High-temperature-resistant polylactic resin and modification production process thereof

A technology for polylactic acid resin and production process, which is applied in the field of polylactic acid resin, can solve problems such as troublesome production process, unfavorable processing and production, and increased production cost, so as to facilitate processing and production, increase toughness and strength, and save energy. The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

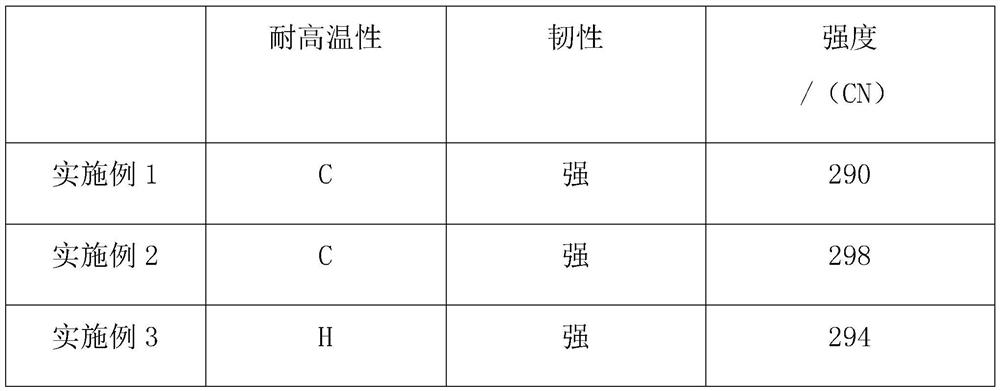

Embodiment 1

[0027] A high-temperature-resistant polylactic acid resin, the formula includes: triglycidyl isocyanurate, polylactic acid resin, calcium carbonate, catalyst, antioxidant and plasticizer, and the mass percentages of each component are: 15 parts Triglycidyl isocyanurate, 60 parts of polylactic acid resin, 25 parts of calcium carbonate, 20 parts of catalyst, 5 parts of antioxidant and 20 parts of plasticizer.

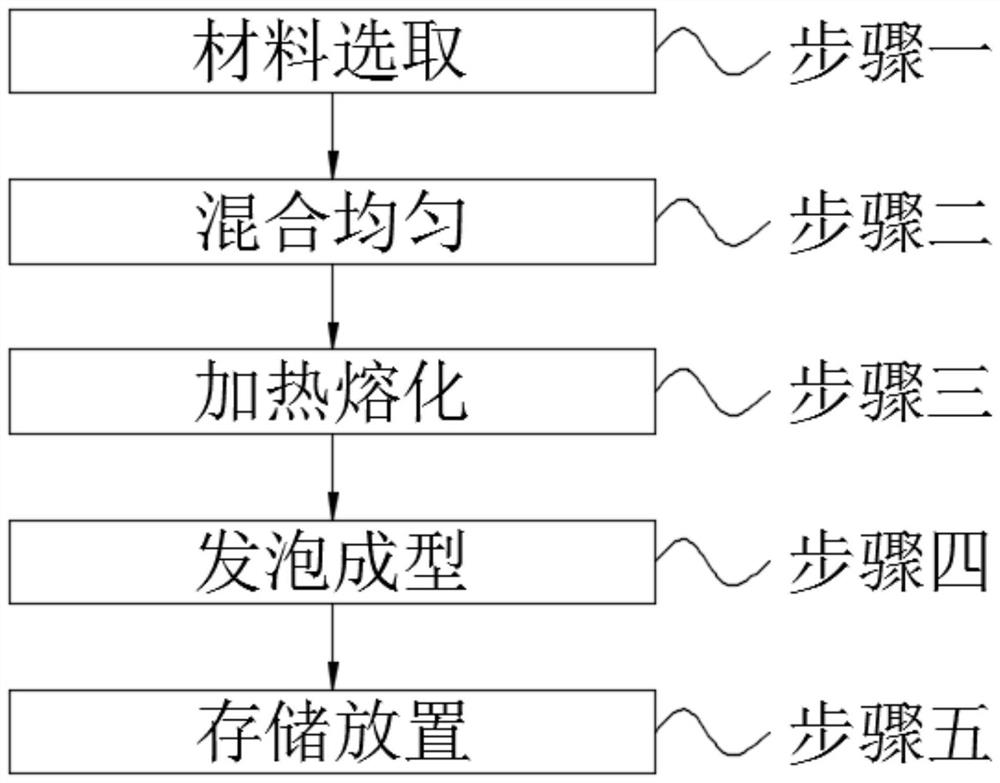

[0028] A modified production process of high temperature resistant polylactic acid resin, comprising the following steps: step 1, material selection; step 2, mixing uniformly; step 3, heating and melting; step 4, foam molding; step 5, storing and placing;

[0029] Wherein in the above-mentioned step one, according to the content of each component is respectively: 15 parts of triglycidyl isocyanurate, 60 parts of polylactic acid resin, 25 parts of calcium carbonate, 20 parts of catalyst, 5 parts of antioxidant and 20 parts of plasticizers are selected and weighed;

[0030...

Embodiment 2

[0041] A high-temperature-resistant polylactic acid resin, the formula includes: triglycidyl isocyanurate, polylactic acid resin, calcium carbonate, catalyst, antioxidant and plasticizer, and the mass percentages of each component are: 20 parts Triglycidyl isocyanurate, 50 parts of polylactic acid resin, 25 parts of calcium carbonate, 20 parts of catalyst, 5 parts of antioxidant and 20 parts of plasticizer.

[0042] A modified production process of high temperature resistant polylactic acid resin, comprising the following steps: step 1, material selection; step 2, mixing uniformly; step 3, heating and melting; step 4, foam molding; step 5, storing and placing;

[0043] Wherein in the above step 1, according to the content of each component, it is respectively: 20 parts of triglycidyl isocyanurate, 50 parts of polylactic acid resin, 25 parts of calcium carbonate, 20 parts of catalyst, 5 parts of antioxidant and 20 parts of plasticizers are selected and weighed;

[0044] Wherei...

Embodiment 3

[0055] A high-temperature-resistant polylactic acid resin, the formula includes: triglycidyl isocyanurate, polylactic acid resin, calcium carbonate, catalyst, antioxidant and plasticizer, and the mass percentages of each component are: 25 parts Triglycidyl isocyanurate, 40 parts of polylactic acid resin, 25 parts of calcium carbonate, 20 parts of catalyst, 5 parts of antioxidant and 20 parts of plasticizer.

[0056] A modified production process of high temperature resistant polylactic acid resin, comprising the following steps: step 1, material selection; step 2, mixing uniformly; step 3, heating and melting; step 4, foam molding; step 5, storing and placing;

[0057] Wherein in the above-mentioned step one, according to the content of each component is respectively: 25 parts of triglycidyl isocyanurate, 40 parts of polylactic acid resin, 25 parts of calcium carbonate, 20 parts of catalyst, 5 parts of antioxidant and 20 parts of plasticizers are selected and weighed;

[0058...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com