Innocent treatment method for endotoxin-containing sludge in sewage treatment plant

A sewage treatment plant and harmless treatment technology, applied in the field of environmental pollution control, can solve problems such as high cost and secondary pollution, and achieve the effects of reducing endotoxin, good purification effect, and good killing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

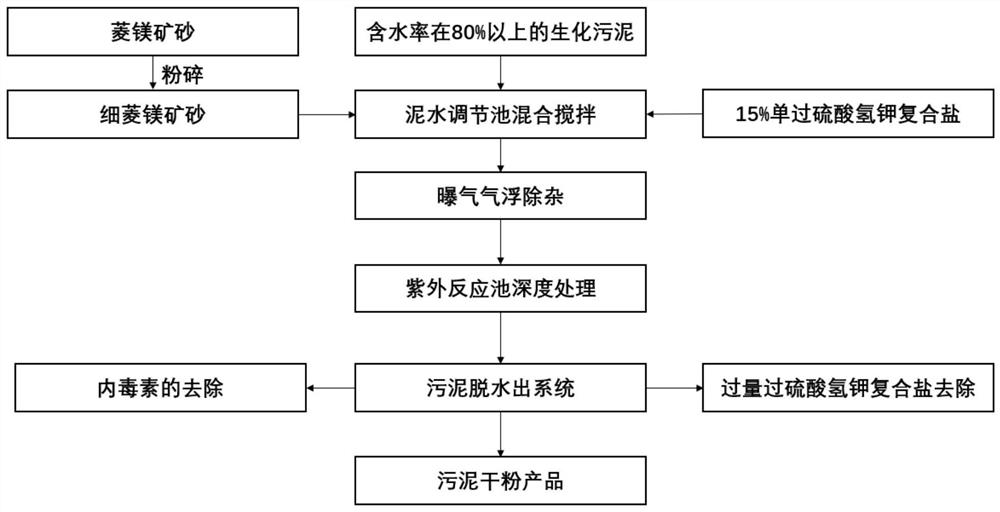

[0027] Such as figure 1 As shown, a method for harmless treatment of endotoxin-containing sludge in a sewage treatment plant is implemented according to the following steps:

[0028] Firstly, the crushing of magnesite is carried out, the coarse magnesite sand is collected, first crushed into particles with a particle size below 30mm by a jaw crusher, and then further crushed into small particles below 2mm by a double-roller crusher to obtain powdered magnesite ore; then collect the water-containing sludge, collect the sludge with a water content above 80% discharged from the sewage treatment plant, and place it in the mud-water adjustment tank; then add catalysts, add an amount equivalent to the mud-water mixture in the mud-water adjustment tank 2% magnesite sand, control the speed of frame mixer at 5 rpm, and continue to stir for 2 hours; add oxidant again, and slowly add potassium monopersulfate compound salt with a mass concentration of 15% equivalent to 0.5% of the volume ...

Embodiment 2

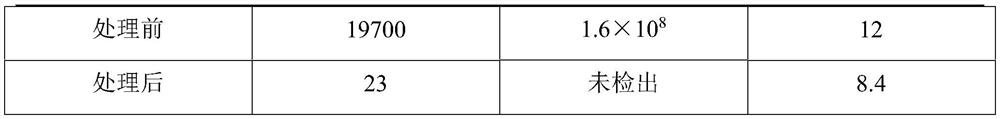

[0030] The anaerobic biochemical sludge of a municipal domestic sewage treatment plant in Beijing is disposed of with the method described in Example 1, and the results are as follows:

[0031]

[0032]

Embodiment 3

[0034] The anaerobic biochemical sludge of a coking plant sewage treatment plant in Xingtai City was disposed of with the method described in Example 1, and the results were as follows:

[0035] Concentration of pollutants Endotoxin (EU / g) Total number of bacteria (MPN / kg) Organic matter (%) before processing 6700 4.4×10 4

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com