Green environment-friendly water-based flat coating system and preparation method thereof

A green, environmentally friendly, water-based multi-color paint technology, applied in the direction of coating, can solve the problems of water-based multi-color paint waste recycling difficulties, environmental hazards and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

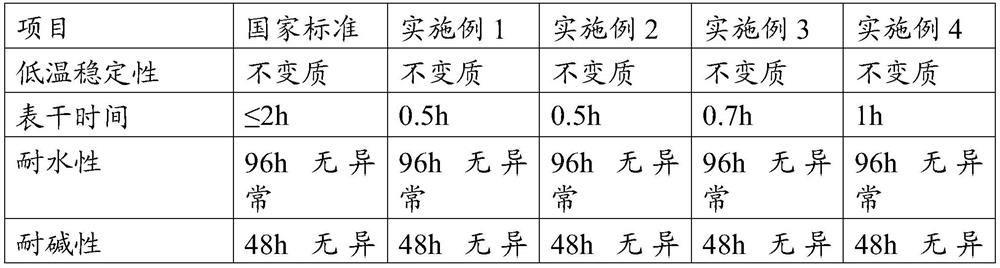

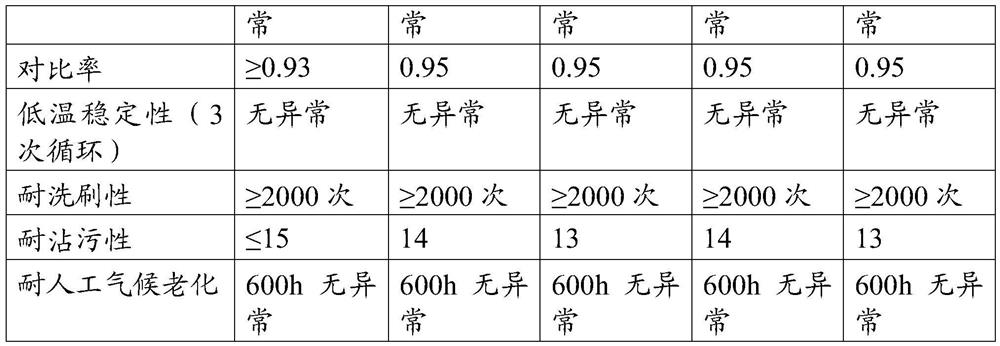

Examples

Embodiment 1

[0028] A green and environment-friendly water-based flat coating system, comprising the following components by mass: 25 parts of water, 10 parts of water-based colorful paint recovery premix, 17 parts of film formers, 0.5 parts of thickening system, 3 parts of additives, 41 parts of pigments and fillers .

[0029] The thickening system in the water-based flat coating system includes the following components in parts by mass: 0.3 parts of hydrophobically modified alkali-swellable thickener; 0-0.3 parts of hydroxyethyl cellulose; 0-0.2 parts of polyurethane thickener;

[0030] The additives in the water-based flat coating system include the following components by mass: 1 part of propylene glycol, 1 part of alcohol fat, 0.1 part of non-ionic alkylphenol polyoxyethylene ether, 0.6 part of sodium polyacrylic acid; 0.1 part of mineral oil defoamer 0.1 part of PH regulator (amine multifunctional auxiliary agent), 0.3 part of preservative;

[0031] The pigments and fillers in the w...

Embodiment 2

[0034] A green and environment-friendly water-based flat coating system, including the following components by mass: 22 parts of water, 15 parts of recycled premix for water-based colorful paint, 16 parts of film-forming material, 0.5 parts of thickening system, 3 parts of additives, and 39 parts of pigments and fillers .

[0035] The thickening system in the water-based flat coating system includes the following components in parts by mass: 0.3 parts of hydrophobically modified alkali-swellable thickener; 0-0.3 parts of hydroxyethyl cellulose; 0-0.2 parts of polyurethane thickener;

[0036] The auxiliary agent in the water-based flat coating system includes the following components in parts by mass: 1 part of propylene glycol, 1 part of alcohol fat, 0.1 part of nonionic alkylphenol polyoxyethylene ether, 0.6 part of sodium polyacrylic acid; mineral oil defoamer 0.1 part; 0.1 part of PH regulator (amine multifunctional additive), 0.3 part of preservative;

[0037] The pigment...

Embodiment 3

[0040] A green and environment-friendly water-based flat coating system, including the following components by mass: 19.5 parts of water, 20 parts of recycled premix for water-based colorful paint, 15 parts of film formers, 0.5 parts of thickening system, 3 parts of additives, and 36 parts of pigments and fillers .

[0041] The thickening system in the water-based flat coating system has the following components in parts by mass: 0.3 parts of hydrophobically modified alkali-swellable thickener; 0-0.3 parts of hydroxyethyl cellulose; 0-0.2 parts of polyurethane thickener;

[0042] The auxiliary agent in the water-based flat coating system includes the following components in parts by mass: 1 part of propylene glycol, 1 part of alcohol fat, 0.1 part of nonionic alkylphenol polyoxyethylene ether, 0.6 part of sodium polyacrylic acid; mineral oil defoamer 0.1 part; 0.1 part of PH regulator (amine multifunctional additive), 0.3 part of preservative;

[0043] The pigments and filler...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com