Method for improving heat transfer of gap between pellet and cladding based on graphene aerosol

A graphene and aerosol technology, which is applied in the field of heat transfer in the internal gap of nuclear fuel assemblies, can solve problems such as high thermal resistance, and achieve the effects of improving heat transfer performance, reducing thermal resistance and improving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

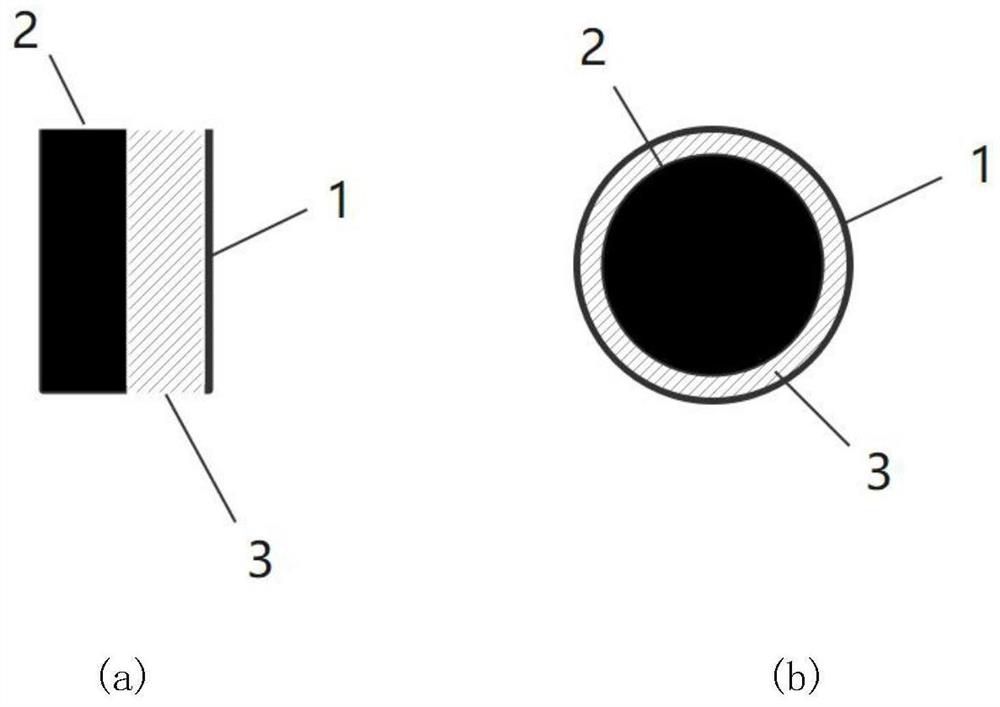

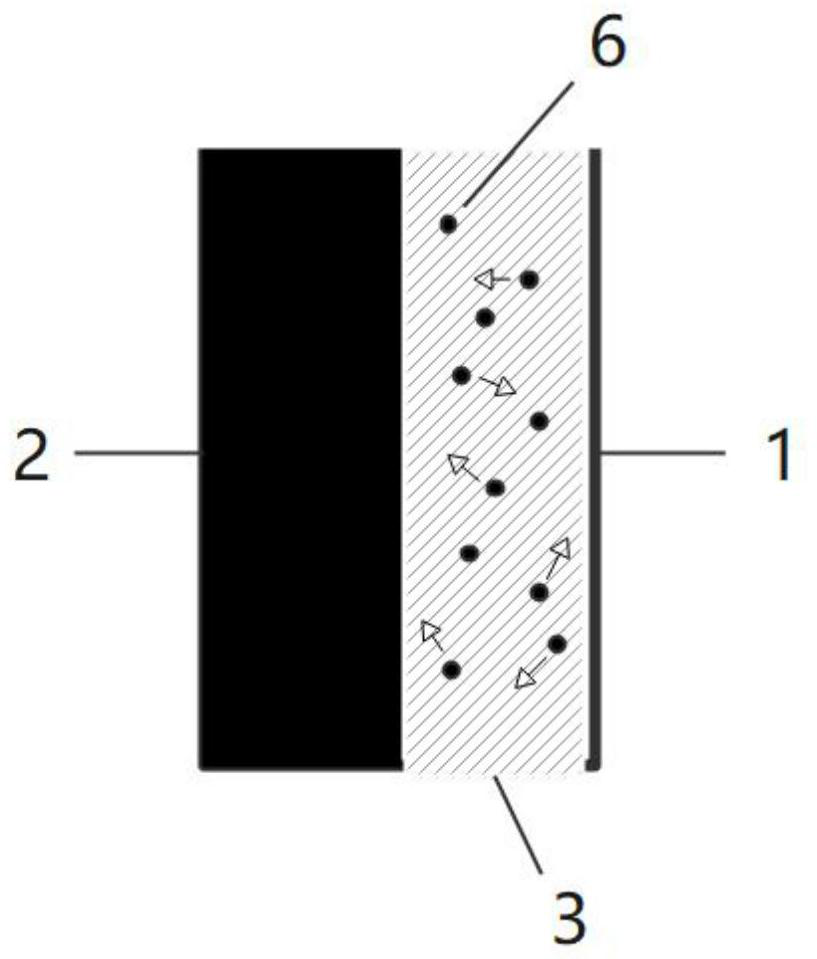

[0043] figure 1 (a) is a schematic diagram of the gap between the core block and the cladding of the present invention; (b) is a top view of the core block and the cladding of the present invention. like figure 1 As shown in (a) and (b), the pellet-cladding gap of the present