Gas stripping double circulation-continuous flow granular sludge reactor and method for treating sewage by adopting reactor

A granular sludge and reactor technology, applied in water/sludge/sewage treatment, sustainable biological treatment, chemical instruments and methods, etc., can solve the problem of continuous flow reactors that are difficult to maintain long-term stable operation, low volume utilization, Solve problems such as low equipment utilization, achieve the effect of promoting the maintenance of structural stability, high processing efficiency, and high equipment utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

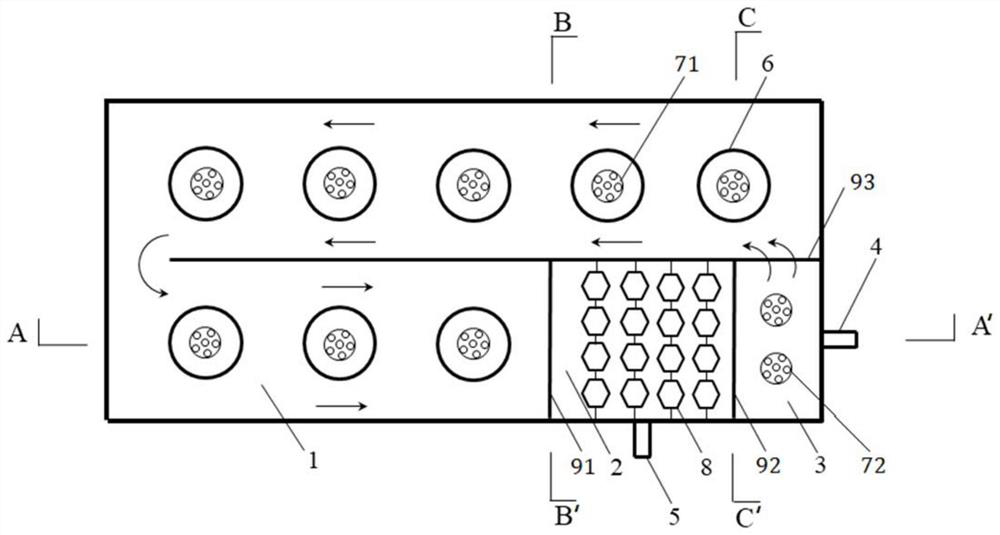

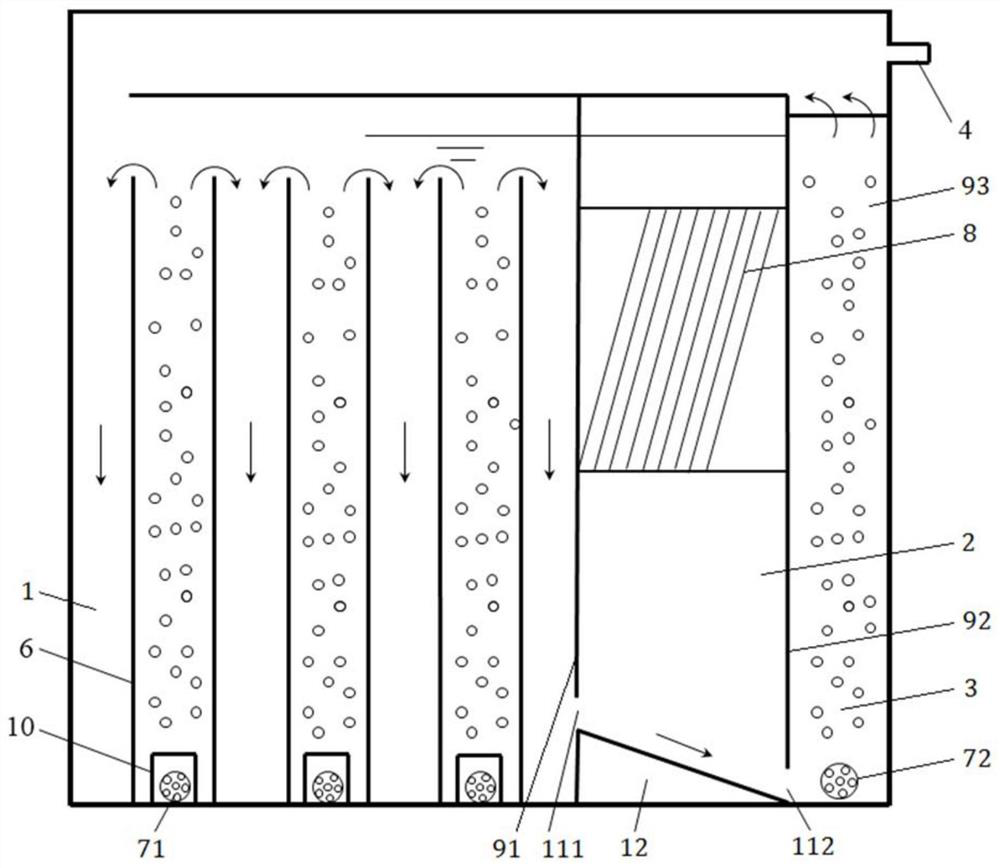

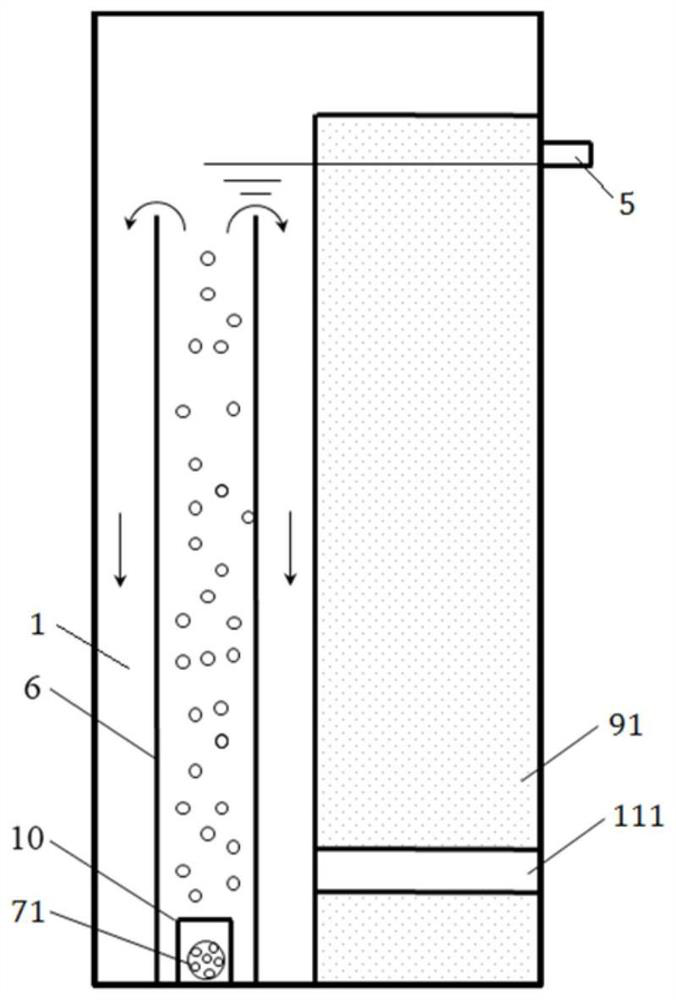

[0063]Set up 5 groups of air-lifting double-circulation-continuous flow granular sludge reactors with the same structure, among them, the air-lifting aeration tank is arranged with 6 aeration tubes, and each aeration tube is randomly opened with 4 to 8 openings, and the aeration The height to inner diameter ratio of the trachea is 35:6; and the upper part of the sedimentation tank is provided with an inclined pipe with an angle of 60° to the horizontal plane, and the bottom is provided with a slope with an angle of 30° to the horizontal plane. Synthetic wastewater is used as sewage to be treated, and the water quality is as follows: COD is 500mg / L (the contribution of glucose and sodium acetate to COD is 1:1), ammonia nitrogen is 50mg / L, total phosphorus is 10mg / L, and pH is adjusted by sodium bicarbonate 7.0 to 8.5.

[0064] Fill the reactor with water, and add aerobic granular sludge (0.8-2.0mm in particle size) at the same time until its final concentration in the reactor i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com