PWM signal generation circuit and method for biological sample ultrasonic treatment system

A PWM signal and ultrasonic processing technology, applied in the preparation of test samples, pulse shaping, etc., can solve the problems of frequency deviation, inflexible adjustment, consistency difference, etc., to achieve accurate frequency, simplified hardware structure, and good consistency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

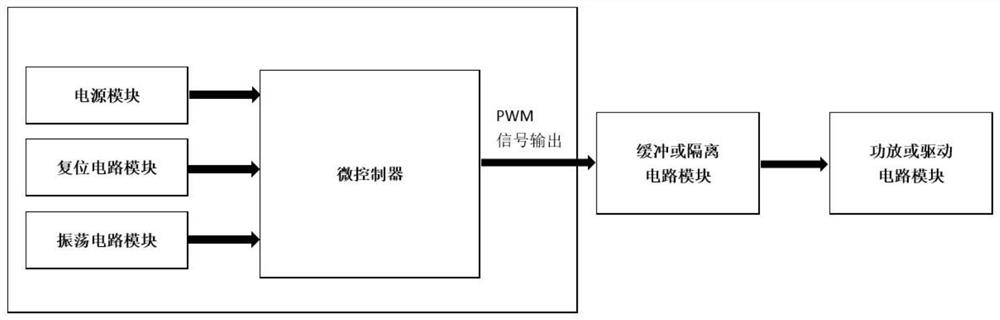

[0049] like Figure 1 to Figure 6 As shown, this embodiment discloses a PWM signal generation circuit for a biological sample ultrasonic processing system, which is used to generate a PWM signal, including:

[0050] Microcontroller to generate and output the required PWM signal;

[0051] A power module for powering the microcontroller;

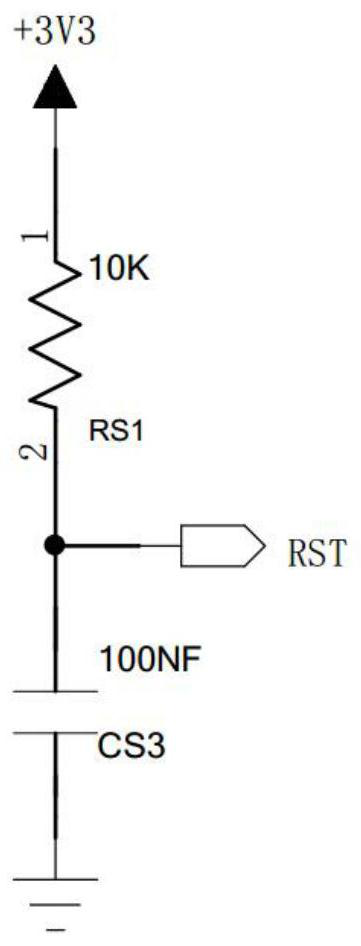

[0052] Reset the circuit module to ensure that the microcontroller can work normally after the microcontroller is initialized;

[0053] The oscillation circuit module is used to generate the basic signal source of the microcontroller's system clock.

[0054] The above-mentioned disclosed circuit takes the microcontroller as the core and the clock of the oscillation circuit as the basis. By configuring and controlling its peripheral circuits and internal circuit modules, a system clock with high stability and accuracy is obtained to drive the timer. The output frequency meets the requirements of The signal required by the biological sample p...

Embodiment 2

[0067] like Figure 1 to Figure 6 As shown, this embodiment discloses a PWM signal generation method for a biological sample ultrasonic processing system. The signal generation circuit disclosed in Embodiment 1 is applied to generate and output a PWM signal through a microcontroller, including the following steps:

[0068] The oscillating circuit module works to generate a sine wave signal and input it to the microcontroller;

[0069] According to the frequency of the sine wave generated by the oscillating circuit module, configure the microcontroller and obtain the system clock frequency; in this step, the microcontroller is configured with a timer module, and the configuration of the microcontroller is made for the timer module of.

[0070] According to the system clock frequency, configure the microcontroller and generate the same PWM signal as the required ultrasonic frequency, and output the PWM signal from the pin of the microcontroller chip in the form of high and low ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com