Ultramicro rectangular electric connector and production process thereof

A technology for electrical connectors and production processes, applied in the field of ultra-micro rectangular electrical connectors and their production processes, can solve the problems of poor chemical resistance, low mechanical strength of ultra-micro rectangular electrical connectors, and no protective structure, and achieve The effect of convenient fixed installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Such as figure 1 As shown, an ultra-micro-rectangular electrical connector, the ultra-micro-rectangular electrical connector includes a head shell, a mounting plate and a seat shell, and the head shell, the mounting plate, and the seat shell are all made of polyphenylene sulfide resin composite Material, the polyphenylene sulfide resin composite material is composed of the following components by weight: 33-40 parts of linear polyphenylene sulfide resin, 18.5-23.5 parts of polyamide fiber, 15-18 parts of basalt fiber, aluminate coupling 3.5-4.5 parts of agent, 5.5-8.5 parts of aluminum hydroxide powder, 1.3-2.5 parts of ammonium disulfate, 1.8-2.8 parts of silicon dioxide and 4.5-5.6 parts of anti-wear agent.

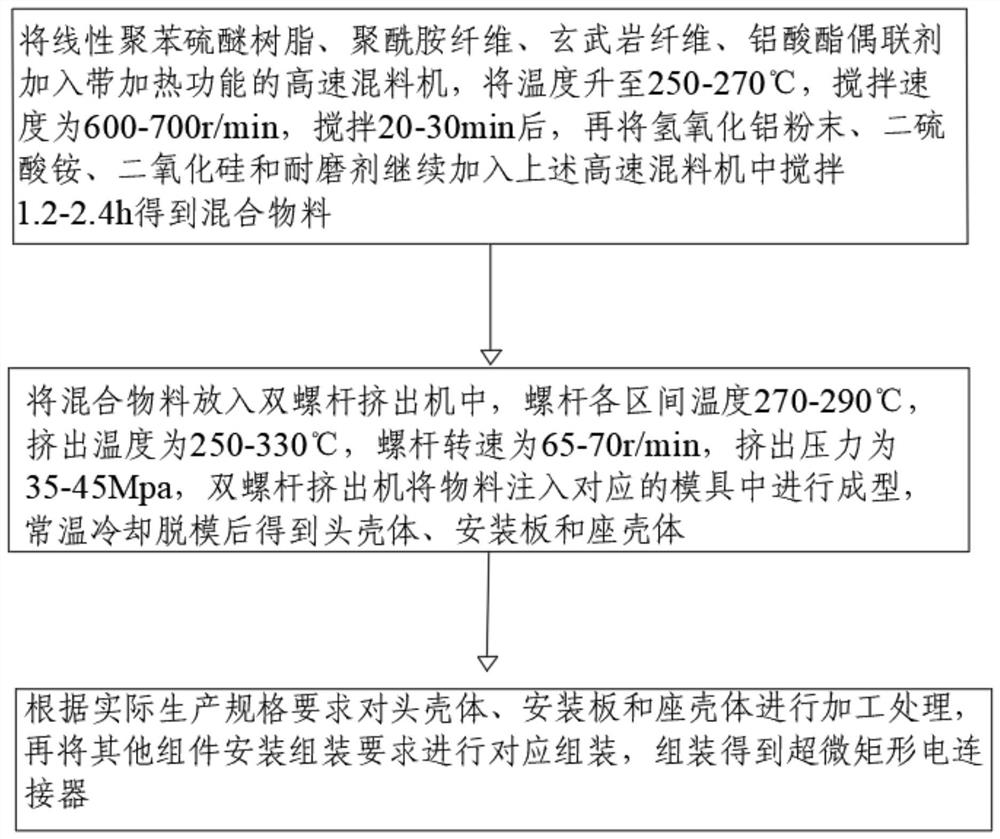

[0046] A production process of an ultra-micro rectangular electrical connector, the production process steps are as follows:

[0047] Step 1: Add linear polyphenylene sulfide resin, polyamide fiber, basalt fiber, and aluminate coupling agent to a high-speed mixe...

Embodiment 2

[0052] Embodiment 2 is a further improvement to Embodiment 1.

