Preparation method and medical application of extract of monkshood reduced total alkali

An extract, the technology of Aconitum aconitum, applied in the field of extract preparation of Aconitum aconitum reduced total alkaloids, can solve the problems of poor druggability and small safety window of treatment, etc., and achieve the effect of low production cost, simple method and high alkaloid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

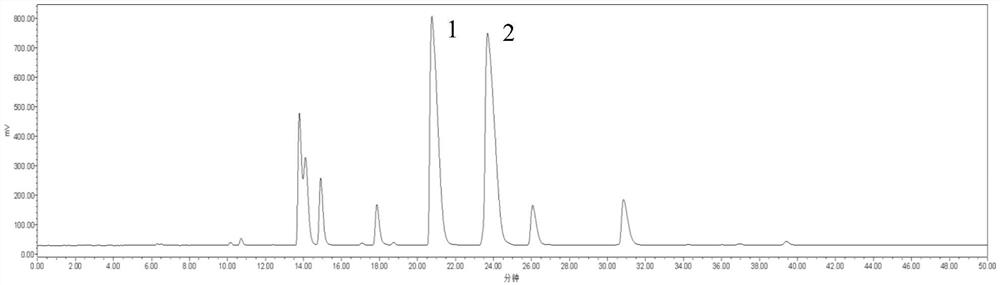

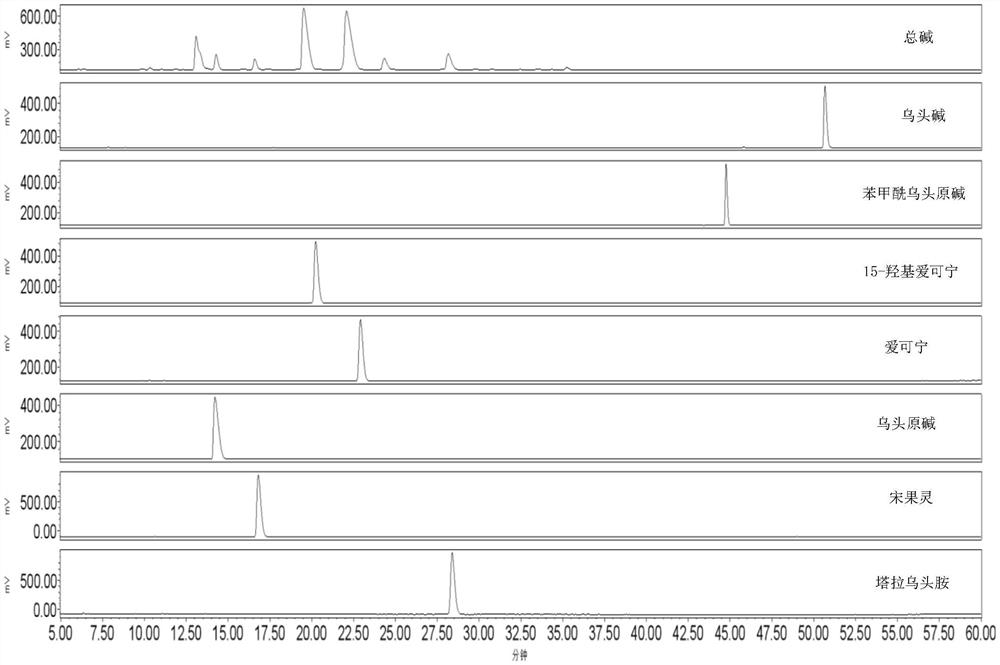

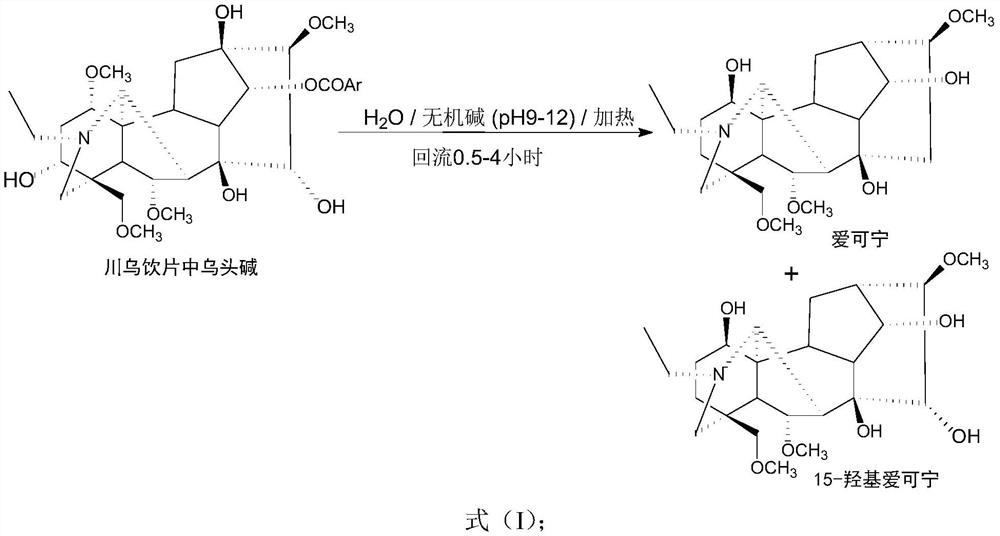

Embodiment 1

[0027] Cut the fresh roots of Aconiti officinalis into slices, 3 parts of fresh Aconitum aconitum slices, 0.05 parts of calcium hydroxide, add 8 parts of water to the first extraction, add to a frying pan, heat at 100°C for 60 minutes, and keep the medicinal liquid in alkaline pH9- 12. Filter out the medicinal liquid; add 7 parts of water to the second extraction, heat at 100°C for 30 minutes, filter out the medicinal liquid, combine the decoction, let stand for 6 hours, cool to 40-50°C, filter the supernatant, and flow the filtrate through the pre- The chromatographic column of the processed non-polar macroporous resin, the resin model is AB-8, the dosage is 0.5 times the amount of medicinal materials fed, and the flow rate is 0.1 times the resin volume / min. After completely flowing through the adsorption, wash with deionized water Remove the resin column, the elution volume is 8 times the volume of the resin, then elute the resin column with 15% ethanol, the elution volume of...

Embodiment 2

