Seawater desulfurization process and system for ship flue gas with high specific surface area

A high specific surface area, desulfurization process technology, applied in the high specific surface area ship flue gas seawater desulfurization process and system field, can solve the problems of poor desulfurization effect, complex desulfurization methods, large volume of desulfurization equipment, etc., achieve good wettability, reduce ship Space, reduced area and volume effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

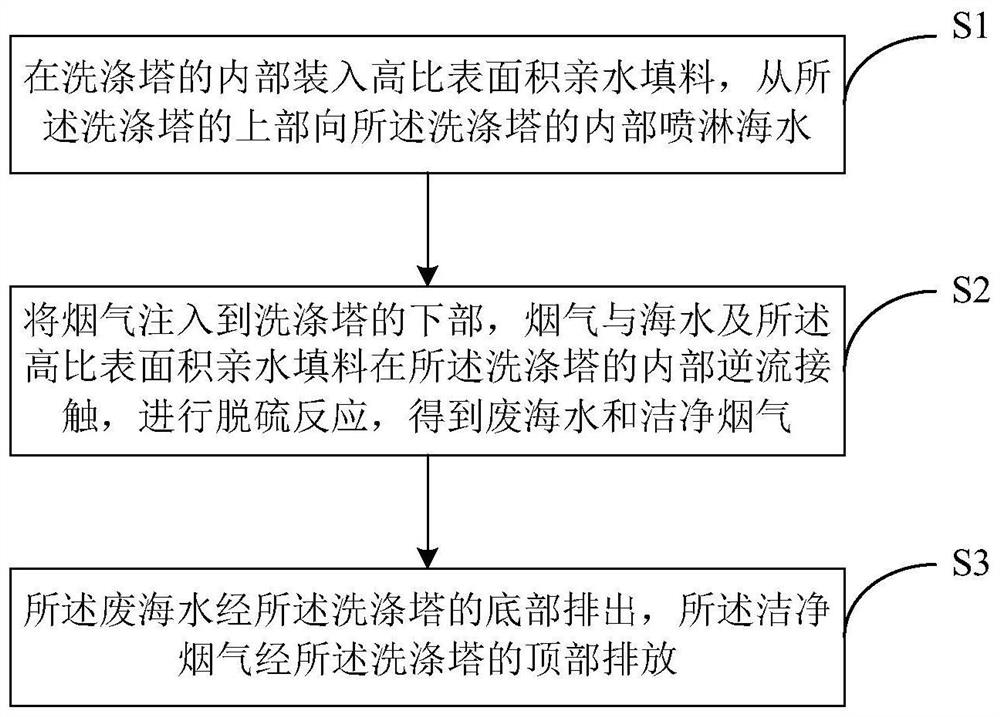

[0029] see figure 1 , is a schematic flow diagram of a high specific surface area ship flue gas seawater desulfurization process provided by an embodiment of the present application. For the convenience of description, only the parts related to this embodiment are shown, and the details are as follows:

[0030] In one of the embodiments, the first aspect of the present application provides a high specific surface area ship flue gas seawater desulfurization process, which is used to desulfurize the flue gas discharged from sulfur-containing marine diesel engines, including the following steps:

[0031] S1. Fill the inside of the washing tower with a high specific surface area hydrophilic filler, and spray seawater from the upper part of the washing tower to the inside of the washing tower.

[0032] Specifically, the interior of the washing tower is equipped with a supported hydrophilic catalyst TiO 2 -Al 2 o 3 Hydrophilic structured packing with high specific surface area, t...

Embodiment 2

[0042] All the other are identical with embodiment 1, and difference is: fixed seawater spraying amount is 25m 3 / h, the corresponding liquid-gas ratio is 6.4L / Nm3, by changing the operating temperature of the seawater scrubber, test the pressure drop of the scrubber bed layer and the removal of SO from the flue gas of seawater marine diesel engine 2 The reaction results are shown in Table 2.

[0043] Table 2 Scrubber pressure drop and seawater SO removal 2 removal rate

[0044] Experiment number temperature(℃) Washing tower pressure drop (Pa) SO 2 Removal rate (%)

[0045] It can be seen that the desulfurization rate of seawater with high specific surface area hydrophilic structured catalytic packing can reach 99% at different temperatures, and the desulfurization effect is remarkable. At the same time, the pressure drop of the bed layer of the scrubber is also very low, only about 200Pa, which will not affect the flue gas discharged from the ship's flue g...

Embodiment 3

[0047] The rest are the same as in Example 2, the difference is that by changing the packing volume of the high specific surface area hydrophilic structured catalytic packing, the volumes are respectively 0.3m 3 、0.4m 3 、0.5m 3 and 0.6m 3 , corresponding to the airspeed of 12920h -1 、9690h -1 、7752h -1 and 6460h -1 , to test the removal of SO from marine diesel engine flue gas by seawater 2 The reaction results are shown in Table 3.

[0048] Table 3 High specific surface area hydrophilic structured catalytic packing packing volume and seawater SO removal 2 removal rate

[0049] Experiment number Filling volume (m 3 )

Acid seawater cleaning time (h -1 )

SO 2 Removal rate (%)

1 0.3 12920 92 2 0.4 9690 99 3 0.5 7752 99 4 0.6 6460 99

[0050] It can be seen that with the increase of acid seawater cleaning time, the desulfurization rate decreased.

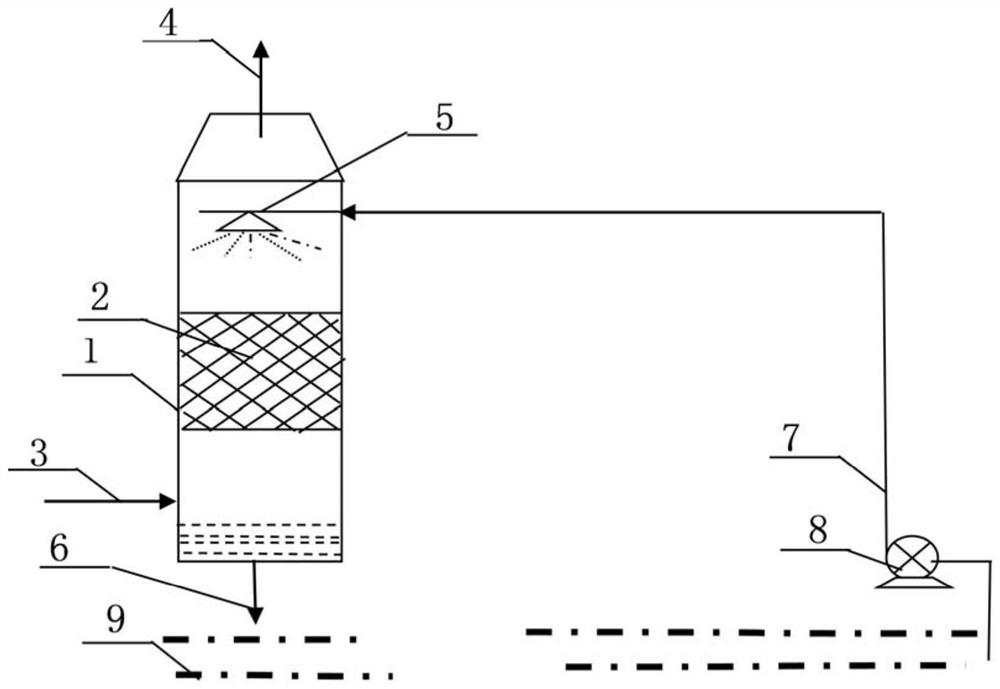

[0051] see figure 2 , is a structural schematic diagram of a h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Wave distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com