invention includes a fuel cladding 1 and a fuel pellet 2, the fuel pellet 2 is cylindrical, and the fuel pellet 2 is located inside the fuel cladding 1, The fuel cladding 1 is cylindrical, and an annular gap is formed between the fuel cladding 1 and the fuel pellets 2 , and the annular gap is a helium cavity 3 .

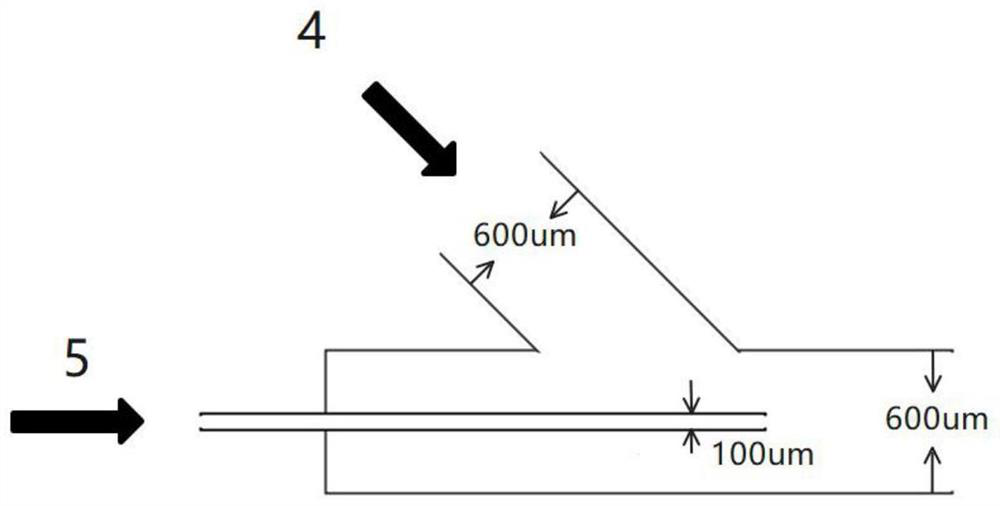

[0044] like figure 2 Shown is a diagram of a capillary microfluidic device for preparing graphene aerosol particles in the present invention. Microfluidic channels are built using microfabrication techniques. The microfluidic channel is composed of a 45° oblique tee capillary and a straight capillary. The oblique tee capillary includes an oblique body and a straight body. Wherein the stra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com