Tablet press rotating disc drilling method and concentric positioning device applied to method

A drilling method and concentric positioning technology, which are used in positioning devices, boring/drilling, drilling/drilling equipment, etc., can solve the problem of low efficiency in manually drawing lines to find the center of the circle, high labor intensity of staff, and reduced product production. efficiency and other issues, to achieve the effect of convenient and quick disassembly and assembly, ingenious structural design, and reduced labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

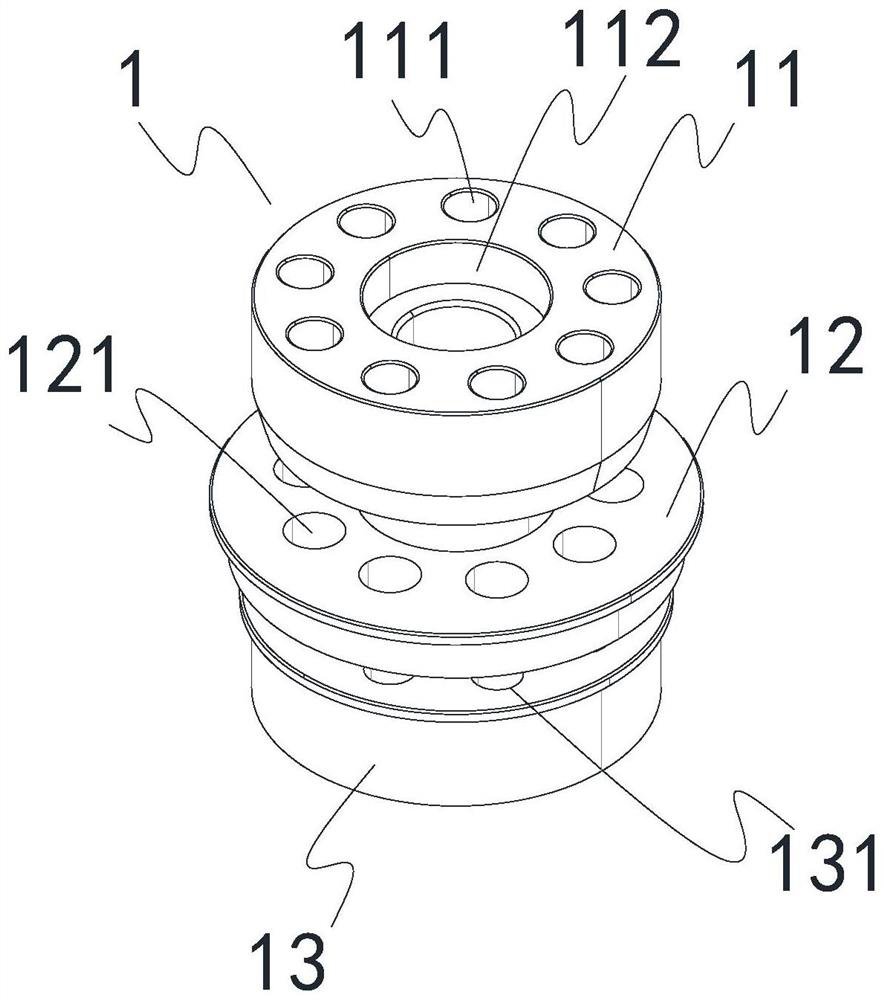

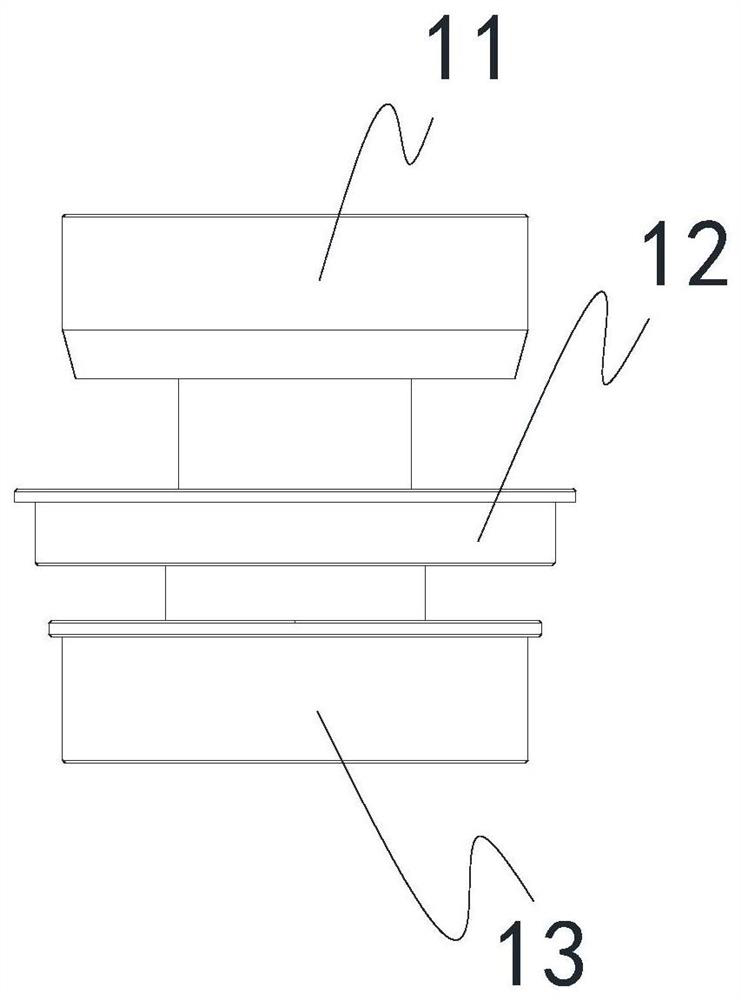

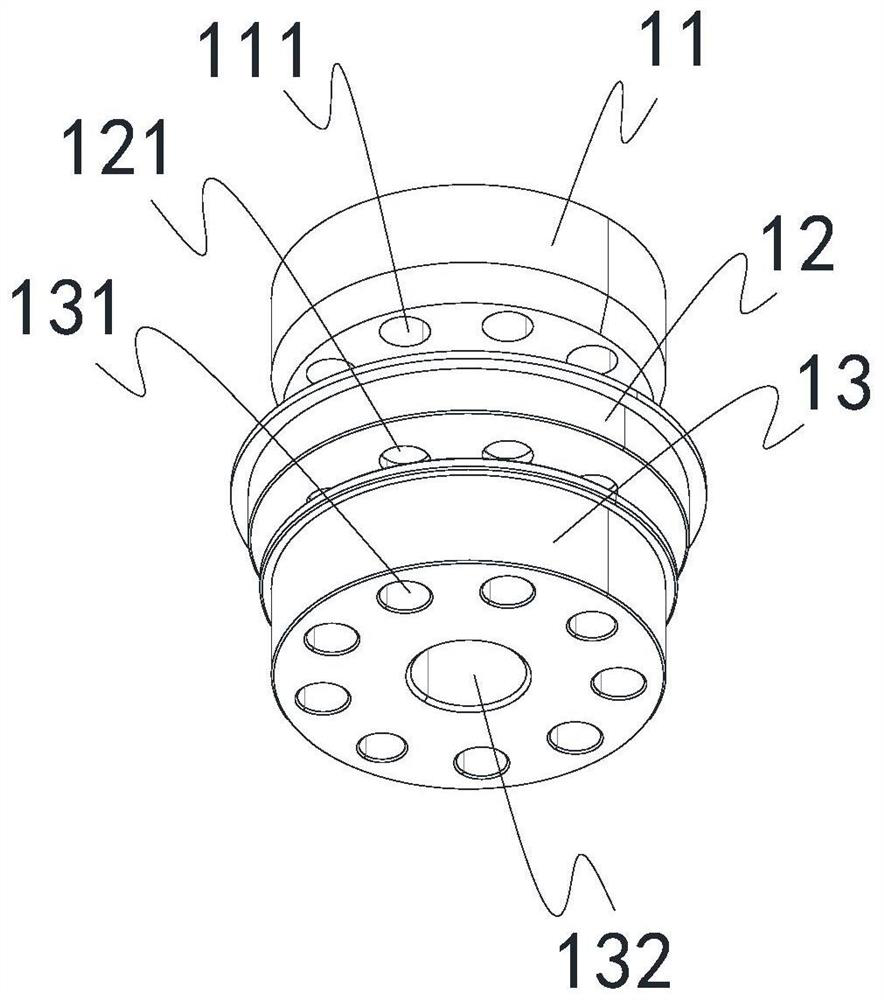

[0072] A method for drilling a turntable of a tablet press, wherein the isocircular through holes on the turntable 1 of the tablet press include the following processing steps:

[0073] a. The lower hole reference plate 23 is prepared in advance, and the middle position of the lower hole reference plate 23 is fixed with a connecting rod 22; the lower hole reference plate 23 is pre-opened with a lower substrate through hole 231 corresponding to the equal circular through hole C131;

[0074] b. Set the turntable to be drilled on the connecting rod 22, and the turntable to be drilled after being inserted has no degree of freedom in the horizontal direction;

[0075] c. Cover the upper hole reference plate, and the upper base plate through-hole corresponding to the isocircular through hole A is pre-opened on the upper hole reference plate. When placing the upper hole reference plate, it is necessary to align the upper base plate through hole The through holes of the lower substrat...

Embodiment 2

