Milk-flavor wolfberry liqueur and preparation method thereof

A technology of liqueur and wolfberry, applied in the field of food processing, can solve the problems of poor quality, deterioration of quality, failure to achieve nutrition and health care, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

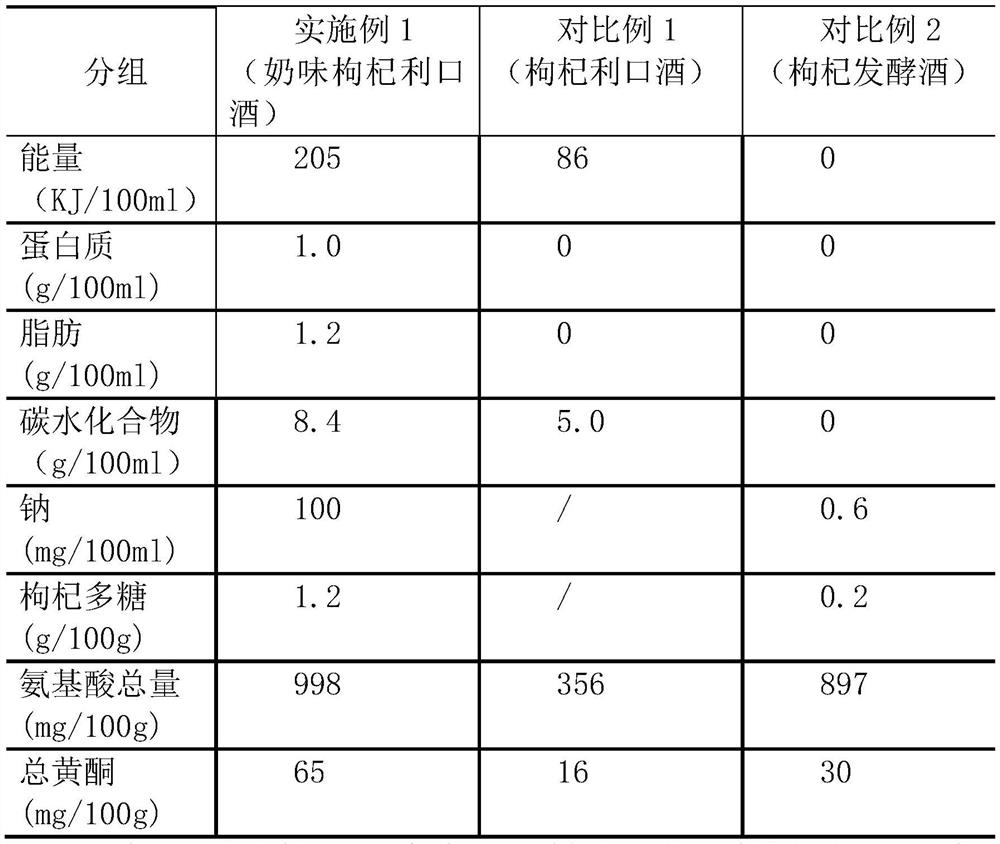

Examples

preparation example Construction

[0038] One embodiment of the present invention proposes a preparation method of milk-flavored wolfberry liqueur, comprising the following steps:

[0039] (1) cleaning the fresh wolfberry fruit, beating, and centrifuging to obtain wolfberry clear juice and wolfberry pulp;

[0040] (2) inoculating yeast to the clear juice of wolfberry obtained in step (1), fermenting to obtain fermented wolfberry wine, and then performing two distillations to obtain distilled wolfberry wine, so that the nutritional components in the wolfberry fruit juice are completely retained in the wolfberry wine;

[0041] (3) Vacuum freeze-drying the wolfberry pulp obtained in step (1), and then superfine grinding to obtain a wolfberry freeze-dried powder, so that the nutrients in the wolfberry pulp and pericarp are completely retained in the ingredient wolfberry freeze-dried powder, avoiding the traditional wolfberry wine Nutrient loss resulting from the separation of lees after fermentation or maceration; ...

Embodiment 1

[0062] The preparation of embodiment 1 milk-flavored wolfberry liqueur

[0063] (1) Pick 2100kg of fresh wolfberry fruit that meets the requirements, wash it with pure water and transfer it to a double-channel beater for beating. After removing the wolfberry seeds, it is centrifuged in a tubular centrifuge to obtain 1416kg of wolfberry clear juice and 672kg of wolfberry pulp;

[0064] (2) Add 1416kg of wolfberry clear juice obtained in step (1) to 243g of Saccharomyces cerevisiae for fermentation. The fermentation temperature is 25°C. When the sugar content of the fermentation liquid is ≤10g / L, the fermentation can be stopped to obtain fermented wolfberry wine. Use a red copper still Carry out two distillations, the temperature of the first distillation is 85-90°C, when the alcohol content of the distillate is ≤0.5% Vol, stop the distillation, the second distillation temperature is 80°C-85°C, and the alcohol content >70% Vol Distilled wine head and distilled wine tail with al...

Embodiment 2

[0068] The preparation of embodiment 2 milk-flavored wolfberry liqueur

[0069] (1) Pick 1800kg of fresh wolfberry fruit that meets the requirements, wash it with pure water and transfer it to a double-channel beater for beating. After removing the wolfberry seeds, it is centrifuged in a tubular centrifuge to obtain 1100kg of wolfberry clear juice and 360kg of wolfberry pulp;

[0070] (2) Add 1100kg of wolfberry clear juice obtained in step (1) to 220g of Saccharomyces cerevisiae for fermentation. The fermentation temperature is 25°C. When the sugar content of the fermentation liquid is ≤10g / L, the fermentation can be stopped to obtain fermented wolfberry wine. Use a red copper still Carry out two distillations, the temperature of the first distillation is 85-90°C, when the alcohol content of the distillate is ≤0.5% Vol, stop the distillation, the second distillation temperature is 80°C-85°C, and the alcohol content >70% Vol Distilled wine head and distilled wine tail with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com