Stripping method for magnetron sputtering in surface acoustic wave filter

A surface acoustic wave and magnetron sputtering technology, applied in the field of microelectronics, can solve the problems of metal film damage, poor temperature resistance, difficult to peel, etc., to achieve good temperature resistance, controllable film thickness, and avoid carbonization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The principles and features of the present invention will be described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0039] The surface acoustic wave filter (SAWF) mainly utilizes its stable frequency source function and filtering function in circuit applications. So frequency is a very important index in SAWF. Moreover, the thickness of the metal film will directly affect the frequency of the SAWF, so the accuracy of the metal film thickness is required to be high.

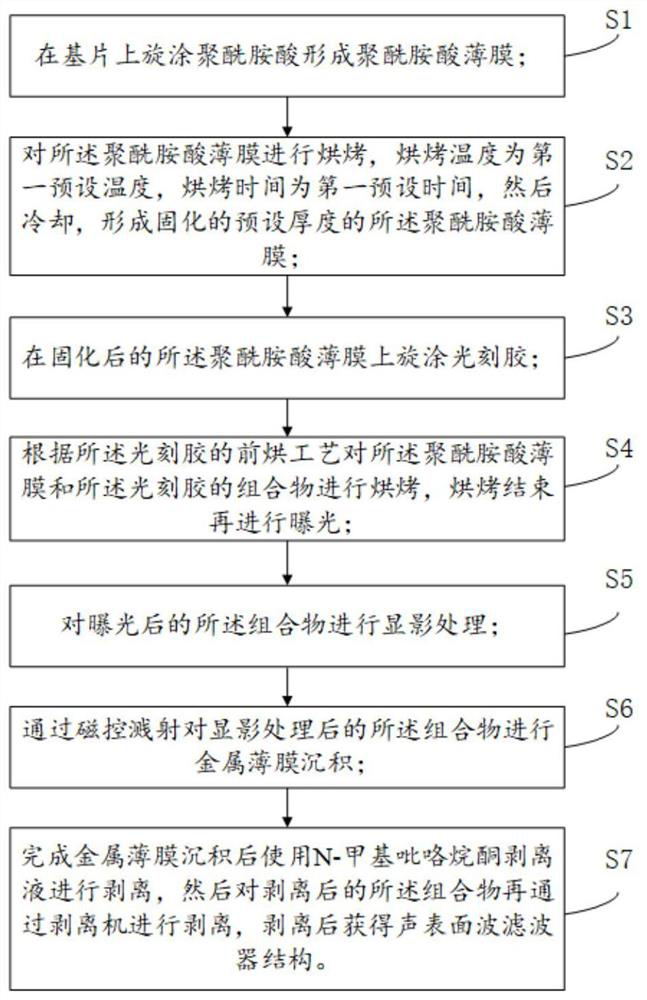

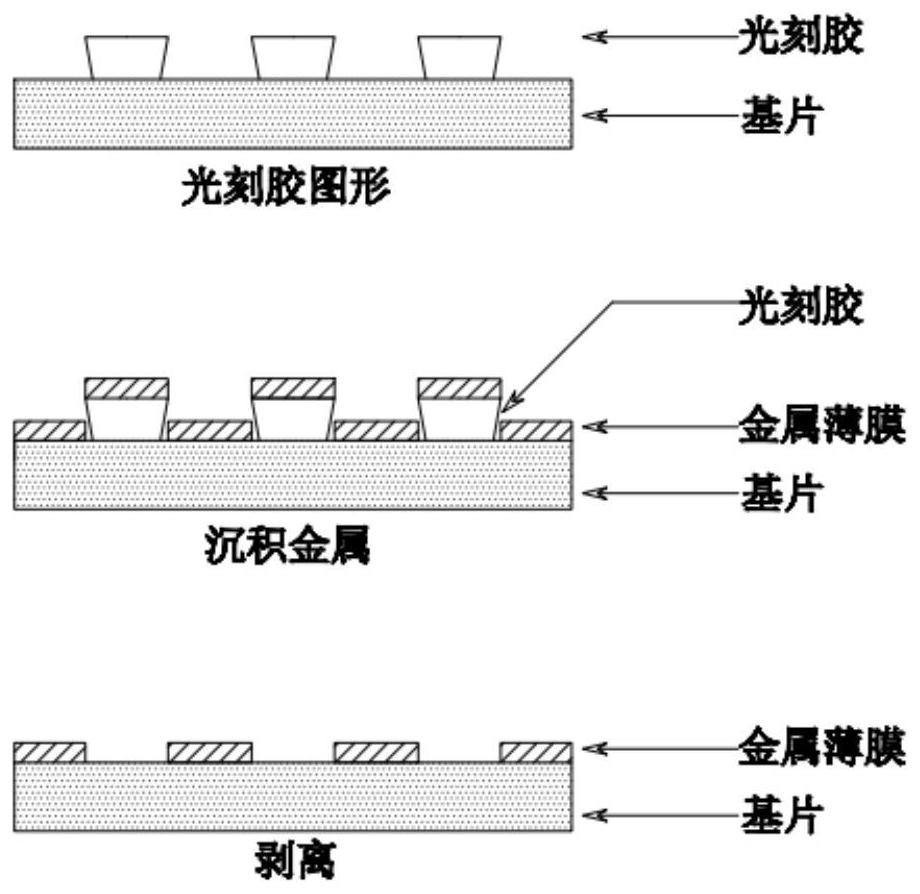

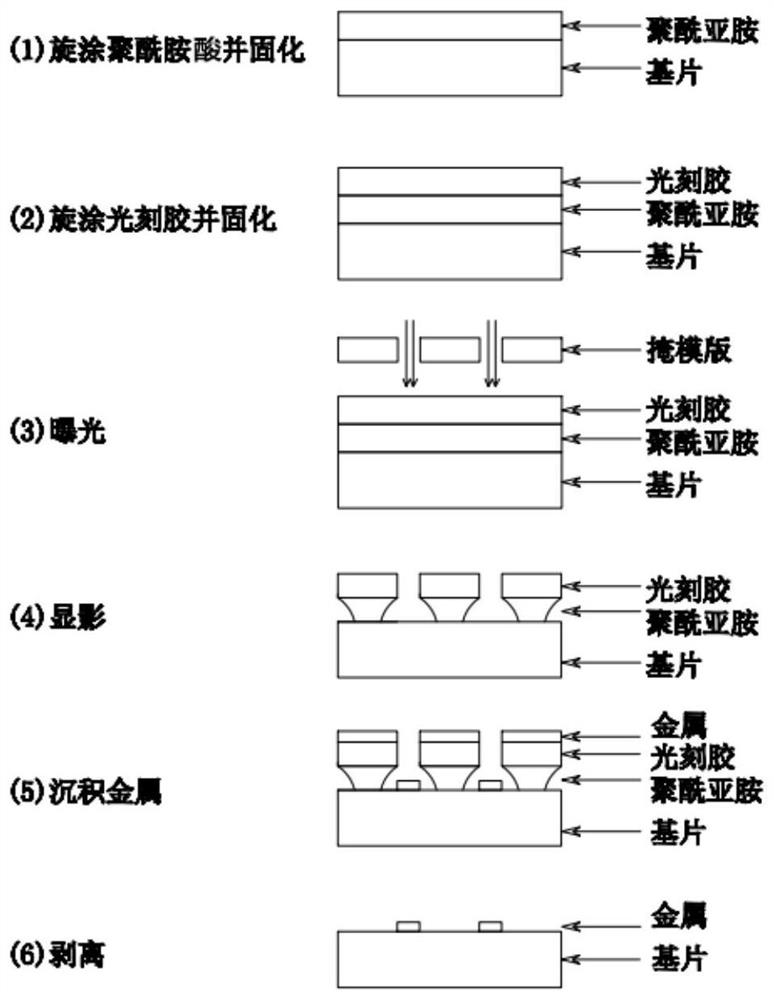

[0040] Such as figure 1 As shown, a stripping method for magnetron sputtering in a surface acoustic wave filter provided by an embodiment of the present invention includes: S1, spin-coating polyamic acid on a substrate to form a polyamic acid film; wherein the spin-coating speed For: 3000-5000 rpm, the concentration of the polyamic acid is: 6%-10%;

[0041] Pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com