[0085] This embodiment is based on embodiment 1. The assembly in step e of embodiment 1 is fixed on the workbench 33 of the drilling machine 3 through the index plate 5 with the claw 51, and the claw 51 on the index plate 5 is locked. The lower hole reference plate 23 is tightened, and the chassis 52 of the index plate 5 is fixed on the workbench 33 of the drilling machine 3 by bolts. The assembly is placed on the claws, the claw screw is adjusted to lock the assembly, and the crank handle of the indexing plate is turned to adjust the rotation angle of the assembly. The indexing plate with claws is the prior art. The claws are used to fix the assembly on the workbench, and the indexing plate is used to adjust the rotation angle of the assembly. The operation is simple and convenient, and the time for the drill bit to align with the center of the circle can be shortened ,Shorten the production cycle.

[0086] The disassembly method of the reamer relative to the knife handle in...

Embodiment 3

[0088] This embodiment is a concentric positioning device applied in the above-mentioned rotary table drilling method of the tablet press, which mainly includes an upper hole reference plate 21 and a lower hole reference plate 23;

[0089] The upper hole reference plate 21 is provided with upper substrate through holes 211 corresponding to the isocircular through holes A111 in the circumferential direction, and each upper substrate through hole 211 is embedded with a hollow protective sleeve 212, and the hollow protective sleeve 212 The inner diameter is equal to the diameter of the equal-circle through hole A111; the back of the upper hole reference plate 21 is provided with a positioning protrusion 213 that matches the opening 112 of the upper die of the turntable;

[0090] The lower hole reference plate 23 is provided with a lower substrate through hole 231 corresponding to the isocircular through hole C131 in the circumferential direction, and the middle position of the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com