, applied in chemical instruments and methods, separation methods, air quality improvement, etc., can solve problems such as increased operating costs, secondary pollution, and difficult long-term operation of biological washing tanks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

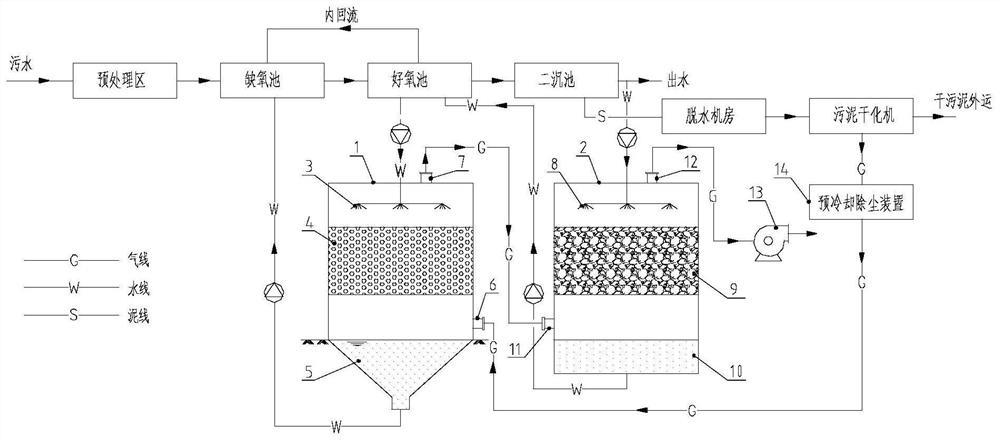

[0034] like figure 1 As shown, this embodiment discloses a sludge drying and odor treatment device, which is used in conjunction with a sewage treatment system, and mainly includes a biological washing tank 1, a biological trickling filter tank 2, a fan 13, a pre-cooling and dust removal device 14 and supporting Piping, pumps, valves and control systems.

[0035] Among them, the sewage treatment system includes a pretreatment area, anoxic tank, aerobic tank, secondary sedimentation tank, dehydration machine room and sludge drying machine connected in sequence. The aerobic tank is also connected to the anoxic tank through a return pipe.

[0036] A washing spray device 3 , a washing packing layer 4 and a washing liquid collection area 5 are sequentially arranged in the biological washing tank 1 from top to bottom. Wherein, the filler of the washing filler layer 4 is a hollow polyhedron plastic ball with a diameter ranging from 3 to 5 cm and a specific surface area of 200 to 3...

Embodiment 2

[0045] This embodiment discloses a sludge drying and odor treatment method, which is implemented based on the device in Embodiment 1, and specifically includes:

[0046] The high-concentration sulfur-containing and nitrogen-containing odor generated during the sludge drying process is collected and processed by the pre-cooling and dust removal device 14, and then driven by the fan 13, enters the biological washing tank 1 through the air inlet 6 of the biological washing tank, It passes through the washing packing layer 4 from bottom to top, and enters the biological trickling filter 2 through the gas outlet 7 of the biological washing tank and the air inlet 11 of the biological trickling filter in sequence.

[0047] The mud-water mixture in the front section of the aerobic tank is pumped by the washing spray pump to the washing spray device 3 on the top of the biological washing tank 1, sprayed from top to bottom through the nozzle, and forms countercurrent contact with the odo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter range | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com