Organic solid waste aerobic fermentation conditioner as well as preparation method and use method thereof

A technology for aerobic fermentation and organic solids, which is applied in the field of solid waste recycling, can solve the problems of increasing the cost of aerobic fermentation, large demand for conditioners, and complex components, achieves excellent biological fermentation regulation, and promotes resource circulation. Use, high degree of harmless effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

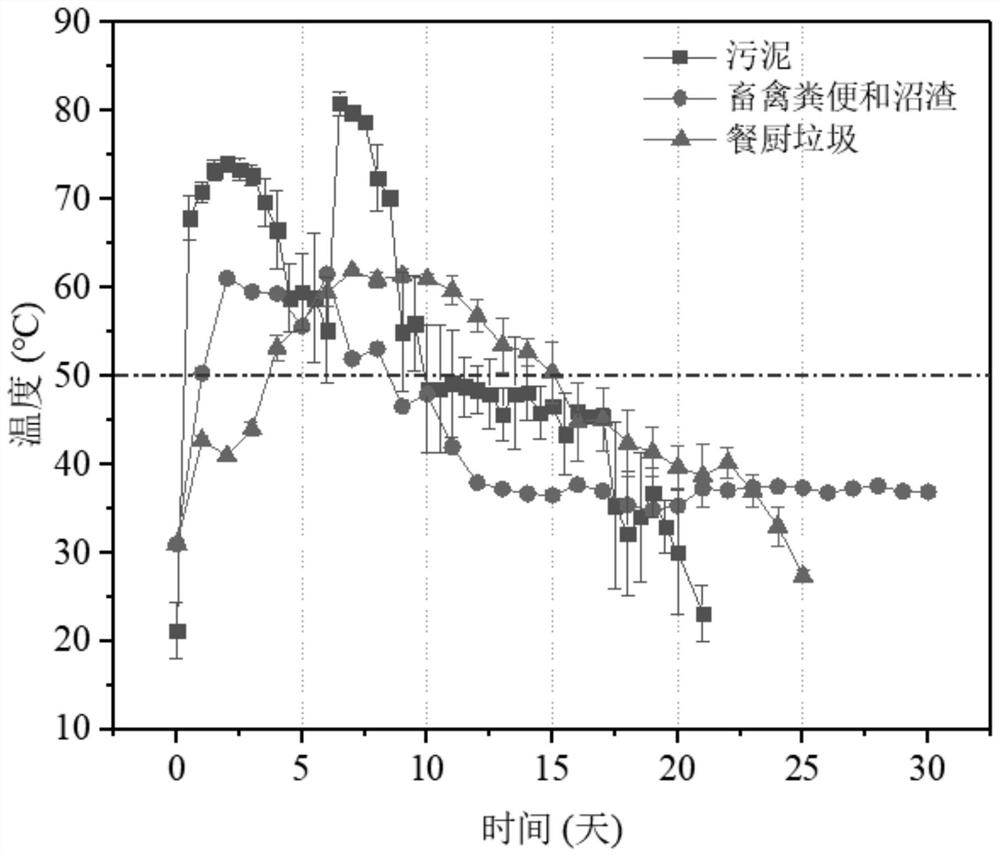

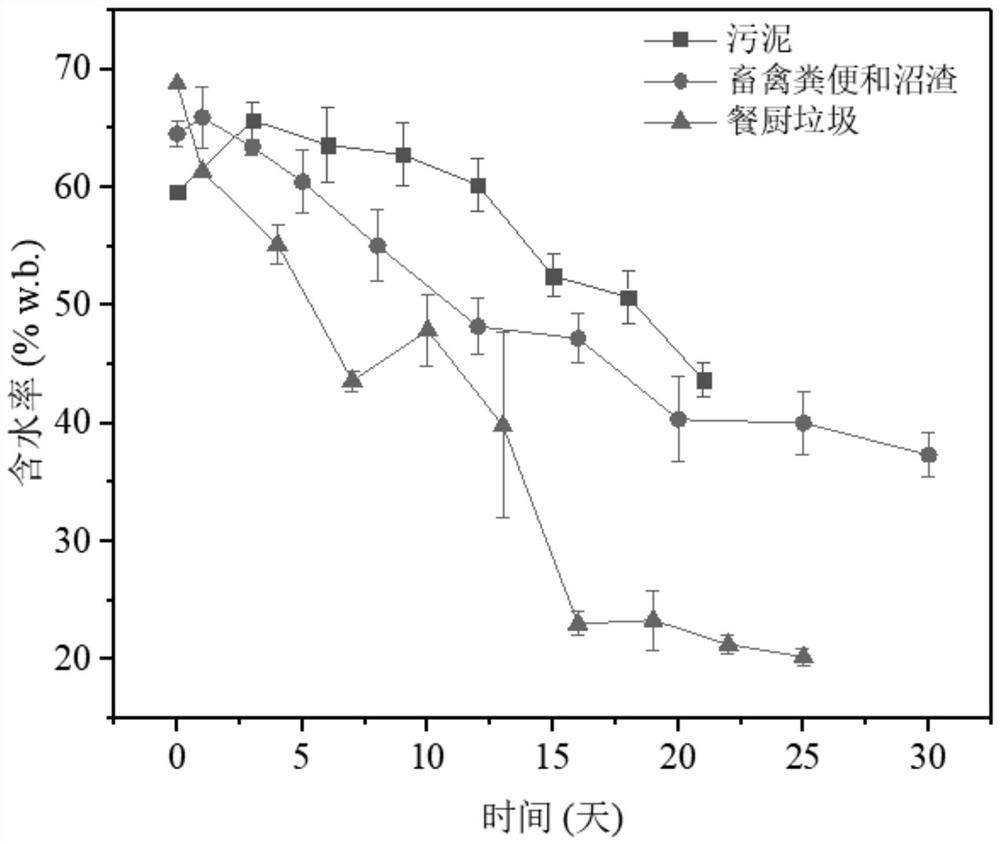

[0043] The present invention will be further described below in conjunction with accompanying drawing.

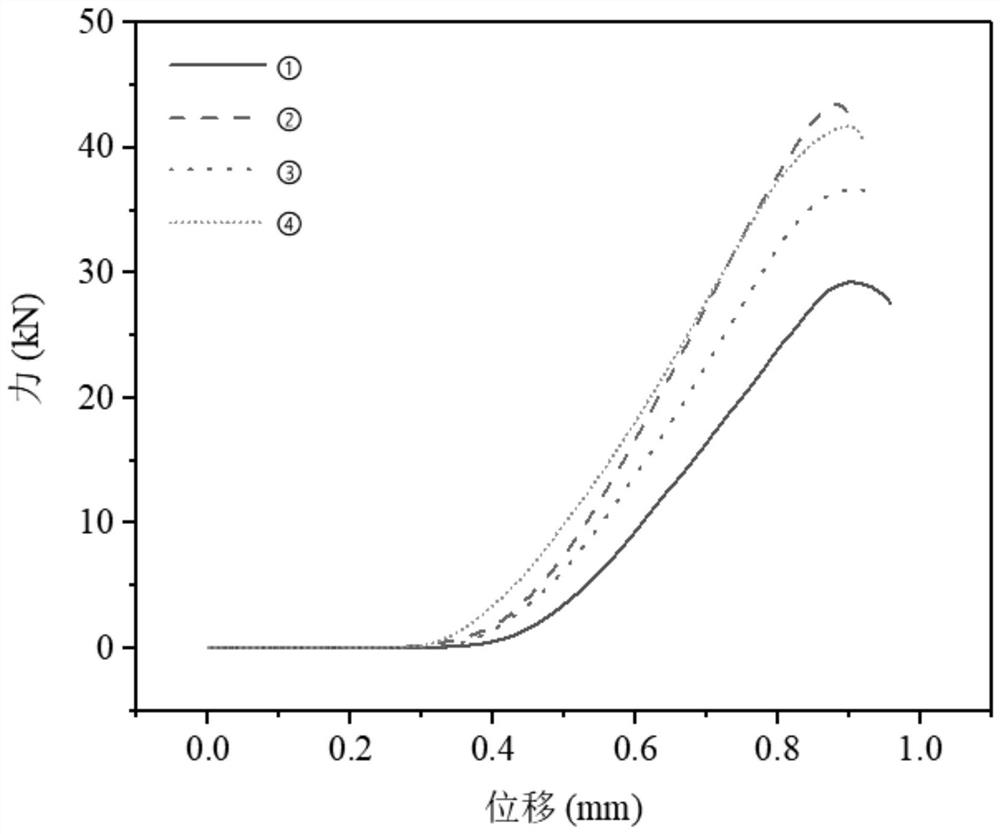

[0044] An organic solid waste aerobic fermentation conditioner of the present invention comprises: cement, pumice, sand, metakaolin and biochar, and the mass fractions of each component are respectively: 27%-31% for cement, and 15% for pumice -25%, sand 43%-50%, metakaolin 2.5%-3.5%, biochar 1.5%-2.5%.

[0045] In one embodiment of the present invention, the cement includes slag portland cement PS52.5.

[0046] In one embodiment of the present invention, the pumice stone includes porous volcanic stone with a diameter of 5-8mm.

[0047] In one embodiment of the present invention, the fineness of the metakaolin is 1250 mesh; the metakaolin is made from kaolin ore through processes such as beneficiation, crushing, grinding and calcination. Highly pozzolanic active material.

[0048] In one embodiment of the present invention, the biochar is high-quality powdered activated c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com