[0029] 1 part of aconite slices, 0.05 parts of sodium carbonate, add 10 parts of water for the first extraction, add to a frying pan, heat at 100°C for 60 minutes, keep the medicinal liquid at an alkaline pH9-10 during the extraction process, and filter out the medicinal liquid; extract the water for the second time Add 7 parts, heat at 100°C for 30min, filter out the medicinal solution, combine the decoction, let it stand for 6 hours, cool to 40-50°C, filter the supernatant, and the filtrate flows through the layer of pretreated non-polar macroporous resin Analysis column, the resin model is D101, the dosage is 0.5 times of the amount of medicinal materials fed, and the flow rate is 0.2 times of the resin volume / min. After completely flowing through the adsorption, the resin column is eluted with deionized water, and the elution volume is 4 times of the resin volume. Then elute the resin column with 15% ethanol, the eluting volume of alcohol solution is 4 times of the resin vo...

Embodiment 3

[0031] Get the total reducing bases of Aconitum in Example 1 and the total reducing bases of Aconite in Example 2, and be configured into a solution containing 7 mg / ml of total reducing bases of Aconitum and 7.5 mg / ml of total reducing bases of Aconitum respectively, and additionally prepare into a solution containing aconitine 0.01mg / ml; get 30 mice with a body weight of 20g, divide them into three groups, 10 in each group, and administer the above-mentioned aconitine total reducing bases, aconitum total reducing bases, aconitum total reducing bases, and Each 1ml of the head alkali solution / animal, observed the number of dead animals, and the experimental results are shown in Table 1. The results show that the toxicity of total reducing bases of aconitum is similar to that of total reducing bases of aconitum, and the toxicity of aconitine is more than 700 times lower than that of aconitine.

[0032] Table 1

[0033] group Number of mice administered in each group...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com