High-concentration organic waste liquid plasma cracking and recombining system and method

A technology of organic waste liquid and plasma, applied in combustion methods, lighting and heating equipment, combustion types, etc., can solve the problems of insufficient safety, incomplete treatment, and insufficient incineration area, so as to reduce treatment costs and improve purification. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

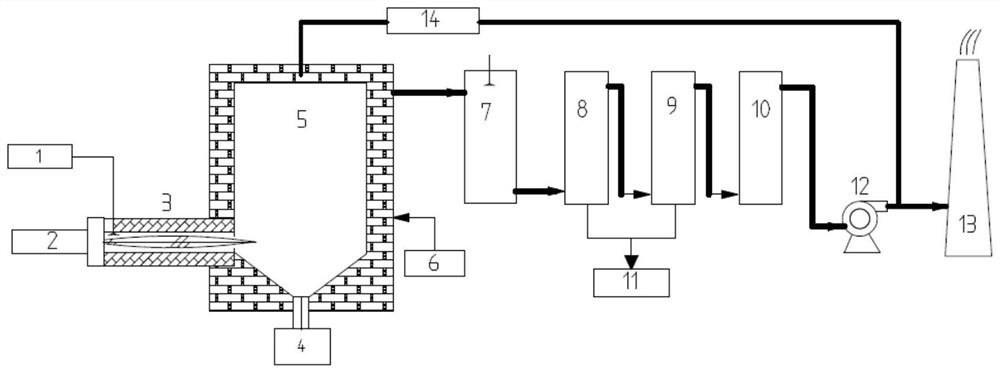

[0032] The plasma cracking recombination method of fluorine-containing organic waste liquid comprises the following steps:

[0033] Step 1. The plasma torch 2 is ignited and preheated, and the temperature of the cracking zone 3 reaches 800-1000° C.; the additive can be borosilicate. The heating operation can be performed in a plasma melting furnace, and the slag collection can be completed through the ash collector 4, which is common knowledge of those skilled in the art.

[0034] Step 2. The fluorine-containing organic waste liquid is pumped to the atomizing head in the waste liquid storage tank 1. A heater can be installed in the middle of the pipeline to heat the waste liquid to 80-100°C; the droplets ejected from the atomizing head are directly Entering the plasma arc area (i.e. cracking zone 3), the cracking produces CO, C m Hn, HF gas;

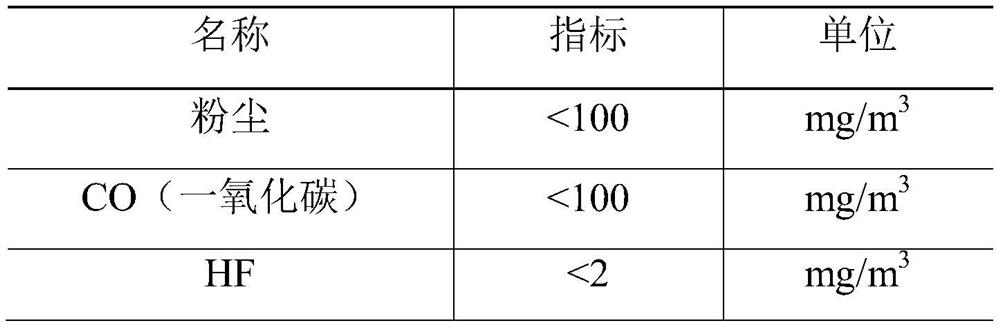

[0035] Step 3. Mix the CO, CmHn, and HF gases described in step 2 with air in a mixing volume ratio of 1.5:1 to 1:1; burn in the refo...

Embodiment 2

[0049] Such as figure 1 As shown, the difference between this embodiment and embodiment 1 is:

[0050] (1) In step 2, the fluorine-containing organic waste liquid is mixed with compressed air and sprayed into the plasma arc to improve the atomization effect;

[0051] (2) Water vapor is mixed into the working gas of the plasma torch to provide the active hydrogen ions and oxygen ions required for the cracking of fluorine-containing organic waste liquid, and completely convert the fluorine in the waste liquid into hydrogen fluoride.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com