Fire-proof and explosion-proof blanket and preparation method thereof

A technology of explosion-proof layer and waterproof layer, which is applied in the direction of chemical instruments and methods, coatings, layered products, etc., and can solve the problems that the fire blanket has no explosion-proof protection, affects the safety performance of wires and cables, and is damaged

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0062] like Image 6 Shown, a kind of preparation method of fireproof explosion-proof blanket, it comprises:

[0063] S1, forming a composite fireproof film;

[0064] S2. Stitching the composite fireproof film to form multiple cavities;

[0065] S3, filling heat-insulating fillers in the plurality of cavities to form a fire-proof and heat-insulating intermediate;

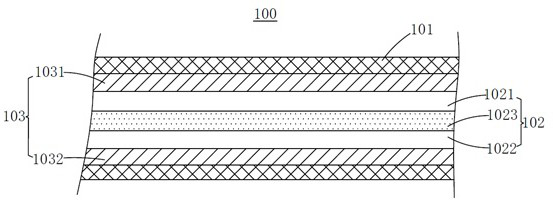

[0066] S4. Coating an explosion-proof layer on the outside of the fire-proof and heat-insulating intermediate;

[0067] S5. Coating a flame-retardant and waterproof layer on the outside of the explosion-proof layer to prepare a fire-proof and explosion-proof blanket.

[0068] In a preferred embodiment, in the step S1, the flame retardant silicone rubber and the glass fiber woven cloth are compounded to form a composite fireproof film through a calendering process or a molding process.

[0069] In S2, it includes cutting the composite fireproof film; folding the cut composite fireproof film in half, or providing ...

Embodiment 1

[0074] 1) Coating flame-retardant silicone rubber with a flame-retardant grade of V0 (purchased from Shenzhen Zhengan Organic Silicon Material Co., Ltd.) on one side of the glass fiber woven cloth through a calendering process to prepare a composite fire-resistant film; wherein, the calendering process The temperature is 180℃±5℃; the rolling speed is 20m / min; the thickness of the formed composite fireproof film is 0.5mm;

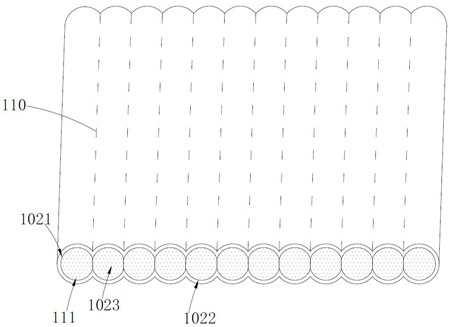

[0075] 2) Cut the calendered composite fireproof film on the platform to a rectangle with a size of 1000mm*800mm, then sew the upper and lower layers of composite fireproof film with nylon flame retardant thread, and after sewing, the gap between the two layers of composite fireproof film The cross-sectional shape of the cavity is triangular;

[0076] 3) Mix magnesium hydroxide and aluminum oxide in proportion to form thermal insulation filler, fill the thermal insulation filler into the above cavity, and then sew the opening of the cavity for edge sealing t...

Embodiment 2

[0081] 1) Coating flame-retardant silicone rubber with a flame-retardant grade of V0 (purchased from Shenzhen Zhengan Organic Silicon Material Co., Ltd.) on the surface of one side of the glass fiber woven cloth through a molding process to prepare a composite fire-resistant film, the temperature of the molding process The temperature is 200℃±5℃, and the thickness of the composite fireproof film is 0.8mm;

[0082] 2) Cut the molded composite fireproof film into two pieces on the platform, cut a rectangle with a size of 1000mm * 850mm, and then sew the upper and lower layers of composite sheets with nylon flame-retardant thread, and then composite the fireproof film The cross-sectional shape of the cavity between them is circular;

[0083] 3) Mix mica powder and silicon bath soil in proportion to form thermal insulation filler, fill the thermal insulation filler into the above cavity, and then sew the opening of the cavity for edge sealing to form a fireproof and thermal insula...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com