A zeolite molecular sieve modified silicon source prepared by enhanced dissolution method

A technology of zeolite molecular sieve and silicon source, applied in molecular sieves and alkali exchange compounds, chemical instruments and methods, crystalline aluminosilicate zeolites, etc., can solve the problem of increasing solvent consumption, energy consumption and processing costs, and poor stability of high-concentration solutions The problem of high efficiency and simple preparation method can be achieved by solving the problems of non-resistance, difficult zeolite molecular sieve preparation raw materials and other problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

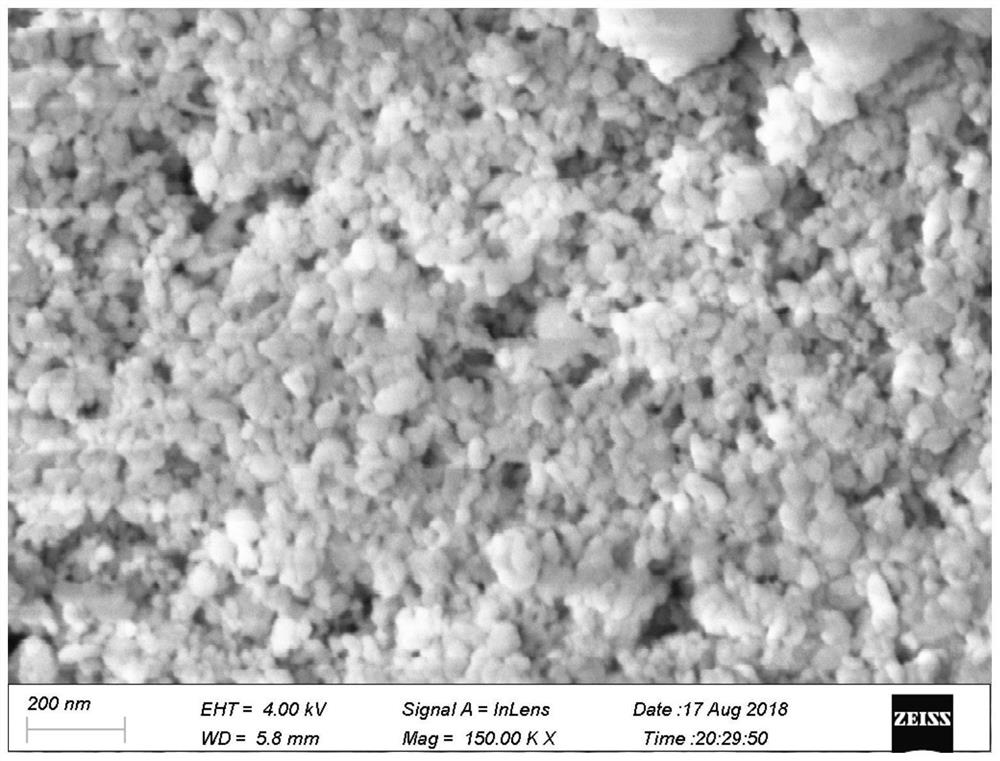

[0050] (1) Soak the dense silicon source dry colloidal silicon in aqua regia, 38% concentrated hydrochloric acid or 68% concentrated nitric acid solution for 12 hours.

[0051] (2) The mixture in (1) is ground in a high-energy ball mill, the rotational speed is 1500 r / min, the ball-to-material ratio is 10:1, and the grinding time is 8 hours.

[0052] (3) prepare the aqueous solution of methanol, add potassium hydroxide to adjust the pH value to 14, transfer the silicon raw material processed in step (2) to the hydrothermal synthesis kettle, under the temperature condition of 180 ℃, in alkaline methanol Dissolved in aqueous solution for 5 hours.

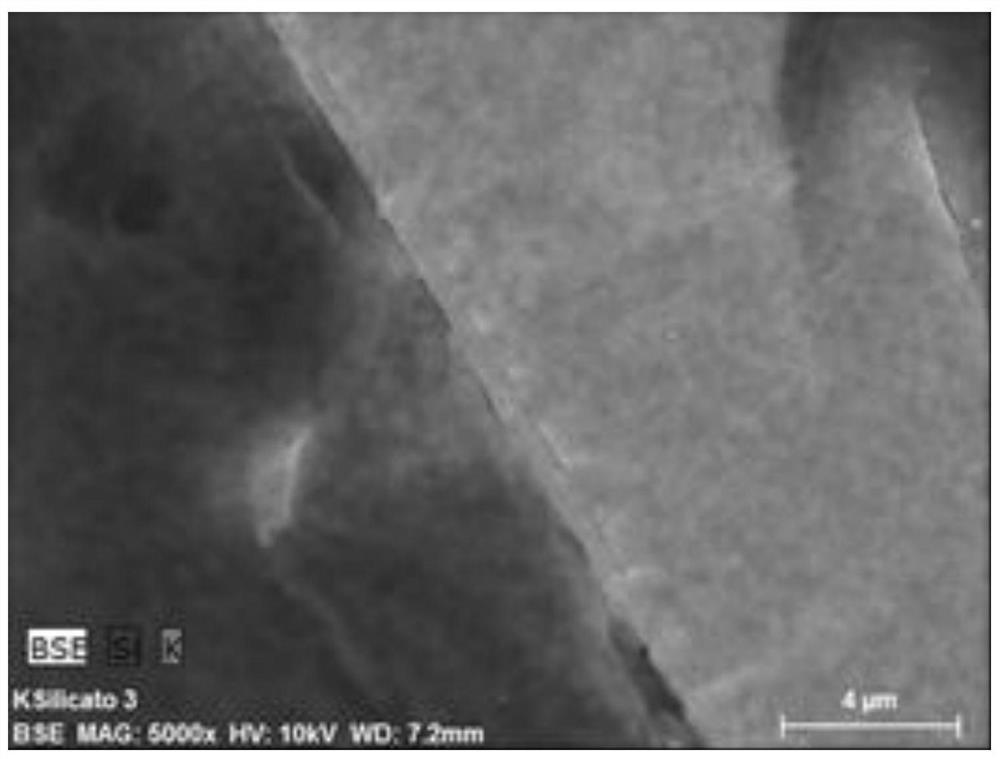

[0053] (4) A potassium bromide aqueous solution with a concentration range of 0.1 mol / L is prepared, and is added dropwise and mixed with the silicon solution in (3) under high-intensity stirring conditions.

[0054] (5) The stable mixed solution prepared in (4) was sprayed on the hot metal plate using a coating machine. The tempera...

Embodiment 2

[0057] In step (1), 1 mol / L of relatively dilute hydrochloric acid or nitric acid is used, and the effect of soaking within one day on the removal of impurities is limited, and the soaking time needs to be extended to about 3 days. Other operations are the same as (2-5) or (2-6) in Example 1, and similar effects can also be obtained.

Embodiment 3

[0059] The effect of freeze drying (-20°C overnight drying) in step (5) is slightly inferior to spray drying, and the silicon material has a slight self-agglomeration phenomenon, but it can still play a promoting role in step (6).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com