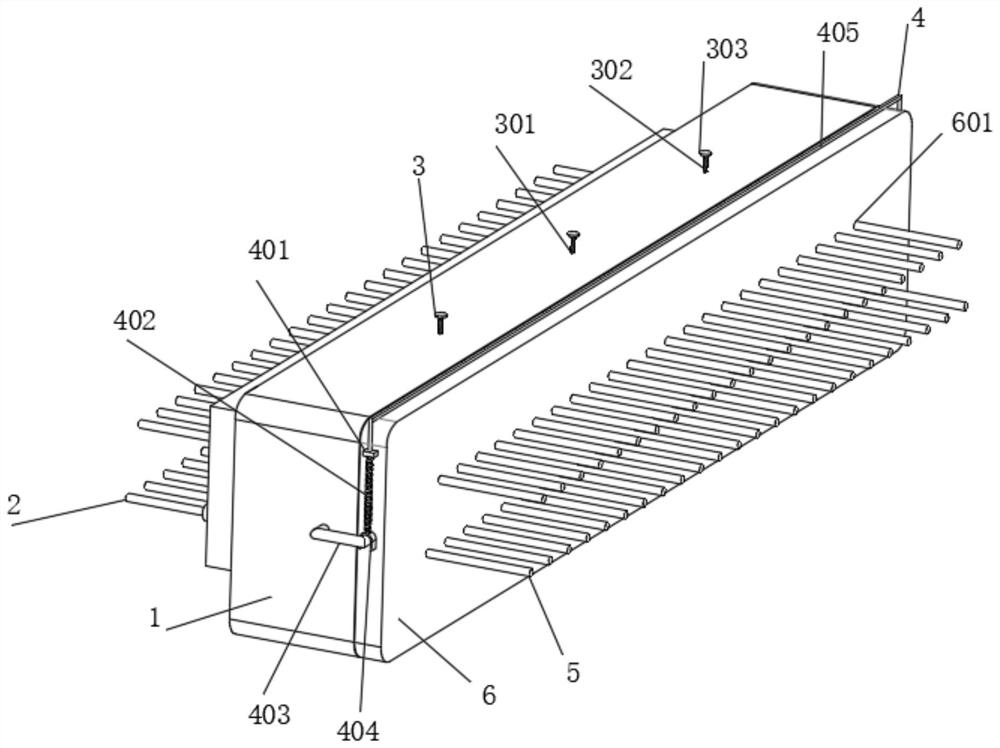

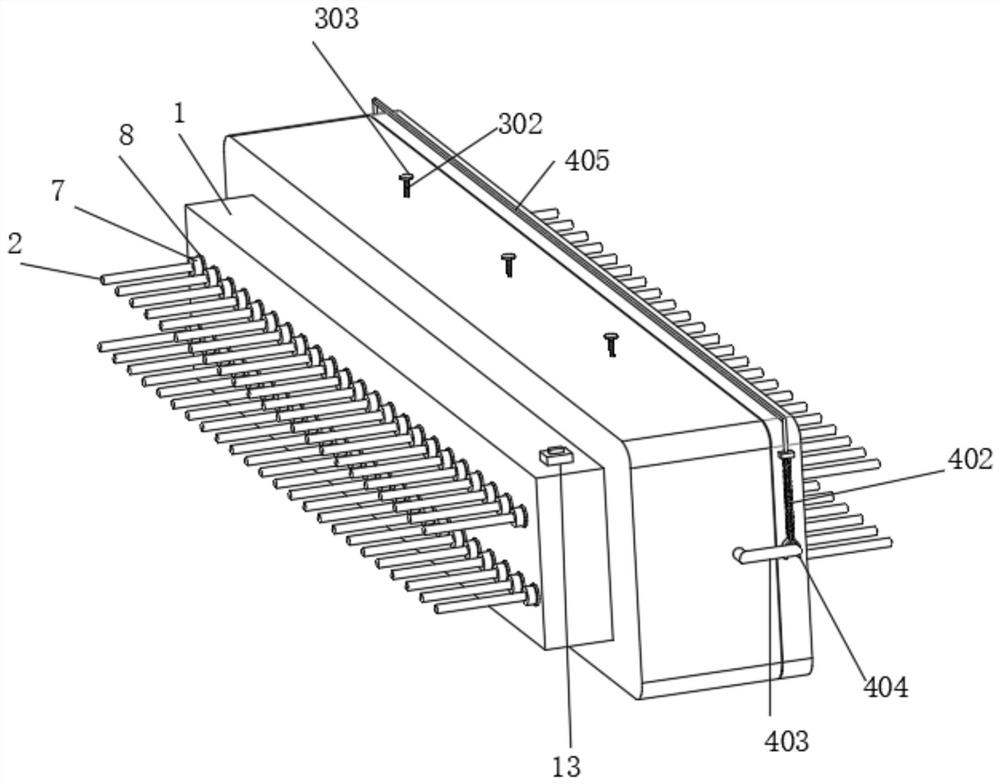

[0053] Such as figure 2 , 3 , 4, 5, 7, 8, 9, 10 and 11, the ultra-micro rectangular electrical connector obtained by the production process includes a seat housing 1, a head housing 6 and a mounting plate 11, and the head housing 6 is uniformly provided with Sliding hole 601, the second cable 5 is fitted and slidably connected in the sliding hole 601, the inner end of the second cable 5 is fixedly connected to the pin 9, the outer wall of the pin 9 is fixedly connected to the second mounting sleeve 12, and the mounting plate 11 is uniform A third installation hole 1101 is opened, and the second installation sleeve 12 is fixedly installed in the third installation hole 1101. AB glue is potted between the third installation hole 1101 and the inner wall of the second installation sleeve 12. The second installation sleeve 12 AB glue is potted between pin 9 and pin 9;

[0054] The seat shell 1 is uniformly provided...

Embodiment 3

[0058] Embodiment 3 is a further improvement to Embodiment 1.

[0059] Such as figure 2 , 3 , 6 is connected between the seat housing 1 and the first cable 2 for the reinforcement of the seat housing 1 and the first cable 2 installation structure 4, fixed block 401, the first spring 402, U-shaped block 403, n-shaped Block 404 and lifting plate 405, U-shaped block 403 is fixedly installed on the front and rear side walls of seat housing 1, the bottom of both ends of lifting plate 405 is fixedly connected with straight rod 406, and the middle and upper end of straight rod 406 is fixedly connected with fixed block 401, fixed The block 401 is fixedly connected with the head housing 6, the bottom of the fixed block 401 is fixedly connected with a first spring 402, the bottom of the first spring 402 is fixedly connected with an n-shaped block 404, and the top of the n-shaped block 404 is fixed with the bottom of the fixed block 401 When the mounting plate 11 is fixedly installed,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com