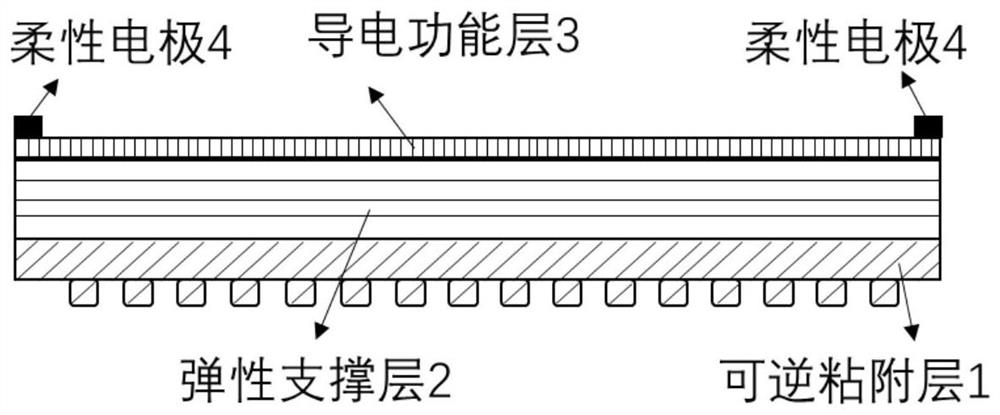

Electronic skin capable of quickly and reversibly adhering and deadhering as well as preparation method and application of electronic skin

An electronic skin and fast technology, applied in the field of human body wearable sensing materials, can solve the problems of non-adhesion and poor fit of the skin, achieve synchronous movement and deformation, excellent stretch and resilience, and realize physical infiltration and adhesion attached effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] 1) Casting an epoxy resin matrix with shape memory function (glass transition temperature at 37°C) into a silicon wafer mold with an array of micro-pillar grooves, wherein the linear density of the micro-pillar grooves is 0.1 μm -1 , with a diameter of 10 μm and a depth of 5 μm, vacuuming and defoaming so that the shape-memory epoxy resin completely fills the groove, and the thickness of the shape-memory polymer is 5 μm higher than the depth of the groove;

[0050] 2) heating the shape-memory epoxy resin at 35° C. for 5 minutes to harden its surface, and using ultraviolet ozone (ultraviolet wavelength 253 nm, energy 472 kJ / mol) to irradiate the surface of the surface-hardening shape-memory epoxy resin for 10 minutes, pouring elastomeric liquid silicone rubber on the surface of the surface-treated shape-memory epoxy resin layer to ensure that the elastomeric liquid silicone rubber is stably present on the upper layer of the shape-memory epoxy resin;

[0051] 3) further h...

Embodiment 2

[0055] 1) Casting a polyurethane matrix with shape memory function (glass transition temperature at 37°C) into a silicon wafer mold with an array of micro-columnar grooves, where the linear density of the micro-cylindrical grooves is 1 μm -1 , with a diameter of 1 μm and a depth of 10 μm, vacuuming and defoaming so that the shape-memory polyurethane completely fills the groove, and the thickness of the shape-memory polymer is 100 μm higher than the depth of the groove;

[0056] 2) Heating the shape-memory polyurethane at 35°C for 5 minutes to harden its surface, using plasma (power 36W) to perform surface treatment on the surface-hardened shape-memory polyurethane for 10 minutes, and pouring a thermoplastic elastomer polyurethane solution on the The surface of the surface-treated shape-memory polyurethane layer ensures that the thermoplastic elastomer polyurethane solution exists stably on the upper layer of the shape-memory polyurethane;

[0057] 3) further heating at 35° C. ...

Embodiment 3

[0061] 1) The liquid crystal elastomer (glass transition temperature: 45°C) matrix with shape memory function is cast into a polytetrafluoroethylene mold with a micro-columnar groove array, wherein the linear density of the micro-cylindrical grooves is 0.1 μm -1 , with a diameter of 10 μm and a depth of 10 μm, vacuumizing and defoaming so that the shape-memory liquid crystal elastomer completely fills the groove, and the thickness of the shape-memory polymer is 290 μm higher than the depth of the groove;

[0062] 2) Heating the shape-memory liquid crystal elastomer at 30°C for 5 minutes to harden its surface, using ultraviolet ozone (ultraviolet wavelength 253nm, energy 472kJ / mol) to irradiate the surface of the surface-hardened shape-memory liquid crystal elastomer for 10 minutes, and Elastomer liquid natural rubber latex is poured on the surface of the surface-treated shape-memory liquid crystal elastomer layer to ensure that the elastomer liquid natural rubber is stably pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com